BALL MILL LINER -PRODUCT - HUIHE MININGPARTS CO

HUIHE MININGPARTS CO., LTD - Mill liners is used in the steel ball mills/rod mills to protect the body of mills and also designed

Learn MorePDF) Ball mill Polymet liner evaluation at PT Newmont Nusa

PDF | The grinding circuit at PT Newmont Nusa Tenggara (PTNNT)-Batu Hijau mine consists of two SABC (semi-autogenous milling, ball milling,

Learn MoreMill Linings for Sale, Types of Ball Mill Liners. - ball mills supplier

Ball Mill Rubber Liner, The rubber linings produced by AGICO CEMENT can generally be divided into ball mill rubber linings, rod mill rubber linings, tube mill rubber linings, AG mill

Learn MoreBall Mill Liner

offers 2286 ball mill liners products. A wide variety of ball mill liners options are available to you, such as material, applicable industries,

Learn MoreMill liners - Outotec

Mill liners optimized to meet your targets · Steel, Poly-Met™, Megaliner™, Rubber and Orebed™ mill liners for all mill types · Performance targets: · Continuous

Learn MoreForged Ball Mill Liner Bolts | Greg Sewell Forgings

Forged Mill Liner Bolts. Greg Sewell Forging designs and manufactures the highest quality SAG and Ball mill liner bolts, and by equally distributing the elongation load you can prolong the life of each bolt, reducing the amount they will need to be replaced. We recommend true oval type head bolts or “lune” type over the square oval type

Learn MoreBall mill liner - WALDUN

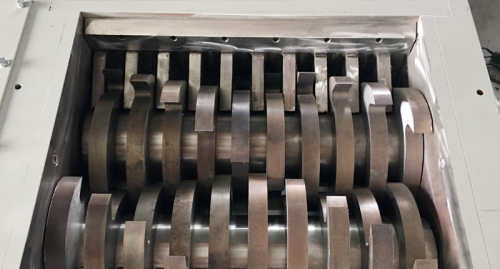

Ball mill liner. Ball mill liner is used to protect the cylinder so that the cylinder from the abrasive body and material direct impact and friction, but also use different forms of the liner to adjust the movement of the grinding body state, to enhance the grinding body of the material crushing effect, help improve the grinding efficiency of the mill, increase production, reduce metal

Learn MoreWear-resistant mill liner, ball mill liner and SAG mill liner for

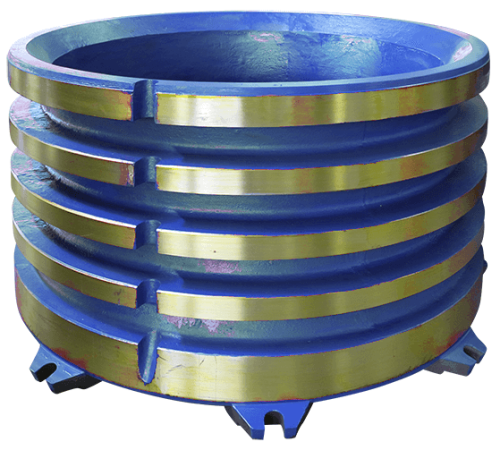

High manganese mill liner. Material: Mn13, Mn13Cr2, Chromium alloy steel, rare earth wear-resisting steel Process: lost mold Applicable machinery: ball mill, vertical mill, mill, mill, crusher Performance advantages: 1.Using modified high manganese steel and super high manganese steel, has enough impact toughness.

Learn MoreBall Mill Liner Bolt Manufacturer,Supplier and Exporter from India

We are presenting an exclusive array of Ball Mill Liner Bolt. Our offered bolt is widely applicable in various industries. By utilizing progressive technology and quality-proven materials in manufacturing, we provide perfect finishing and durability to our Ball Mill Liner Bolt.

Learn MoreHome [ballmillrubberliner.com

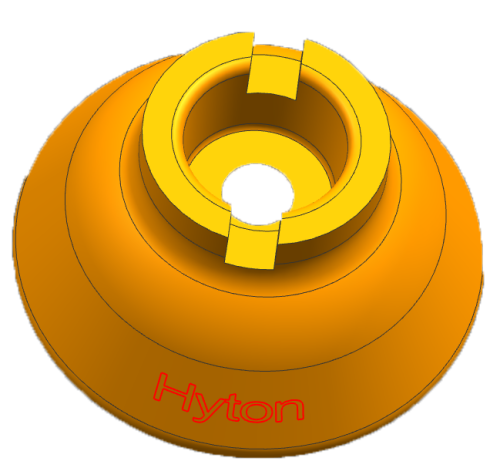

This product is an important part for conical ball mill and its call "feed end liners for ball mill' its main function is to protect the end cover of ball mill. The high wear-resistance head liner Read More . SIDE WALL CIRCLE. This product is also call blind disk for Ball Mill. It is a round plate which has all of the relevant bolt holes but

Learn MoreBall Mill Liners Market Analysis, Forecast, Size, New Trends and

The MarketWatch News Department was not involved in the creation of this content. (Reportmines via Comtex) -- Pre and Post Covid is covered and Report Customization is available. This

Learn MoreGrinding Media, SAG Mill Liner, White Iron Mill Liner - H&G

High manganese steel mill liner Mn13Cr2 will be sent to Russia H&G deliver 2 sets of high ma Mn13Cr2 high manganese steel ball mill liner is Sep-18- . Mn13Cr2 high manganese steel ball mill liner is ready for shipping H&G deliver 2 sets of hig High manganese steel ball mill liner arrived In Sep-18-

Learn MoreBall Mill / SAG Mill Steel Shell Liners - Unicast Inc

Ball Mill / SAG Mill Steel Shell Liners Unicast Shell Liners are cast in materials ranging from chrome-moly steels to high chrome white iron. A minimum

Learn MoreHow to Replace the Ball Mill Liner?

The ball mill liner is intended to protect the barrel of the ball mill in order to reduce and avoid direct impact and friction of the body and abrasive minerals on the barrel of the ball mill. The

Learn MorePolycorp - Ball Mill Liners

These liners are custom designed for your mills. Mining, Ball Mill Liners, PolyStl™ Liners, PolyStl™ liners are composite of Special Wear Resistant Steel and High Pressure Moulded

Learn MoreSAG & Ball Mill Liner - Tega Industries

Tega DynaMax · Tega has more than 500 grinding mills lined globally in SAG, AG, Ball, Primary and Secondary milling applications lined with Rubber Liner and

Learn MoreLining arrangement for ball mill - Google Patents

A ball mill sleeve assembly in which ball mill drum is mounted, wherein the plurality of wear resistant liners (1) and the self-attaching bushes (2) are

Learn MoreHow to Replace the Ball Mill Liner?

At this time, it is necessary to replace the new ball mill liner. The ball mill liner is intended to protect the barrel of the ball mill in

Learn MoreSteel-casted mill liners for mining - Fundiciones Estanda

Metallic liners for all kind of SAG mills, AG, ball mills and rod mills present in the grinding processes of minerals. Liners profile design upon client´s

Learn MoreCraig Loren Mills Obituary (1946 - 2022) | Hillsboro, OR - Echovita

Family and friends must say goodbye to their beloved Craig Loren Mills (Hillsboro, Oregon), born in Portland, Oregon, who passed away at the age of 75, on June 27, 2022. You can send your sympathy in the guestbook provided and share it with the family. He was predeceased by : his parents, Loren Mills and Harryette Lee Mills (McCarthy); and his

Learn MoreBall Mill rubber Liner| Ball Mill Rubber Lining

Our Ball Mill Rubber Liners are designed to avoid unnecessary downtime and service intervals which results in easy inventory control and reduces the grinding cost. Sakar's Ball Mill Rubber Liners are design by using state-of-the-art software-driven with industry-leading inspection data, achieving an optimal charge trajectory and rate of wear

Learn Moreliners crusherball liners mill -- earna

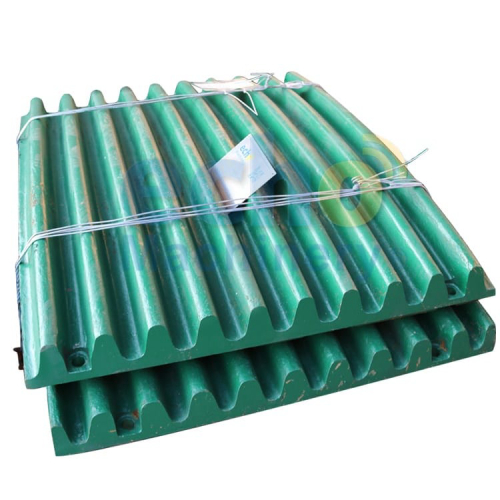

Ball Mill Liner Design Mineral Processing amp Metallurgy. Jan 05, The liners are from 50 to 65 mm thick (2″ to 2.5″) with the waves from 60 to 75 mm (2.5″ to 3″) above the liners.

Learn MoreBall Mill Linings - Multotec

Ball Mill Linings from Multotec provide optimum wear lining solutions for the toughest applications, ensuring optimum grinding and crushing efficiency.

Learn MoreThe effects of lifter configurations and mill speeds on the mill

materials, which are utilized for mill liners and grinding balls. liner spacing and detrimental ball-on-mill impacts is potentially decreased by

Learn MoreRubber Ball Mill Liner - Strudex Mining

What is rubber ball mill liner? The ball mill liners are located on the inner surface of the ball mill barrel, which protects the barrel from the direct impact and friction of the grinding media

Learn MorePRESSURE GAUGE | ball mill wear socket liner

General Tech Services LLC. ADDRESS. General Tech Services L.L.C Head Office: P.O. Box: 25898 Sharjah, U A E Tel: +971 6 5436933 Fax: +971 6 5437077 Email: [email protected] Website Pressure Gauge EA729-3 | ESCO

Learn MoreMill Liner plate - mill linings Latest Price, Manufacturers

These liners are used in Ball mills where low contamination is required. Contamination with Alumina Ceramic lined ball mill is low due to their extremely low

Learn MoreBall Mill Liner Function - Wear Parts For Industry | Qiming Casting

Ball mill liner plays a major role in protecting the inner wall of the anchor windlass. Different shapes of the ball mill lining plate can improve the grinding effect of the ball mill and improve the working efficiency of the ball mill. 1, flat ball mill liner, the surface smooth, suitable for installation in the fine grinding warehouse.

Learn MoreBall Mill Liner ( Rubber , Polyurethane ) | Mill Rubber Linings Plate

The Lining Plate Of Ball Mill Is Gradually Replaced By Rubber And Polyurethane Lining Plate In China, But With The Continuous Application Of Rubber Polyurethane Lining Plate In The Lining Plate Of Ball Mill, It Has Gradually Replaced Manganese Steel And Other Lining Plates And Become The Mainstream Of Market Development. Categories: Mill Liner.

Learn MoreEfficiency Improvement Of Ball Mill Liners By Simulation Of

A plant audit at the Sarcheshmeh copper complex indicted that due to the inappropriate design of ball mills liners, the liners wear and tear increased and

Learn MoreLow Alloy Steel Ball Mill Liners Design - Qiming Casting

Jul 09, · The low alloy steel ball mill liners studied in this paper have high hardenability and high tempering stability. After quenching at 850-930 ℃ and tempering at 200-290 ℃, finely tempered lath martensite is obtained, which makes the steel have high strength, high toughness and high wear resistance. The higher the hardness, the smaller the

Learn More

Leave A Reply