crushing chmabers liners replacement muncie m22 rock crusher eccentric

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

Learn MoreConstant Wear Criterion for Optimization of the Crushing

chamber. Li et al. [23] examined the functional relationship between liner wear and cone crusher structure parameters by simulating the

Learn Morecrushing chmabers liners replacement mobile crushers parts sale near osaka

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

Learn MoreCone Crusher Liners: How to Select and When to Change

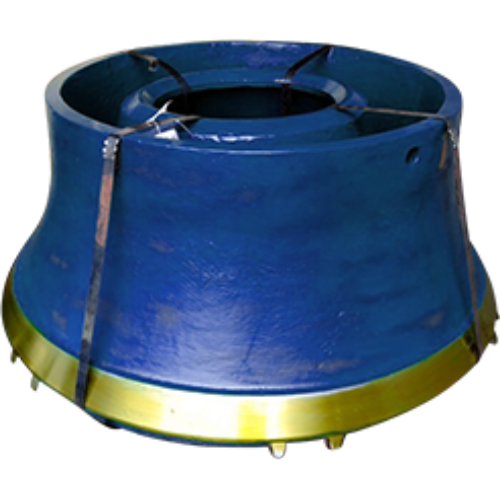

If the liner is wearing evenly throughout the chamber, you should consider changing it when it has worn down to about 1” (2.5 cm) thick at the

Learn Morecrushing chmabers liners replacement | crusher partscfunction of

About Crushing; Jaw Crushers. 2054 Jaw Crusher; 2236 Jaw Crusher; 2442 Jaw Crusher; 3042 Jaw Crusher; 3054 Jaw Crusher; 2036 Feeder Screen Jaw Plant; CJ612 4448

Learn Morecrushing chmabers liners replacement | compressor

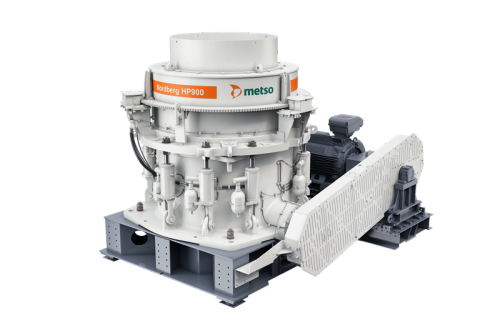

According to the advanced crushing principle, the crushing chamber and the crushing cone are quickly The hydraulic cone crusher is an ideal crushing device for medium and fine

Learn Morecrushing chmabers liners replacement | din 25201 standard pdf

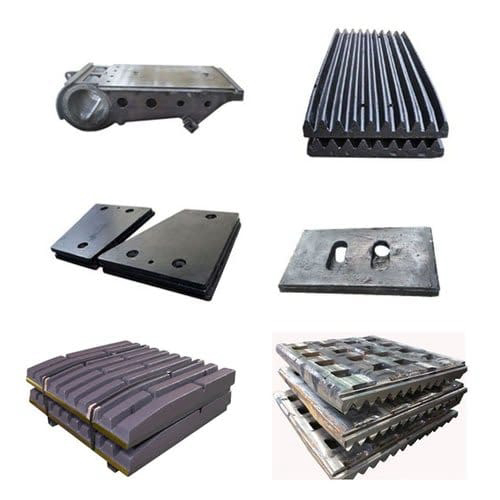

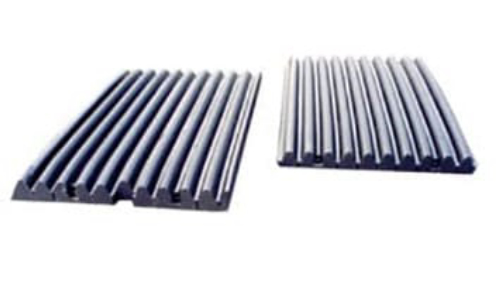

The other significant factors relate to the crushing chamber itself. Having the wrong crushing chamber – the fit between the concave and mantle, combined with the eccentric throw – can

Learn MoreWhat affects liner life? - Mining and Rock Technology

Having the wrong crushing chamber – the fit between the concave and mantle, combined with the eccentric throw – can reduce liner life by 50%.

Learn MoreAnglo American's Kolomela mine reduces liner replacement

The longer it takes to replace the wear parts inside the chamber of a their primary gyratory crusher concave liners replacement time.

Learn Morecrushing chmabers liners replacement replacement wear parts of cone crusher

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

Learn MoreGyratory Crusher Services I Service

Rock-Box Spider Cap & Arm Liner · Crushing Chamber Optimization · Wear Parts Optimization · Crusher Perfomance Reporting & Consulting · Mounting

Learn Morecrushing chmabers liners replacement | TS500 ANTI-CLOGGING SCREEN CLOTH

Easy to transport mobile concrete plants have axles and tires in its main chassis. Thanks to pre-assembled structure, they can be installed in a very short period of time (1-2 days) View Details

Learn Morecrushing chmabers liners replacement | vibrating screen socket liner

Replacement Of Cement Ball Mill Shell Liners. Replacement of cement ball mill shell liners.Mtw series heavy type european grinding.Output size 1.6-0.045 mm, the fineness is 0.038mm

Learn MoreCone Crushers | Moore Watson Ltd

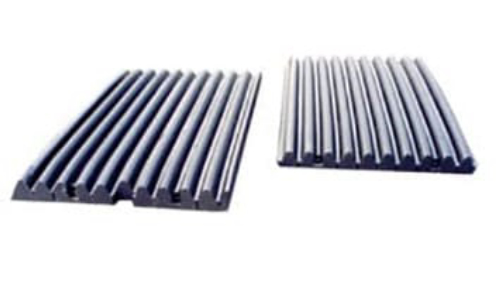

MHP series chamber can be easily changed from standard extra coarse to short head extra fine by replacing the concave liner, mantle liner, adapter ring,

Learn MoreCrusher Concave Liners and Mantle Wear - 911 Metallurgist

Unfortunately to get the most from the equipment requires that there is one hundred percent we the parts before they are replaced. A

Learn MoreChimney liners for sale - sjv.yukkuri.shop

fuel pump relay replacement; Enterprise; addictive drums reaper; ssc sports 6 live; rcw nvol with id; conan gray instagram; harbor freight power tools; Fintech; signs of neglect in a relationship; buzzfeed family; canon mf642cdw; the hemp company australia; 1980 honda cb 1000 for sale; Climate

Learn Morethe effect of liner we gyratory crushing – a dem case study

measured concave and mantle liner we gyratory crusher production. The crushing chamber profile and gap have a direct influence on.

Learn MoreCrushing Chamber - an overview | ScienceDirect Topics

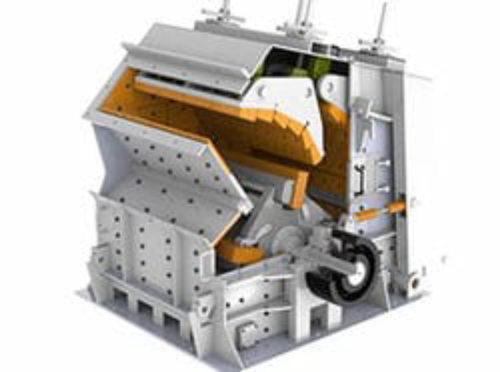

Replace device of hammers: equipped on the lifting bracket of the crushing chamber. c. Water pump: used for the external water supply of the dust removal

Learn MoreSelecting crushing chambers for cone crusher - Outotec

Crushers are equipped with wear linings that must be replaced periodically to ensure the integrity of the equipment and good performance. Jun 9,

Learn Morecrushing chmabers liners replacement crusher parts sweden

crushing chmabers liners replacement air filter 504-2s 5 micron weir crusher screen parts Construction, Working and Maintenance of Crushers for. For primary crushing

Learn MoreWhat affects liner life? — SRP - rockprocessing

Having the wrong crushing chamber – the fit between the concave and mantle, combined with the eccentric throw – can reduce liner life by 50%. Choosing the wrong

Learn MoreTrio® CT Series Jaw Crushers - The Weir Group

Fore more information about our range of jaw crusher wear parts and liners, contact our team today. Long Crushing Chamber. The long crushing chamber

Learn Morecrushing chmabers liners replacement | Z036 ELCTRC SW

crushing chmabers liners replacement | HP400 BOWL ASSY STD. feed crusher machine price list buy buy in finland bronze parts for crushers small stone crusher machine price. z036 nut

Learn Morekegelbrekers.pdf - Lutze Process

chamber and eccentric throw. Our cone crushers are ideal for secondary and tertiary crushing. CLP crushing chamber. CLP stands for Constant Liner

Learn MoreEvaluation and prediction of reliability on liner based on time

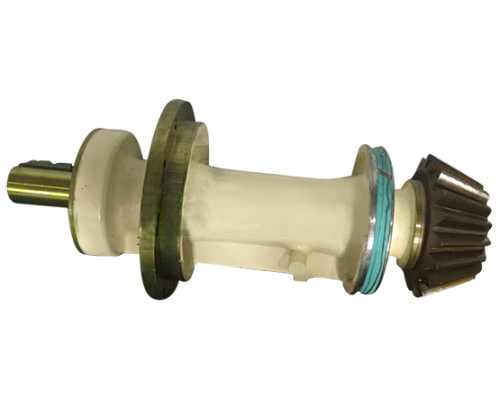

The maintenance costs which is caused by replacing worn parts is high [4]. crushing chamber is formed by bowl liner, mantle, eccentricity and location

Learn Morecrushing chmabers liners replacement | TS500 ANTI

Easy to transport mobile concrete plants have axles and tires in its main chassis. Thanks to pre-assembled structure, they can be installed in a very short period of time (1-2 days) View Details

Learn Morejwc.drakeseliquid.de

A factory timing chain, tensioner and guides cost about $269, and a Cloyes timing chain set costs about $141. The total timing chain replacement cost would be about $859 using OE parts, or about $710 using aftermarket parts. In all of the. 2020. 8. 7. · The average cost for timing chain replacement is between $1,217 and $1,468. Labor costs are. .

Learn Morecrushing chmabers liners replacement | lower head bushing catalog for

crushing chmabers liners replacement reduces downtime and improves safety in Kumba. Mar 14, · A major factor affecting crusher efficiency is the amount of downtime. The longer it takes to replace the wear parts inside the chamber of a primary gyratory crusher during a maintenance shutdown, the less uptime and, thus, less production.

Learn Morecrushing chmabers liners replacement | best barley crusher

Having the wrong crushing chamber – the fit between the concave and mantle, combined with the eccentric throw – can reduce liner life by 50%. Choosing the wrong mantle can cause a

Learn Morecrushing chmabers liners replacement | inner eccentric bushing simmons

crushing chmabers liners replacement. Cone Crusher - an overview. Maintenance of the wear components in both gyratory and cone crushers is one of the major operating costs. Wear monitoring is possible using a Faro Arm (Figure 6.10), which is a portable coordinate measurement machine.Ultrasonic profiling is also used. A more advanced system

Learn Morecrushing chmabers liners replacement eccentric bushing replacement of

crushing chmabers liners replacement eccentric bushing replacement of crusher Yong Won SP300 Super Cone Crusher liner replacement. Performance cone crusher liners from FL not only provide consistent, high-rate production and longer wear life, but they also protect your crusher from If cone crusher differs then it is only from crushing chamber.

Learn More

Leave A Reply