Jaw Plate Material Selection - Wear Parts For Industry | Qiming

Jaw Plate Material Selection The impact of jaw plate wearable reason is mainly wear-resistant material hardness and toughness. ① material is too hard, the material extrusion depth is

Learn MoreWear and Failure Principle of Jaw Plate | Qiming Casting

Wear failure process. ① material repeatedly squeeze chisel teeth plate, in the jaw plate surface, or in the extruded metal protruding part of the root to form micro-cracks, the micro-cracks

Learn MoreStandard Jaw Plates | Vise Jaws & Jaw Plates | Kurt Workholding

All jaw plates are sold individually. Standard individual jaw plates are additional or replacement jaw plates for standard 4”, 6”, 8”, and 10” vises. Hardened and soft jaw types are available. Find stepped and serrated jaw plates in the InnerLock system. Showing all 18 results.

Learn MoreJaw Plate, Teeth Plates, Jaw Crusher Wear Parts for Sale - Willing

Because of the use of manganese content of 13% to 30% of the high manganese steel and ultra-high manganese steel, and the unique heat treatment, our products possess strong wear resistance and long service life. Our jaw plates are widely used on mining, construction, chemical, cement and metallurgical industry. Details Videos Downloads Parameters

Learn MoreMaterial Selection of Jaw Plate of Jaw Crusher

The material of the jaw plate should meet the requirements of high hardness and high toughness. However, the toughness and hardness of materials are often contradictory. Therefore, it is necessary to fully understand the working conditions and select materials reasonably. 1. Improve the hardness of the jaw plate

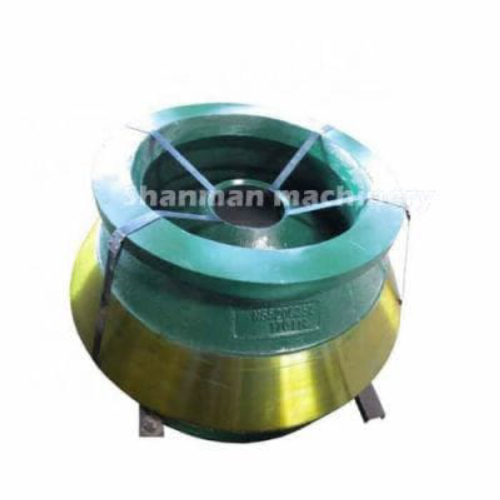

Learn MoreJaw Plate - Crusher Wear Spare Parts

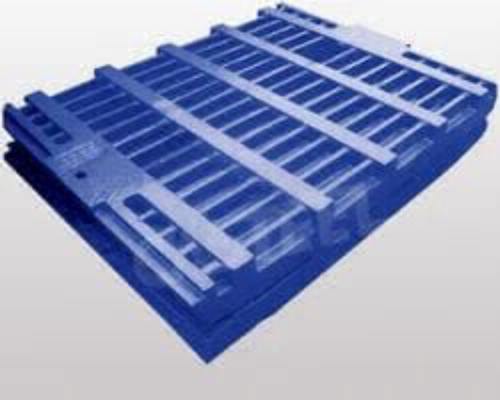

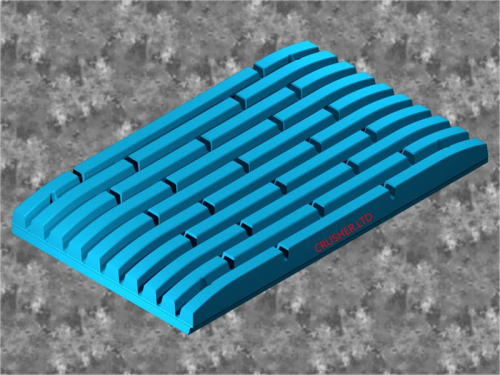

Name: Jaw plate (movable plate, fixed plate), tooth plate, tooth plate Main Material: High manganese steel, manganese chromium alloy (Mn13, Mn13Cr2, Mn18, Mn18Cr2), hard alloy. Casting Process: Sand modelling casting,Evanescent mode casting Application

Learn Morejaw plate material | stone crusher parts suppliers near mong kok

The Jaw plates have 6 kinds of material to choose. EXPERIMENTAL EFFECT ON JAW CRUSHER PLATE. Jaw crusher jaw plate overview:- Jaw plate is manufactured with super high manganese steel, therefore it has a service life 50~100% longer than those made of traditional high manganese steel.

Learn MoreMovable Jaw Plate Casting Manufacturers - EB Castworld

Movable Jaw Plate Casting Manufacturers Name: Movable Jaw Plate MOQ: 1 pieces Hardness: 48-62 HRC Elongation: 30 – 50% Delivery time: 7-30 days/ negotiation Size: Customize Advantage: Wear Resistant Manganese Contents: Mn13Cr2, Mn18Cr2

Learn MoreNews - Jaw Plate Manufacturer & Supplier & Casting Foundry

Alloy Steel jaw plates. TIC insert jaw plates. As a casting foundry, no matter which material you need, you can contact our engineers to help you get the right choice. 2. We supply full reports for every part of the jaw plate. After finish your orders, we will supply all full reports to you. you can check the reports in the home.

Learn Morejaw plate material | for roller bearing jaw crusher

In the working process of jaw crusher, jaw plates (tooth plates) are the parts that directly contact the raw material. Material Selection for Crusher Jaw in a Jaw Crusher Equipment. The distinctive feature of this class of crusher is the two plates which open and shut like animal Jaws (Grieco and Grieco, 1985), this jaw is Stainless steel

Learn MoreFIXED JAW PLATE-Bogvik Wear Material

Shanghai Bogvik Wear Material Co., Ltd is one of the most professional crusher parts manufacturer an +86 158 5198 9372 丨

Learn MoreWhat are the Materials of the Jaw Crusher Plates and Which is Better

High manganese steel is the traditional material of the jaw plate of jaw crusher, which has good impact load resistance. However, due to the structure of the crusher, the opening angle between the movable and fixed jaws is too large, which is easy to cause abrasive sliding and deformation due to deformation.

Learn MoreJaw Crusher Plate Material - MGS Casting

3/25 · Jaw Crusher Plate Material. The heavy duty machines use in the first mechanical stage of comminution are mainly jaw crushers. The distinctive feature of t his class of crusher is

Learn MoreJaw Crusher Parts - Wear Parts For Industry | Qiming Casting

Material types for jaw plates. There are 4 types of jaw plates materials: Manganese steel. Manganese steel, also called Hadfield steel or mangalloy, is a steel alloy containing 12-14% manganese. Renowned for its high impact strength and resistance to abrasion in its hardened state, the steel is often described as the ultimate work hardening

Learn MoreJaw Liners, Jaw Plate Material And Manufacturer | Quarrying

Jaw crusher liner material In general, the jaw plate is made of high manganese steel. The manganese steel content of Rayco’s products ranges in 12-14%, 18% and 20%. Jaw crusher liner manufacturer In the mining crushing and screening industry Most

Learn MoreJaw Plate - Casteel Foundry

Jaw Crusher Wear Parts: Item Names: Jaw Plate s ,Stationary Jaw Tooth, Movable Jaw Die Fixed Jaw, Swing Jaw Plate ,Jaw Fixed, Jaw Moveable , Cheek Plate , Side Plate Casting

Learn MoreWhat is the best material for crusher jaw plates?

12/23 · TIC Insert Jaw Plates. This material is developed by Qiming Machinery, it has improved our customer jaw plate by TIC (titanium carbide) insert. Compare with normal

Learn MoreChina Jaw Crusher Jaw Plate Material Manufacturers and Suppliers

We're hunting forward to your check out for joint development for Jaw Crusher Jaw Plate Material, Impact Crusher S, Gp200s Cone Wareparts, Mn13% Rolling Mortar Wall,Hti 1014 Scale Board. We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you.

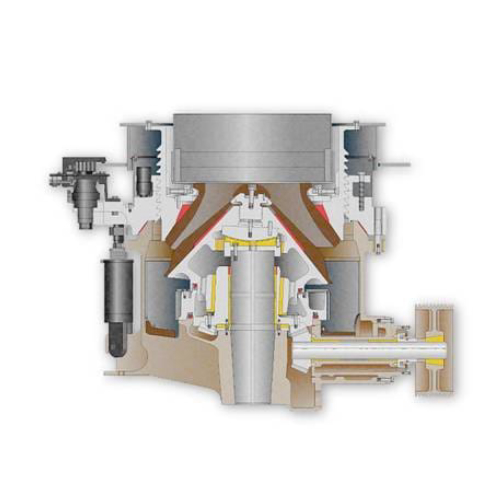

Learn MoreCrusher Jaw Plates For Popular Brands By Hunan JY Casting

The crusher jaw plates are the main wear-resistant parts installed on the machine body to squeeze and crush the stone. Normally, it consists of a 1 piece fixed jaw plate and a 1 piece movable jaw plate. In order to rotate and exchange more easily, movable jaw plates also have 2 segments design and 3 segments design.

Learn MoreSelection Of The Material Of Jaw Crusher Plate - Jaw Crusher Wear Parts

Therefore, large jaw crusher tooth plate is usually used ZGMn13Cr2 modified high manganese steel. For the jaw plate material should be selected high hardness materials to resist extrusion, micro-chisel failure, and also have sufficient toughness to resist the chipping impact fatigue failure.

Learn Morejaw plate material | group

For example, generally the jaw plate of single toggle jaw crusher is not good at crushing strongly abrasive and hard stone material with large production. Jaw plate material. Tag: Jaw plate material. How Long Can the Jaws of the Jaw Crusher be Used. Parts. The movable and fixed jaws of the jaw crusher are in direct contact with the materials

Learn MoreJaw Plates | Jaw Dies - Crusher Wear Parts - Hongfei Machinery

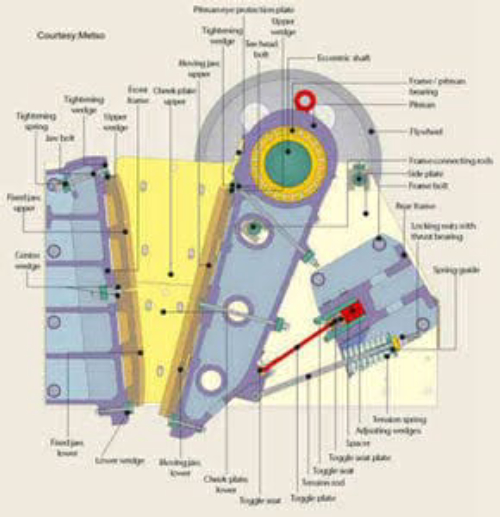

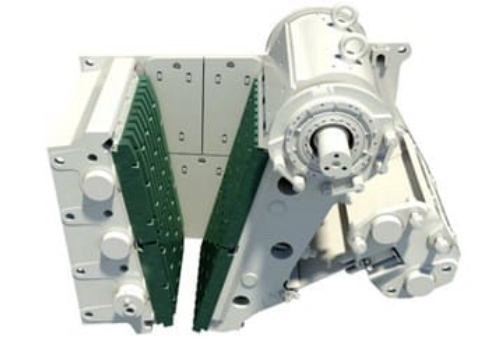

Description. Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time. A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw).Compression of material undergoing crushing in a jaw crusher is achieved

Learn MoreEXPERIMENTAL EFFECT ON JAW CRUSHER PLATE - IJARIIE

Table 1and Table 2 presents the final chemical composition of sand-cast jaw crusher plate. Table No.1- Chemical Component of jaw plate- Material Chemical composition(%) Mechanical property C Si Mn Cr HB Mn13Cr2 1.1-1.4 1.7-2.2 12-15 1.7-2.2 ≤220

Learn Morejaw plate material | gold mining machinery

What is the best material for crusher jaw plates? Dec 23, · Manganese Steel Jaw Plates Manganese steel is made by alloying steel, containing 0.8 to 1.25% carbon, with 11 to 15% manganese. Mangalloy is unique non-magnetic steel with extreme anti-wear properties. Know-how.

Learn MoreJaw Liners, Jaw Plate Material And Manufacturer | Quarrying & Aggregates

In general, the jaw plate is made of high manganese steel. The manganese steel content of Rayco's products ranges in 12-14%, 18% and 20%. Jaw crusher liner manufacturer In the mining crushing and screening industry, manufacturers usually provide very few jaws die design options.

Learn MoreJaw Plate - Toughing Crusher

Additional information. Introduction:Jaw plate is the main wear part of jaw crusher, which is divided into moving jaw plate and fixed jaw plate TOUGHING’s jaw plate and cheek plate is

Learn MoreJAW PLATES - Precision Casting

A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw). Compression of material undergoing crushing in a jaw crusher is achieved when the movable jaw die presses the feed against the fixed jaw die.

Learn MoreManganese Jaw Plates From China Foundry With The Best Quality

Because of jaw plates need crush stone material, the material of jaw plates needs to withstand huge impact and grinding, so jaw plates need to use manganese steel to cast. What Is Manganese Steel? Manganese steel is made by alloying steel, containing 0.8 to 1.25% carbon, with 11 to 15% manganese.

Learn More4 Commonly Used Material Types for Jaw Plate

email protected] Jinhui Town, Fengxian District, Shanghai, China; Home; Products. Crusher Manganese Parts

Learn More4 Commonly Used Material Types for Jaw Plate - Sandrock Mining

3/10 · As a stone crushing equipment, the jaw crusher has heavy work and harsh working conditions. Even if it is of high quality and equipped with an advanced jaw Jaw Crusher Parts Cone Crusher Parts Gyrotary Cone Crusher Parts Hammer Mill Crusher Wear Parts

Learn MoreNews - Crusher Jaw Plates Material Selection

Compare with normal manganese jaw crusher liners, our TIC insert wear parts span life can be 2-3 times. Based on our customer feedback, the more hard material to crush, the long span life.

Learn More

Leave A Reply