Proper crusher lubrication - Tip of the Week - Lube Talk

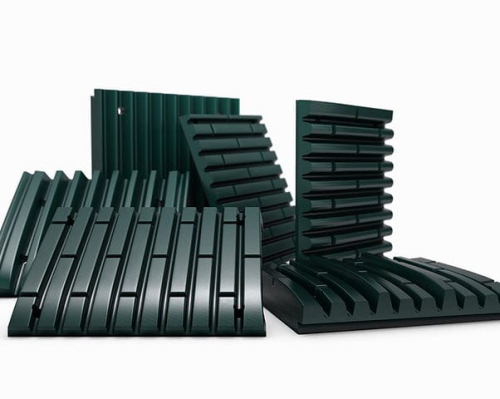

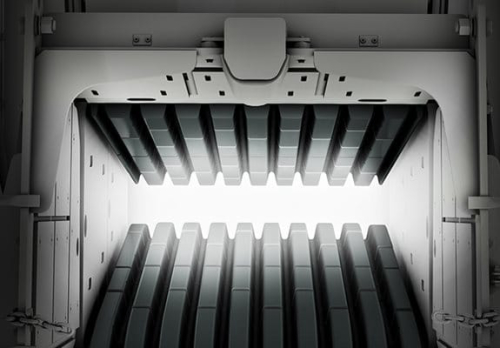

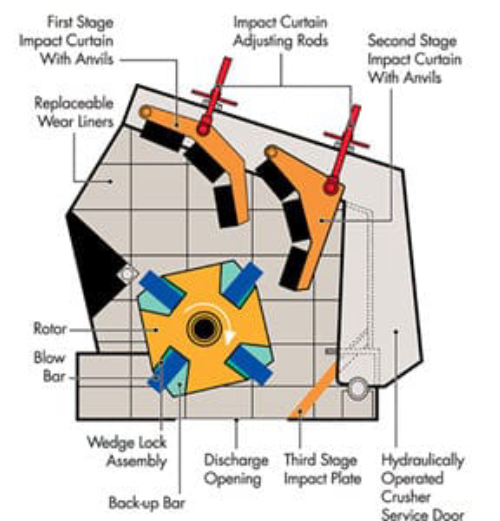

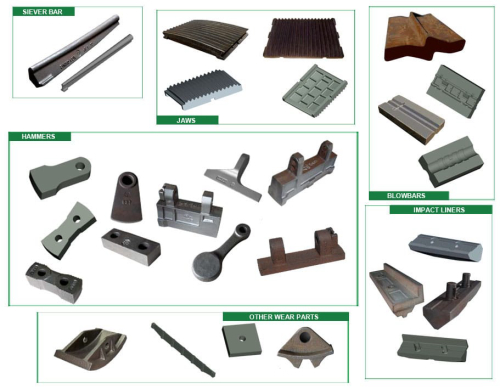

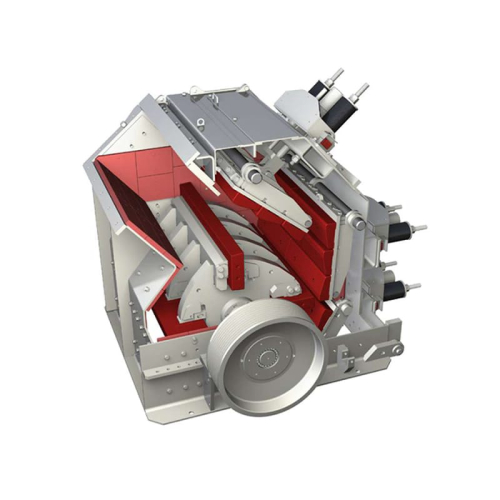

There are three main types of crushers – jaw crushers, cone crushers and impact Greases: Operators should look for lithium or calcium soap-based greases

Learn MoreChoose Suitable Grease for Jaw Crusher to Improve Production

As a first-class crushing, the jaw crusher should be regularly overhauled and maintained, pay attention to small problems, correct operation, in order to avoid unnecessary accidents, how to

Learn Moreblake type jaw crusher grease system

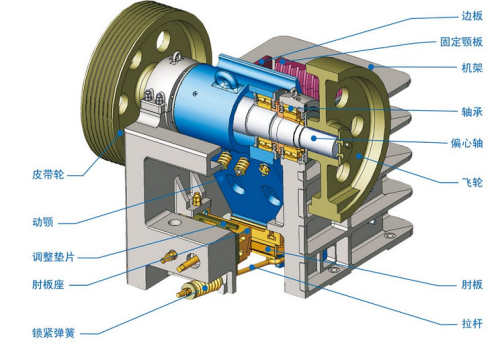

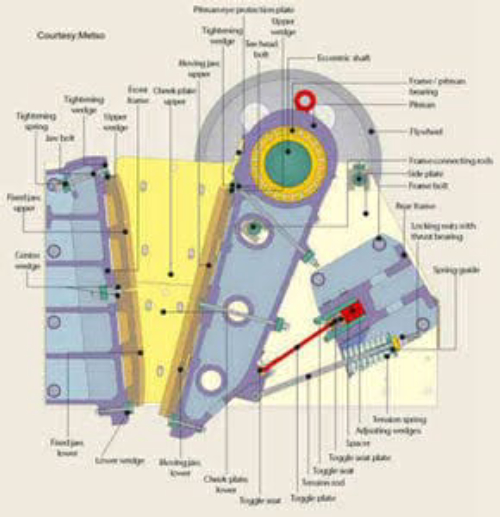

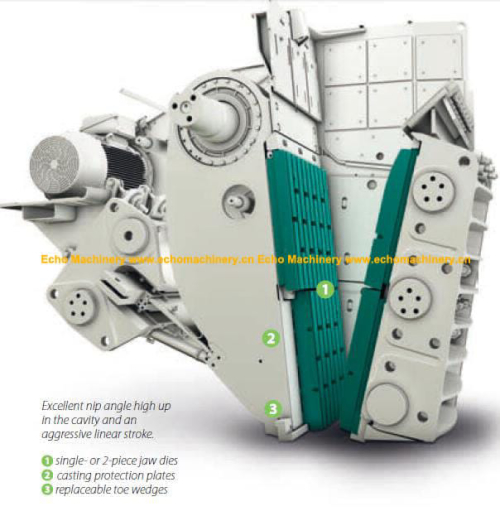

blake type jaw crusher grease system. double toggle jaw crusher explained in pakistan. Today, the most commonly used types of jaw crusher are the single toggle and the double togg

Learn MoreRe-Minder-Lubrication for SJ Jaw Crusher

Re-Minder-Lubrication for SJ Jaw Crusher · 1. Add lubricant oil, position should be correct. 8d0c58a24ceb38e5f96e6ad145480fad.jpg · 2. The

Learn MoreWhat Are Jaw Crushers And How Do They Work? - High Level Platform

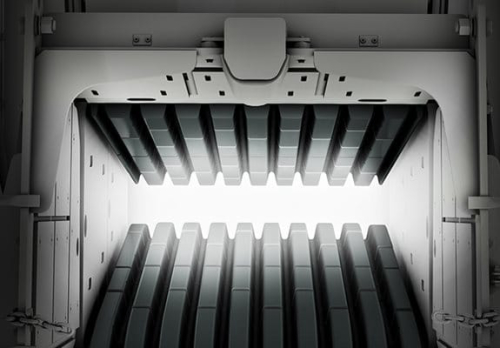

The size of these jaw crushers is determined by the square or rectangular opening from the feed opening (top of the jaws). For example, the 24 X 36 jaw crusher will have an opening of 24″ X 36″. while a 56 X 56 jaw crusher will have an opening of 56″ square. The lubrication system ensures an adequate supply of grease to each bearing

Learn MoreGlobal Mining Review - Lubricants for Compression Crushers

An example of a suitable grease for jaw crushers includes Jet-Lube Jet-Plex EP Grease. This grease is suited for both main and pitman bearings,

Learn MoreGetting the Most Out of Your Jaw Crusher - Pilot Crushtec

Over greasing; Insufficient grease; Bearing failure; Jaw overloading, too high a crushing ratio or to tight closed side setting; Incorrect grease. Figure 4

Learn MoreKeep Crushers Operating in Peak Condition

Inspection, lubrication key to proper maintenance. January 1, 2005. Asphalt Contractor Staff. Aggregate jaw crushers are built tough, but they still require

Learn MoreROCK CRUSHER GREASE | Crusher Mills, Cone Crusher, Jaw Crushers

Choose Quality Oil Type Crusher Manufacturers, Suppliers, tire&crawler type mobile rock crusher: 1.Fuel oil saving rate can reach 25%; 2.Light weight, Rock crusher lube 2-20 GPM - Flow Meter Rock crusher lube 2-20 GPM These meters have materials of construction pre-selected to be good for circulating lubricating oil.

Learn MoreWhat Kind Of Grease For Jaw Crushers

What Kind Of Grease For Jaw Crushers. Prompt : Caesar is a famous mining equipment manufacturer well-known both at home and abroad, major in producing stone crushing

Learn MoreHow does the rock crusher lubrication system work? - Quora

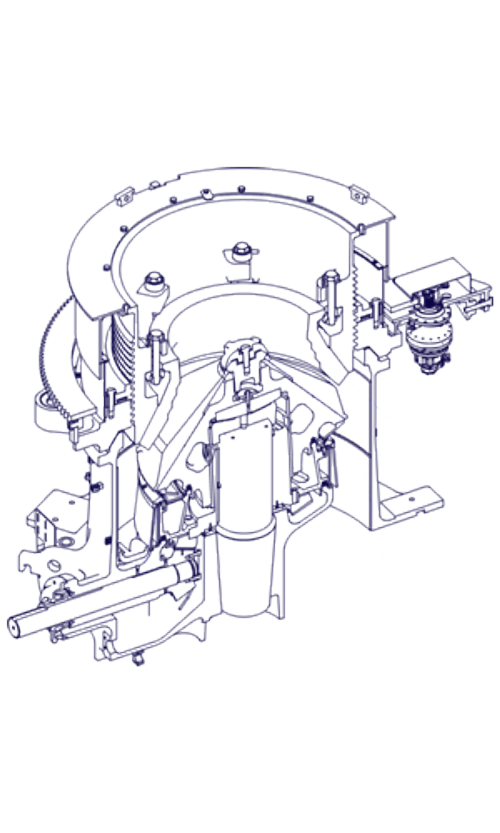

Ignoring the maintenance of the lubrication system, dust can invade the lubrication system and Are you talking about cone, gyro, jaw crusher? A sizer?

Learn MoreHow To Choose Grease For Jaw Crusher?-Fote Machinery

4. Select grease based on the working state of jaw crusher: jaw crusher vibrates intensively when it is working, and it is necessary to select the grease with high viscosity, good adhesion, and

Learn Moreashok machinery fixe jaw plate price in sri lanka | kyodo yushi grease msds

Harga 18 x 36 Cedarapids jaw crusher. jaw crusher pioneer 18 x 36 stone crusher quarry. our company is specialized in manufacturing jaw crusher pioneer 18 x 36, fixed. 6753. 18 x 24. float. 6754 el jay/cedarapids and harga machine stone crusher. Rincian lainnya atau bantuan. 50 tph Sri Lanka | Shanghai Yike Road & Bridge Machinery Co., Ltd

Learn MoreLubricating crushing machines in quarries - Rock to Road

The actual crusher can be in the form of a cone, gyratory, impact, jaw, etc. – type machine. Common to all crushers is the requirement for lubrication,

Learn MoreJaw Crusher Lubrication Schedule | Crusher Mills, Cone Crusher, Jaw

daily maintenance check list for jaw crusher. jaw crusher gyratory crusher (pivoted · Lubrication & Maintenance Schedule Jaw Crushers Model 3858 Daily Start-up Annually Start-up Monthly Hourly .

Learn MoreJaw Crusher Single Toggle Grease Base - Pinterest

KV Metal Works Jaw Crusher Gold Crush manufacture supply best Jaw Crusher Single Toggle Grease Base machines from Indore Best for stone crusher sand making

Learn MoreStone Crusher Bearing Lubrication within Mining and Cement

These may include jaw crushers, cone “gyratory” crushers and impact hammer crushers. All crushers employ bearings as part of their mounting configuration. For

Learn MoreJaw Crusher Lubrication Knowledge Analysis | 2019-09-10 - DC Velocity

For example, the jaw crusher's dynamic suspension shaft bearing and the thrust plate elbow are lubricated without oil return, so intermittent grease is required. The bearing of the small jaw-type crushing motorized suspension shaft adopts the oil cup and lubricating oil, so it can be used once in 30-40min.

Learn MoreHigh Reduction Ratio Crusher - 911 Metallurgist

Jaw Crusher. Model #JCT#1AL. The lubrication system is set to grease the correct amount every 60 minutes irrespective of whether the machine is continuously

Learn MoreProper crusher lubrication - Tip of the Week - Lube Talk - Mobil

In some cases, operators may use greases that contain a molybdenum disulfide additive to protect against adhesive wear. Most crusher bearings should be frequently re-greased to ensure proper lubrication and the purging of external contamination. I hope that this tip provided a helpful summary of proper crusher lubrication.

Learn MoreCrusher Bearing Grease | Crusher Mills, Cone Crusher, Jaw Crushers

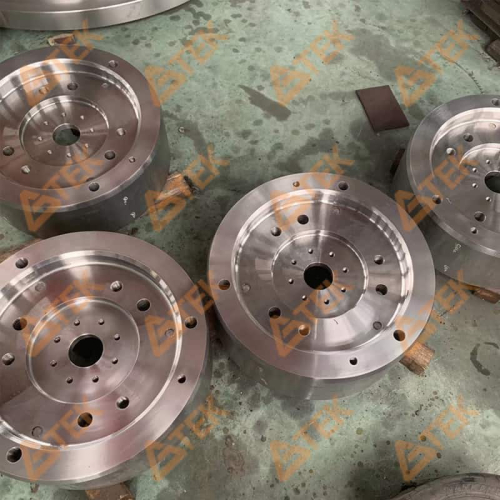

How to Repair Jaw Crusher? 3, adding 50-70% of the total amount of bearing grease, must be replaced every three Operating Manual of Jaw Crusher Machine (1) Preparation work before Jaw Crusher Machine starts: 1.1 Carefully check if bearing is of good duplication, make sure bearings inside cubits board have enough joint grease.

Learn MoreUS2975865A - Jaw crusher lubrication - Google Patents

The improved lubricating system specifically shown and described herein has gone into highly satisfactory and successful commercial use as applied to a jaw

Learn MoreGrease Base Jaw Crusher Manufacturer,Supplier,Exporter

We are the leading manufacturer and supplier of Grease Base Jaw Crusher. Offered crushers are widely used for crushing hard granites stone, black trap rock,

Learn MoreGrease Base Single Toggle Jaw Crusher in Indore - KV Metal

One jaw is Side Plates fixed and the other jaw is fitted on swinging lever. The side plates are of close fitting type which prevents wear & tear to the main body. Lubrication : Roller grease is used as lubricant in bearings to ensure smooth working. Grease moves outwards from bearings & grease nipples are fitted at appropriate places.

Learn MoreCrusher Bearings: - Timken

Compression Crushers. 2. Jaw Crushers. 2. Cone Crushers. 2. Impact Crushers. 3. Better Bearing Care. 3. Lubrication. 3. Bearing Fit on Shaft and in Housing.

Learn MoreCrusher Lubricant™ ISO 220 - Products

D-A Crusher Lubricant™ provides excellent performance in gyratory, cone and jaw crushers. It is also well suited for use in screen gearboxes and bearings

Learn MoreOrdinary Jaw Crusher - 911 Metallurgist

Lubrication of ordinary jaw crusher is usually attempted by one of several methods, such as grease, ring oiling or oil circulated by pump

Learn Moreid/c125 jaw crusher lubrication.md at main · /id - GitHub

C125 jaw crusher cz eu.C96 C100 C80 2 3 Table of Contents High quality,All C Series jaw crushers,c125 jaw crusher lubrication, Mining and. And

Learn MoreJaw Crushers - AGGRETEK portable jaw crushers

Jaw Crushers Shaft & Bearings The larger eccentricity of pitman shaft provides a motion that pulls the material to the bottom of the jaw plate. Crushing Power Wide range of crushing for soft to very hard materials. For various materials, crushing efficiency is increased by different jaw types. Adjustment

Learn Morerecommended grease for jaw crusher bearing - Panola Mining

Recommended heavy-duty #2 grease. 1. The jaw must be greased once every eight (8) hours of operation on the two nipples of the movable jaw above toggle and below motor base. 2. Grease the two (2) side bearing nipples located on either side of the crusher. The nipples have been extended up to make servicing easier. This should also be done every.

Learn MoreGrease Base Jaw Crusher

Jaw Crusher is mainly used to crush kinds of mining stones primarily, Calcium base grease, Sodium base grease, and calcium-sodium base grease can be used. how much grease for a

Learn More

Leave A Reply