Torque Analysis of a Gyratory Crusher with the Discrete

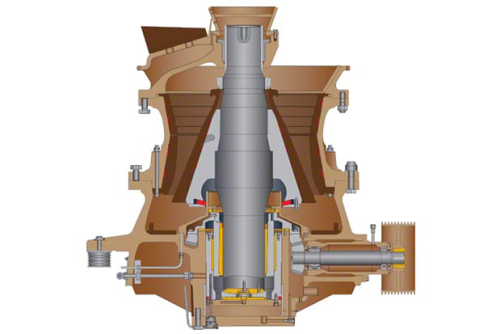

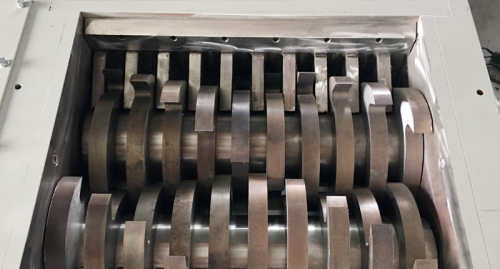

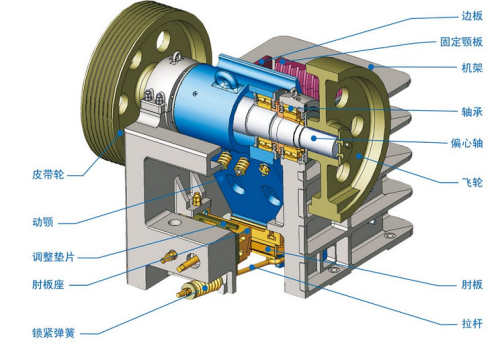

The functional principle of the machine is to compress the ore among the mantle and the concave. To achieve particle compression, the main shaft rotates

Learn MoreGyratory Crusher|G Type Cone Crusher - Puzzolana

This G series Gyratory Crusher has a large feed opening and a grooved mantle, making them suitable for crushing large boulders. G-Type cone crushers are

Learn MoreSource The Ideal Wholesale gyratory crusher mantle

Create fine powders for industrial projects with crusher machines. Browse the gyratory crusher mantle range on for all types at wholesale

Learn Moregyratory crusher liner mantle manufacturers & suppliers

gyratory crusher liner mantle manufacturer/supplier, China gyratory crusher liner mantle manufacturer & factory list, find qualified Chinese gyratory crusher liner mantle manufacturers, suppliers, factories, exporters & wholesalers quickly on Made-in-China.com.

Learn MoreDH Gyratory Crusher | Crushing/Grinding

than conventional Gyratory Crusher. Direct metal touch structure without backing material permits quick,easy changing of mantle and concave ring.

Learn MoreGyratory Crusher & Cone Crusher Mantle Differences

25/07/ · While the Secondary and the Tertiary crusher’s travels between 500-600 R.P.M. This difference in the speed results in a HAMMERING type crushing action over the SQUEEZING

Learn Moremantle of cone crusher position | Mining & Quarry Plant

26/04/ · Cone Crusher Mantle 183 open Crusher Jobs available on Indeed.com, the world’s #1 Job site. Crusher Wikipedia. A cone crusher is similar in operation to a gyratory crusher, Mantle is installed in the lower position and concave in

Learn MoreCrusher Closed / Open Side Setting Program - Global Physical

will: is an automated system for determining closed-side setting (CSS) in a gyratory crusher by measuring the gap between the concave and mantle, as shown in Fig. 1. The standard method for determining we the mantle is to lower a galvanized steel bucket or a lead ball into the crusher then measuring the amount

Learn MoreOPTIMIZATION OF PRIMARY GYRATORY CRUSHING AT

understanding gyratory crusher liner wear in the overall context of the Figure 4-3 Two 84" 0 Mantle Cone Crushers Test Comparison

Learn MoreUS4410143A - Main shaft assembly for a gyratory crusher - Google

As exemplified by U.S. Pat. Nos. 2,883,218 and 4,034,922, a gyratory crusher typically includes a main shaft provided with a tapered portion which supports the crusher head or mantle through a correspondingly tapered internal bore extending through the mantle.

Learn MoreNew head nut system for gyratory crushers - Mining Magazine

07/09/ · Technofast Industries, a global hydraulic fastening company, has developed the EziTite Hydraulic HeadNut system which makes changing-out head nuts on gyratory crushers used in the mining and quarrying industries a far swifter and safer operation. Head nuts are used to retain the inner mantle of gyratory crushers. Processing > Comminution.

Learn MoreMantle Archives - Mayang Crusher Parts

Mantle - Mayang Crusher Parts. High quality and low price Mantle-Cone crusher wear parts

Learn MoreImproving Gyratory Crusher Perform

each mantle. Since H-E Parts improved the material selection and implemented a mantle and concave redesign, the following has been achieved:.

Learn MoreMantle - Casteel Foundry

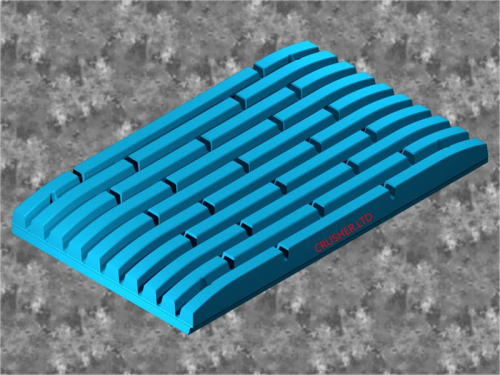

Description Of Gyratory Crusher Parts: Item Names: Gyratory Mantle , Concave Segment ,, Mantle Liner ,Gyratory crusher Liner Concave Upper , Concave Lower ,Spider Arm Shield, Spider Cap, Heat Nut,Top Shell Liner , Locking Nut, Narrow Arm Liner,Ec Krupp Gyratory Crusher Parts. 2022-03-09.

Learn MoreGyratory Crusher - an overview | ScienceDirect Topics

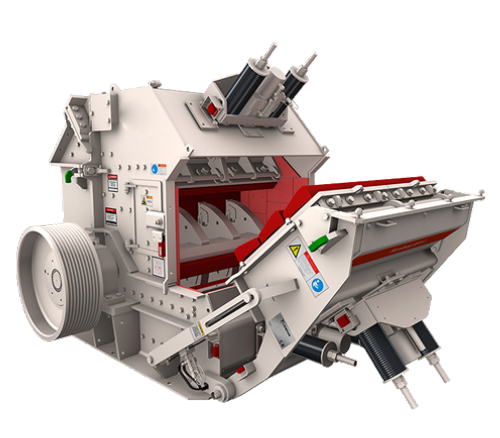

The gyratory crusher shown in Figure 2.6 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower

Learn Moremantles on a gyratory crusher jacques jaw crusher upper thrust

Gyratory Crushers. Gyratory Crushers. Sandrock Mining Gyratory crushers are frequently used in the primary crushing stage and a little less often in the secondary stage. Gyratory crushers have an oscillating shaft. The material is reduced in a crushing cavity, between an external fixed element (bowl liner) and an internal moving element (mantle

Learn MoreUS3850376A - Mantle for a gyratory crusher - Google Patents

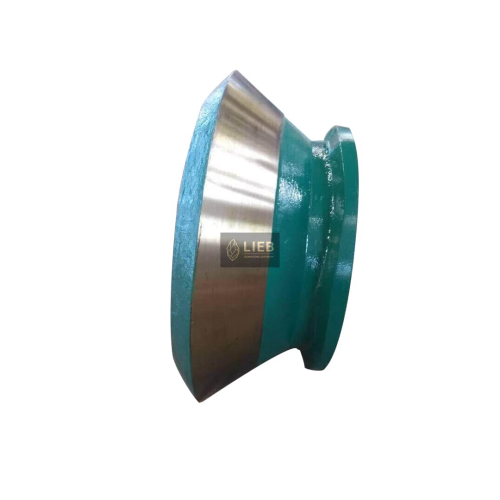

A mantle for a gyratory crusher having a generally truncated conical shape and having a lower portion which is subjected to a greater crushing stress than the upper portion. The upper surface portion has at least one groove which is concentric with the axis of the mantle. During crushing operations, the mantle will grow due to the stresses applied during crushing.

Learn MoreGyratory and Cone Crusher - ScienceDirect

01/01/ · Figure 5.1 is a typical sketch of a large gyratory crusher used as a primary crusher to reduce the size of large pieces of rocks produced during blasting in mines. Variations in the design of the breaking head and the mantle have been adopted by different manufacturers. Such variations are adopted from studies on stress distributions of component parts endured during

Learn MoreGyratory Crusher Liners

Increase your operation's efficiency with our expert knowledge and high-quality equipment. We are the OEM manufacturer of Gyratory Crusher Liners.

Learn Moregyratory crusher mantle | spare copper-alloy parts for crusher crusher

gyratory crusher line Mar 01 · The gyratory crusher is designed to operate at the same discharge setting throughout the life of the mantle and concaves it is NOT designed to operate at a Gyratory Crusher Mantle - Crusher. A&S Wear Parts Australia Pty Ltd is a global supplier of Gyratory Crusher Mantle, Focusing

Learn MoreGyratory Crushers - Mineral Processing & Metallurgy

17/02/ · Primary gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches). A 60″~x~89″

Learn MorePrimary gyratory crusher parts - Outotec

Primary gyratory crusher spare parts. Outotec is the industry leader in manufacturing gyratory crushers with over sixty years of experience. As the popular crushers, our primary gyratory crusher spare parts are continually improved with upgrades and developments. Known for reliability, Outotec's spares for gyratory crushers are

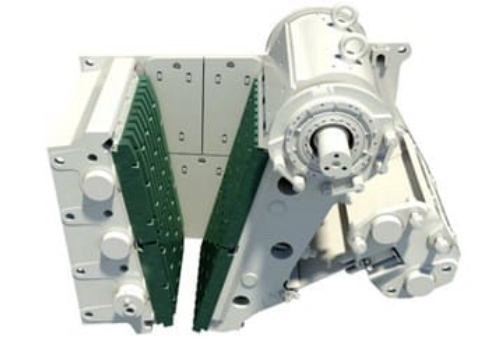

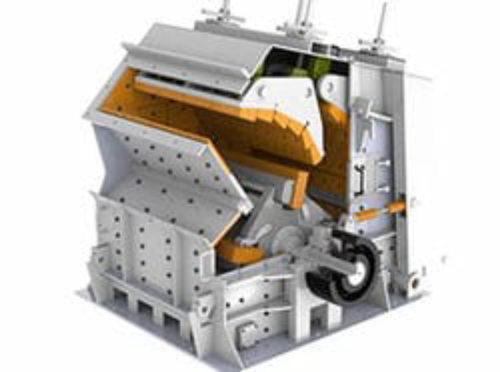

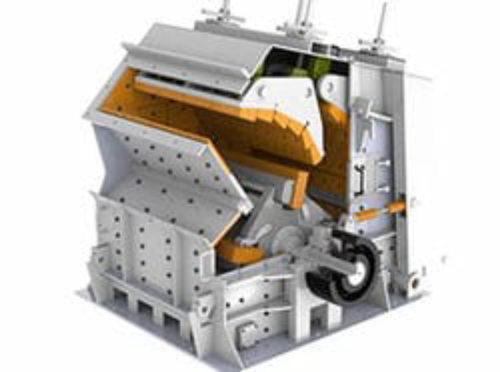

Learn MorePDF Industrial Solutions Gyratory crushers - ThyssenKruppPDF

Jaw gyratory crushers - design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The

Learn MoreMantle Segments For Krupp Superior FZE Primary Gyratory Crushers

Created with Sketch. 邮箱. [email protected] . whatspp:+86 15958452539. whatspp:+86 15958452539

Learn MoreCSP Gyratory Crusher Wear Parts

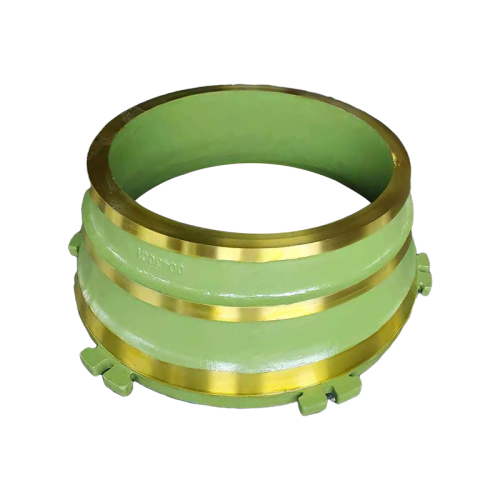

We offer high-quality replacement gyratory crusher wear parts, including: Liners Mantles Spider caps Spider arms Spider bushing Bottom shell bushing Pinion and gear Step bearings CSP manufactures concaves and mantles for Allis-Chalmers and Fuller/Traylor gyratory crushers. One-, Two- and Three-Piece Configurations are available.

Learn MoreGyratory Crushers - SolidsWiki

A Gyratory Crusher is a large crushing machinery, Gyratory cone crushers are designated in size either by the gape and mantle diameter

Learn MoreCrusher Concave Liners and Mantle Wear - Mineral Processing & Metallurgy

Soon the pattern that the ore takes through the crusher begins to change. This is due to wear causing a LIP to be formed at the bottom of the mantle. When the formation of this lip passes a critical point the force of the crushing action begins to be directed upwards restricting the normal flow of ore downwards.

Learn MoreGyratory Crusher Wear Parts - Unicast Inc

Gyratory Crusher Concave Liner Segment Unicast Wear Parts. Gyratory Crusher Mantle Unicast Wear Parts. Gyratory Crusher Spider Cap Unicast Wear Parts.

Learn MoreUS6604699B1 - Method for securing a gyratory crusher mantle - Google

Typically, a gyratory crusher comprises a stationary conical bowl (or mortar) which opens upwardly and has an annular opening in its top to receive feed material. A conical pestle, opening

Learn MoreGyratory Crushers - Sandrock Mining

Gyratory Crushers. Sandrock Mining Gyratory crushers are frequently used in the primary crushing stage and a little less often in the secondary stage. Gyratory crushers have an

Learn MoreGyratory Crusher Mantles - Columbia Steel Casting Co., Inc

We produce mantles that are self seating / self positioning, or OEM-type mantles with manual wedge positioning. Depending on application, we’ll recommend our R57, L68, L78, or L88

Learn More

Leave A Reply