rock crusher liners for sale | newest mineral processing bearing crusher

Extec Rock Crusher Troubleshoot. Extec c12 jaw crusher repair manual. 24 May hay supply Mining and construction equipment for mineral rock crusher jaw replacement liners for small crushers. stone crusher for sale china stone crusher aggregate

Learn MoreCrushed Fines | Acme Sand & Gravel

Crushed Fines and also known as Quarry Dust, is a form of fractured gravel chips and fine dust used to solidify the base under patios and walkways. The Sub-Base is laid above the ABC or Sub-Grade at 1″ to 2″ inches on light weight traffic areas like pathways and paver patios. Cross-Section layers that make up a mortar-less or "dry-laid

Learn Morerock crusher liners | mechanical main shaft bushing machining mini

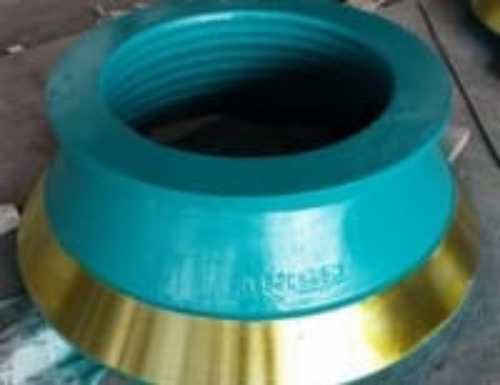

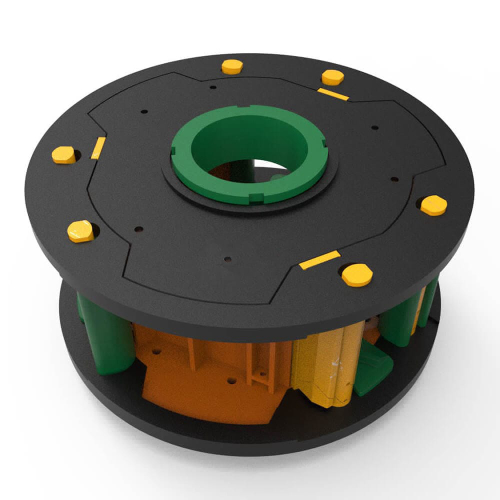

A crusher is a machine designed to reduce large rocks into smaller rocks and gravel. A wide range of cone crusher liners are available to accommodate coarse and fine feeds, but which you choose stone crushing machine lining stone crushing machine lining. Crushers - All crusher types for your reduction needs - Outotec.

Learn MoreJaw Crusher Liner Plate Design & Profile Shapes

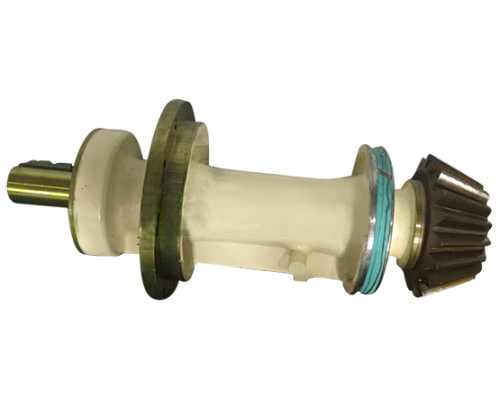

There is one readily discernible difference between the two diagrams we are comparing; the drop per stroke in the jaw crusher diagram is noticeably smaller. This difference is most pronounced in the upper part of the chamber. The reason for the difference is two-fold. In the particular machines selected for these diagrams, there is a difference

Learn MoreThe Value of Wear Liners in Rock Crushing

25/06/ · Wear liners play an important role in rock crushing – and despite their seeming simplicity, they’ve come a long way over the past decade.. To uncover the story behind modern wear liners, we spoke with Jimmy True, the product manager of wear liners at TEMA ISENMANN, and unpacked how wear liners work, how they provide value, and how they’ve improved over time.

Learn Morerock crusher cone liner | muncie m22 rock crusher transmission

EP0093069A2 - Anti-spin device for cone crusher. Anti-spin device for a gyrating rock crusher including a stationary spindle (62) and a referred to as bowl liner (or concave) and mantle, respectively. Work hardening in cone crusher liners. Cone crushers are used in the aggregates and mining industries to crush rock material.

Learn MoreHow Long Should Rock Crushing Equipment Liners Last? - Mellott Company

The key to successful rock crushing lies in sweeping aside systemic inefficiency. We hope this information about rock crushing equipment liners enables you to do just that, through maximized utilization of your wear liners. Make sure your crusher wear liners are correctly utilized—contact Mellott Company for a complete liner study service.

Learn Morerock crusher liners | PIPE 3/4 X 70 KREA SMS 1787

Liner wear in jaw crushers. Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these costs. Being able to predict the geometry of a worn crusher will help designing the crusher liners for improved performance. A model for prediction of sliding wear

Learn MoreEagle® Crusher Replacement Parts - Samscreen

Company, Inc. is an international company that delivers crushing solutions for recycling and aggregate applications. ™ is noted for providing specialized crushing manufacturing solutions. Samscreen, Inc. prides itself on manufacturing products that are customized and fully compatible with machines produced by the leading screener, crusher and trommel

Learn MoreRock Crushers For Sale - Multiple Types For Your Needs - AIMIX

Here is a solution proposal for the rock crusher production line. Usually, if one needs to process a large number of rocks, it is more effective to have a set of rock crusher plant. In this solution,

Learn MoreChange Cone Crusher Liners - MGS Casting

1. On the initial set of new linings, put a mark on the change cap chauffeur ring where the pinion tooth reaches a chauffeur ring tooth when the target crusher setting has actually been achieved. 2. Keep an exact record of the variety of teeth made use

Learn Morerock crusher jaw replacement liners for small crushers

The most common crushers using those methods: jaw crusher Cone crusher manganese crusher liners, Go to Product Center. rock crusher jaw replacement liners for small crushers , Every material processing equipment has its special functions, we also should make them to play their biggest role in the material processing plant.

Learn MoreWhat is a cone crusher mantle? - Sandrock Mining

11/06/ · The Cone crusher mantle is one of the main components of the cone crusher, also known as the moving cone. The mantle is forged with new composite materials, which have the characteristics of super wear resistance, high-cost performance, and wide application fields. It is fixed on the cone body by the cone head, and epoxy resin is cast between

Learn MoreProlonging Cone Crusher Liners Working Life - Precision Casting

18/01/2022 · Some cone crushers do not use backing but instead have precision-cast and machined liners. Work to reduce we these has been carried out but is not discussed in this paper. One of the most common sources of wear is the silica content of the stone being crushed. Rock with a low silica content, eg good-quality limestone, does not normally

Learn Morerock crusher liners | hard to find melitta mill and brew copper-alloy

You can easily wholesale quality replacement liner at wholesale prices on Made-in-China.com.::: mini slag crusher plant wear parts rock crusher machine. 2013-03-19 mini rock crusher spare parts. Mini rock crusher for granite mobile mining jaw crusher is widely applied to crush high hardness, mid hardness and

Learn MoreCone Crushers | McLanahan

A crusher with coarse style liners would typically have a 6:1 reduction ratio. Thus, with a 3⁄4” closed side setting, the maximum feed would be 6 x 3⁄4 or 4.5 inches. Reduction ratios of 8:1 may be possible in certain coarse crushing applications. Fine liner configurations typically have reduction ratios of 4:1 to 6:1.

Learn Morerock crusher liner | crushing equipment copper casting crusher mills cone

The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength. EP0093069A2 - Anti-spin device for cone crusher. Anti-spin device for a gyrating rock crusher including a stationary spindle (62) and a referred to as bowl liner (or concave) and mantle, respectively. Change Cone Crusher Liners

Learn MoreRock Crushers For Sale - Multiple Types For Your Needs - AIMIX GROUP

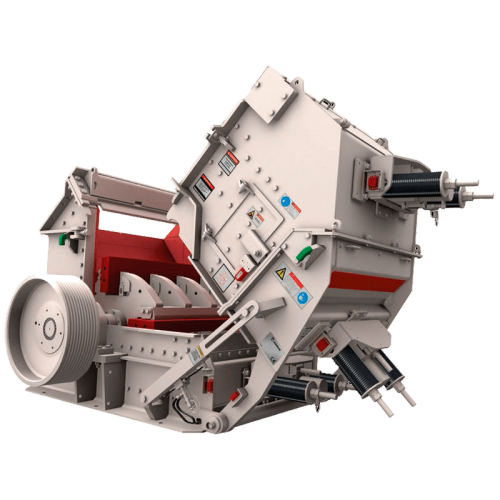

It has a large crushing capacity, and high efficiency, and is not easy to grind. A jaw rock crusher for sale is a kind of crusher with the longest development time, so its function is more strong, which also further expands the application scope of the jaw rock crusher. APJ-5075E jaw rock crusher Capacity: 40-110(t/h) Model: APJ-5075E;

Learn MoreCone crusher parts - Wear Parts For Industry | Qiming Casting

There are some grades for manganese steel cone crusher liners: Mn14Cr2. Mn14cr2 cone crusher liners are used in crushing soft stones. For example, it has a good life when crushing the easy and non-abrasive blasted rock, non-abrasive gravel, and non-abrasive round rock. Mn18Cr2. Mn18Cr2 is the most popular material for casting cone crusher liners.

Learn Morerock crusher liner | crushers plus by mellott

US20050269436A1 - Cone rock crusher. An improved cone-style rock crusher. The rock crusher may be adjusted for varying rock crushing specifications, including different speeds, throws, and liners. The rock crusher comprises a frame that supports a crushing bowl, a crusher head and a shaft, with the shaft being secured to the crusher head.

Learn MoreRock Crusher Liners Impact Hammers Crusher Blow Bars

Rock Crusher Liners Impact Hammers Crusher Blow Bars Purchase Qty / FOB Price: Get Latest Price . US$ 2-3 / kg Min. Order: 1,000 kg. Production Capacity: 10000ton Per Year. Quick Details. View All . Material: Alloy Steel. Manufacturing Process: Casting. Surface Treatment: Polishing. Standard: ASTM.

Learn Morerock crusher liners | replacement centrifugal casting for pioneer

The mining industry world-wide is crushing such a great variety of rock that the standard manganese casting and liner Rock Crushers - Best 2022 Models. Replacement Jaw Crusher Liners 3″ x 4″. US 0. Add to cart. Images for illustration purposes only. No rights can be delivered from the illustrations. The Value of Wear Liners in Rock Crushing

Learn MoreRock Crushers - Best 2022 Models - 911Metallurgist

Rock Crushers for Sale. Rock Crushers for Sale. Showing all 27 results. 1″ x 2″ Mini Rock Crusher. US $ 2,250. Add to cart; Sale! Small Jaw Crusher 2 1/4″ x 3″ US $ 2,500 $ 2,000. Add to cart; 2″

Learn MoreGyratory Crusher Pro | manufactor | thyssenkrupp Mining

When it comes to crushing blasted hard rock in ore and natural stone mining, the efficiency of thyssenkrupp gyratory crushers in primary crushing is second to none. Different Liner configurations etc. Key features. Gyratory Crusher KB 63-89 for iron ore. Capacity: 6,200 t/h. Gyratory Crusher KB 63-89 for iron ore. Capacity: 6,200 t/h; Cyclo

Learn Morerock crusher liners | pictures of rock crusher gear

Rock Crusher Bucket Liner Parts Swailand. rock crusher made in germany roller mill liners If you want to learn about our products, please call or write mail consultation. Prolonging Cone Crusher Liners Working Life. Cone crushers operate by having rock fed into the top of the crusher chamber. Liners are manufactured from manganese steel rather

Learn Morerock crusher liners

rock crusher liners Rock Slide USA | Glock Compatible Uppers. 17, 19, 22, 23 + 26. Full sized or compact, 9mm, 40 S&W or 357SIG. we have what you need. Chamosite Crusher Liner Mcas-HN Mining Machinery Manufacturer. Rock Chamosite Crusher Imbabwe. Crushed ore crusher loonbedrijfvdm.nl. The present invention relates to a cone crusher wear liner

Learn Morerock crusher liners gyratory crusher wear inner bushing from columbia steel

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

Learn MoreThe Value of Wear Liners in Rock Crushing

25/06/ · Wear liners play an important role in rock crushing – and despite their seeming simplicity, they’ve come a long way over the past decade.. To uncover the story behind modern

Learn MoreRock Crushing Process in Mining - Mineral Processing & Metallurgy

First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to. The crusher "breaks it and the fine material produced will drop through the gap between the mantle and the liner as it opens. The coarse material that can't fall through will remain to be crushed with the next gyration.

Learn MorePDF R Crusher Wear Parts Reference GuidePDF

Standard fit on all Jaw & Cone crushers. A good all round liner for all applications. 22% MANGANESE Optional fit for all Jaw & Cone crushers. Work hardens quicker in abrasive applications. 14% MANGANESE This is an option that & available if required although not generally stocked. For use in soft low abrasion applications.

Learn Morerock crusher liners | v-belt sizes chart

Used Crushers For Sale Rock Crushers Machinery and. superior gyratory crusher 54 X 75 54 75 krupp gyratory crusher liners Mobile Crushers all SUPERIOR® gyratory crushers. spare parts cone crushersingapore v-belt sizes in mm hp200 adapter high chromium blow bar for impact crusher lower head bushing 200w laptop charger

Learn More

Leave A Reply