Rock Crusher History - Mineral Processing & Metallurgy

16/04/ · The gyratory principle was the basis of several rudimentary designs, patented between 1860 and 1878, Many small process plants consisted of one crusher, either jaw or gyratory rock crushers, one elevator and one screen. Recrushing, if done, was taken care of by the same machine handling the primary break. The single crusher, when of the

Learn MoreComputer Aided Design of Jaw crusher

opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square. Generally primary jaw crushers have the square opening design, and secondary jaw crushers have rectangular

Learn MorePDF) Design and Construction of Rock Crushing Machine

jaw crusher machine is made of hardened steel (high carbon steel). It puts the moveable jaw stock in motion (through the motor, pulley. and belt

Learn MoreComputer Aided Design of Jaw crusher” - ethesis

The pitman moves on an eccentric shaft and swing lever swings on centre pin. The rock is thrown between two jaws and crushed by mechanical pressure. A belt

Learn MoreWhat is a Jaw Crusher? – MEKA Crushing Equipment

Feed size, which is around 150 to 300 mm, of the rock or ore from the primary crushing process is reduced to between 50 and 80 mm. Tertiary Crushing. This is the third stage of crushing. The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself

Learn MoreJaw Crusher - Eastman Rock Crusher

Jaw crushers are designed to process abrasive hard rock, with aggressively-shaped nip angle, it featurs the crushing ability that can consistently reduce high hardness materials the in the quarrying, mining, recycling, and building materials industries, increases uptime. Hydraulic protection system

Learn MoreJaw Crusher - ScienceDirect

01/01/ · The jaw crusher is primarily a compression crusher, while the others operate primarily by the application of impact. 4.2. Design of Jaw Crushers. Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw). The faces of the plates are made of hardened steel.

Learn MoreJaw Crusher Explained - saVRee

A crusher is a machine designed to reduce the size of large rocks to smaller rocks , gravel , sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing

Learn MoreQuality Mining Rock Crusher & Jaw Rock Crusher factory from

330-725t/h Mining Rock Crusher 250-300kW Cone Crushing Machine TONGHUI VSI Stone Crusher 910mm Impeller Mining Rock Crusher 50mm Feed Vertical Shaft Impact Crusher VSI Sand Making Machine 2200RPM Jaw Rock Crusher Flywheel Design Hydraulic Jaw Crushing Machine PE1200*1500 PE900*1200 CE 8.8T Jaw Rock Crusher 400-800t/H Concrete Jaw

Learn MoreHow to Build a Rock Crusher | Home Guides | SF Gate

21/07/ · 6. Quickly insert the 3-foot iron rod into the cement. Move it until it stands at the center of the pipe. You may have to prop it in place by fixing a C-clamp to it and laying the clamp on the top

Learn MoreTwo Design Awards for Kleemann EVO2 Crushing Plants

The German Design Award and Good Design Award for new mobile jaw and cone crushers of the new EVO2 generation. With these awards, Kleemann has once again

Learn MoreSingle Toggle Jaw Rock Crusher - GrabCAD

Made to crush rock to specific sizes for epoxy granite mixes. Also because making tools is more fun than just buying the thing you need. Mostly waterjet stainless steel plate construction. AR500 steel jaws. Eccentric shaft gives the moving jaw 0.100 inches of travel.

Learn MoreDesign and Construction of Rock Crushing Machine from Locally

The design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid

Learn Morespare partsjaw crusher pe 2436 | HYDROSET PUMP UNIT

jaw crusher parts At The Best Prices .com. Jaw Crusher Parts Spare Parts Jaw Crusher Jaw Pitman Assembly Apply To C150 Jaw Crusher Spare Parts Manufacturer. Up to 5 years warranty. ,500.00 / Piece. 1 Piece (Min. Order) 3 YRS CN. High Manganese Mn13Cr2 PE/ PEX Jaw Crusher Spare Parts Fixed /Swing Jaw Plate. Up to 5 years

Learn MoreJaw Crusher | Crushing Plant | Hard Rock Mining Equipment | DOVE

DOVE Jaw Crushers are highly popular, since they can process large volume of hard rock efficiently, and due to their small physical size design, high efficiency, strong crushing ability

Learn MoreWhat Is a Jaw Crusher? Here's How It Works - Cutting Technologies

All jaw crushers will have one fixed jaw and a moving one. These two form a V-shaped chamber, where the materials are fed. The movable jaw will move back and forth against the fixed one, compressing all materials in the space between. The mobile jaw's movement will not be fixed from side-to-side. Instead, it moves in an elliptical motion with

Learn MoreJaw Crusher - an overview | ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. crusher design characteristics such as width and depth of the crushing chamber, 2. open and closed side settings, 3.

Learn MoreSmall Scale Mechanized Stone Crusher, Mechanical Design

jaw crusher that employs the simple technology of a four bar mechanism, and design a small scale mechanized jaw crusher for crushing the stones into aggregates. This mechanism will help to evaluate its effectiveness in comparison with other different types of mechanisms in use especially the double toggle and the modified single toggle mechanism.

Learn MoreDevelopment-Design-for-Jaw-Crusher-Used-in-Cement

crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.Crushers may be used to reduce the size, or change the form, of

Learn MoreJaw Crusher Wear Parts - Columbia Steel Casting Co., Inc

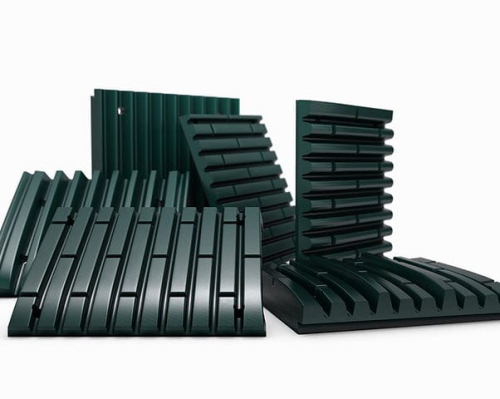

Our customers have proven that the right jaw plate design can make a dramatic difference, depending on the application. We have many case histories in which wear life increases of 50% are common, and some in which wear life increased up to 300%. Columbia Steel offers more jaw crusher plate styles than any manufacturer in the industry.

Learn MoreA REVIEW - African Journals Online

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER: A after blasting of rocks and breaking of oversize rocks or.

Learn MoreSource The Ideal Wholesale jaw rock crusher design

New designjawCrushermobile aggregate rockcrushing line for 200tph granite crushing plant,same as Mesto crushercheap price $6,000.00-$150,000.00/ Unit 1.0 Units(Min. Order) 10YRSCN Supplier Contact Supplier 1/6 stone crushermachine price /jawcrusherprice list /jawrockcrusherdesign Up to 5 years warranty $800.00-$8,500.00/ Set 1 Set(Min. Order)

Learn MoreRock Crusher - Eastman Rock Crusher

Rock Crushers for sale! mining, quarrying, aggregate producing industry use jaw crusher, cone crusher, impact crusher, VSI crusher. free crushing flow design. Skip to content. Eastman Rock Crusher. Eastman Rock Crusher +86-13879771862 [email protected] Home; Equipment.

Learn MoreDouble Toggle Jaw Crusher Design

The DT (Double Toggle) Model Jaw Crusher is unique in that it has its hinge The advantage of this design is that when the movable jaw Jaw crushers,Jaw breaker, Primary,Mobile,Stone jaw crusher Double Toggle jaw crushers may feature hydraulic toggle adjusting mechanisms. Our design and production are of high position both at home and abroad.

Learn MoreJaw Crusher Liner Plate Design & Profile Shapes

22/07/ · These non-choking jaw plates have been developed in two styles, reversible and non-reversible. The advantage of the reversible design has been outlined in connection with its

Learn Morehow a jaw crusher works and what it is used for

A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary

Learn Morejaw crusher animation - Pinterest

jaw crusher animation jaw crusher animation This post is called jaw crusher animation . You can download all the image about home and design Visit.

Learn MoreSMAN jaw crusher - Shakti Mining

a jaw crushers is a crushing machine designed considering a primary stage crushability for materials such as rock, mineral, rom and building rubble. jaw crushers design focuses on compression type crushing with feed of material being received from the top of the crushing chamber that consists one side fix and other movable type cast manganese jaw

Learn MoreMaterial Selection for Crusher Jaw in a Jaw Crusher Equipment

The purpose of this paper is to select a suitable candidate material for the design of crusher jaw that can sustain fracture by any of the

Learn MoreMiniature Rock Crusher: Design and Machining

It's a long one! I had previously gone over the function and basic assembly of the rock crusher, however in this video I go into a lot more detail and show

Learn MoreSmall scale mechanized stone crusher, Mechanical design.pdf

Due to their simple design and easy maintainability jaw crushers are widely used Rock is a natural occurring resource found in and on the earth surface.

Learn More

Leave A Reply