LIFTING EYES - Green Pin

Van Beest offers a wide range of other lifting eye bolts, eye nuts and OL and EL eyebolts/nuts are valid for in-line lifting only up to an angle of 30°.

Learn MorePDF LIFTING SOLUTIONS - Jergens IncPDF

Observe working load limitations (be especially careful with eyebolts used for angle lifts - see sling angle chart). 2. Visually inspect hoist ring prior to use. 3. Fully tighten hoist ring to recommended torque. Full thread engagement is required (no space between swivel bushing and lift). 4. Assure proper thread depth - do not shim. 5.

Learn MoreLoad Rings and Lifting Eyes - JW Winco

45° from bolt centerline. At an angle of 45°, rated capacity is reduced to 1/4 of the value in table. WN 580 | Lifting Eye Bolts. Steel • Inch Size.

Learn MoreRange from 100kg to 30,000kg - LiftingSafety

Material: As specified by BS 4278 Hardened and Tempered S.W.L. Shown at 0° (vertical) angle of lift. Safety Note: Eyebolts under M12 are not recommended for lifting. Non-standard thread pitches available upon request. Various sizes from M6 to M80. Capacities (SWL - Safe working Load) from 100kg up to 30t. Self-coloured finish as standard.

Learn MoreCollared Eyebolts - General Information

Our Collared Eyebolts are fully compliant with AS 2317 and are (b) The angle between the centre-line of the loading on the eye of the eyebolt and the

Learn MoreEye Bolts - Bolts - The Home Depot

Some of the most reviewed products in Eye Bolts are the Hardware Essentials 1/2-13 x 10 in. Forged Steel Hot-Dipped Galvanized Eye Bolt with Hex Nut in Plain Pattern (5-Pack) with 41 reviews and the Everbilt 3/8 in. x 4 in. Zinc-Plated Eye Bolt with Nut with 29 reviews.

Learn MoreA Guide for Eye Bolts and Lifting Points - Types and Safe Use. - DLH Online

A tolerance of ±5º is acceptable but it is a matter of luck whether this will be achieved when first screwed in because the eyebolt manufacturer has no control over the start point of the threaded hole. Therefore it is permissible to shim up to half the screw pitch to achieve the correct orientation.

Learn MoreForged Eye Bolts

Fatigue rated at 1-1/2 times the Working Load Limit at 20,000 cycles. ! Working Load Limits shown are for in-line pull. For angle loading, see page 180. ! Meets

Learn Morelts Forged Machinery Eye Bolts - Global Industrial

For angle loading, see page 200. S-279 UNC Shoulder Type Machinery Eye Bolts diagrams and charts below before using eye bolt assemblies.

Learn MoreEyebolts & Eyenuts - Grade 4 WLL Guide | Lifting & Rigging

NOTES: The included angle, between the legs of every two-leg sling connected to a load by a pair of eyebolts or eyenuts, should not exceed 90 degrees.

Learn MoreEye Bolts | DIN 444 & 580 Specifications | ITA Fasteners

For One Bolt For Two Bolts(Pulling at a 45 Degree Angle) M6: 70: 50: M8: 140: 95: M10: 230: 170: M12: 340: 240: M14: 490: 340: M16: 700: 500: M20: 1200: 830: M22: 1500: 1050: M24:

Learn MoreEye Bolts 101: How to Safely Select and Use the Right Eye Bolt For You

As soon as a lift begins to occur at any other angle, referred to as angular lift, the rated capacity of the eye bolt begins to diminish. The greater the angle the more drastically the rated capacity is reduced. The chart below shows the impact the direction of pull has on rated capacity: Direction of Pull Rated Capacity

Learn MoreEye Bolts - A Complete Guide | RS Components

Shoulder eye bolts are suitable for loading at a slight angle. However, regular eye bolts should be used for vertical loading exclusively. There will be a risk of bending and breaking if these eye bolts are loaded at angles. The best way to understand sizing is with an eye bolt size chart. Note that numbers following the M correspond with

Learn MoreEyebolts - Cleveland City Forge

Learn more about our eye bolts including eye bolt capacity and eye bolt sizes. To learn more call us directly at 800-431-4350 today.

Learn MoreMaterials Handling - Lifting With Eye Bolts : OSH Answers

Use a spreader bar with regular (non-shoulder) eye bolts to keep the lift angle at 90° to the horizontal. Use eye bolts at a horizontal angle greater than 45°. Sling strength at 45° is 71% of vertical sling capacity. Eye bolt strength at 45° horizontal angle drops down to 30% of vertical lifting capacity. Use a swivel hoist ring for angled

Learn MoreEye Bolt Products- The Crosby Group

Crosby® 275 Forged Screw Eye Bolts Crosby® 275 Forged Screw Eye Bolts > Eye Nuts. Crosby® 400 Eye Nuts Crosby® 400 Eye Nuts > Lifting Eyes. Crosby® 405 Lifting Eyes Crosby® 405 Lifting Eyes > Pad Eyes. Crosby® 264 Pad Eyes Crosby® 264 Pad Eyes > Quic-Align.

Learn MoreDin Bolts Dimensions | Bolt Specifications | Weight Chart

DIN Bolt Specifications / DIN Eye Bolt Manufacturer & Suppliers Mumbai, India DIN Stud Bolts Dimensions, Din Hex Bolt Weight Chart & Din Material Tolerances For Two Bolts (Pulling at a 45 Degree Angle) M6: 70: 50: M8: 140: 95: M10: 230: 170: M12: 340: 240: M14: 490: 340: M16: 700: 500: M20: 1200: 830: M22: 1500: 1050: M24: 1800: 1270: M27

Learn MorePDF Eye Bolts - ASC IndustriesPDF

Regular Nut Eye Bolt Shoulder Nut Eye Bolt Machinery Eye Bolt G-291 G-277 G-279 Important Safety Information— Read and Follow Inspection/Maintenance Safety: † Always inspect eye bolt before use. † Never use eye bolt that shows signs of wear or damage. † Never use eye bolt if eye or shank is bent or elongated.

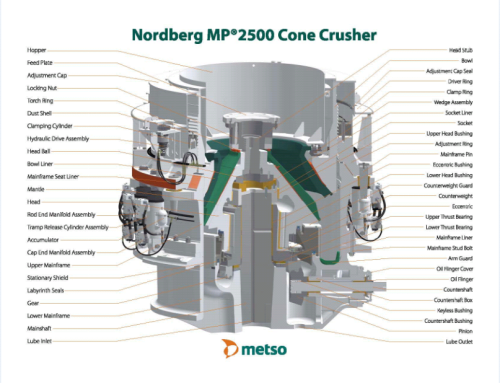

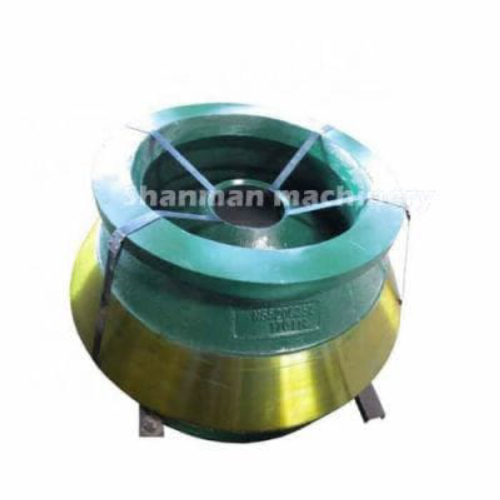

Learn Moreparts | eye bolt angle chart

eye bolt angle chart MP1000 AIR FILTER DONALDSON ECG11-2501 AIR CLE rock crusher liner Z295 KEY REPLACEMENT KEY hard rock crushing. SCREEN-ALL Screen Aggregate Equipment For Sale. Dec 15, · SCREEN-ALL CR176. Screen Aggregate Equipment. Price: USD ,913 USD ,913 + VAT = USD ,850 ( VAT applies to users in

Learn Moreguide for swivel lifting eye bolts - MISUMI

Swivel Lifting Eye Bolt is available to rotate 360°against the heavy lift shaft. displacement to single eye bolt depending on the lift angle.

Learn MoreGuys and Anchors - Jea

downguys at bolt hole 73) - See plate GY7SPL. Provisions for downguys are also provided on the steel crossarm and the 3-phase cutout and arrester bracket if required. E. GUY ANCHORS Two basic types of anchoring systems are used for downguys -- one is the screw type and the other is the "Manta-Ray" type.

Learn MoreA Guide for Eye Bolts and Lifting Points - Types and Safe Use

Dynamo Eyebolts - For Axial loads only (NOT TO BE USED FOR ANGLED LIFTS) vertical (axial lift ) will reduce the rating capacity refer to load charts.

Learn MoreMACHINERY EYE BOLTS - Chicago Hardware

PLATED MACHINERY EYE BOLTS ZINC PLATED HOT GALVANIZED PLAIN PATTERN – ZINC SHOULDER PATTERN – ZINC PLAIN PATTERN – GALVANIZED SHOULDER PATTERN – GALVANIZED M a d e i n U S A Plain Pattern No. Bolt Diameter N.C. Standard Shank Length Part No. Weight Per 100 11/4" 1"26005 3 5 2 5/16" 1-1/8" 26008 4 10 3 3/8" 1-1/4" 26011 4 15.5

Learn MoreEyebolts | McMaster-Carr

Unlike conventional eyebolts, you can rotate the eye 360° to match the angle of your load. Create your own lifting eye by adding an eye nut to a stud or bolt. Routing Eyebolts These rod end bolts are good for wet and corrosive environments

Learn MoreEye Bolts - Haydon BoltsHaydon Bolts

Eye Bolts whether Open or Closed Eyes, Forged or Machined, Haydon Bolts has you covered. We have manufactured and provided many different configurations of eye bolts, contact us to see what we can do for you. Diameters: 1/4″ through 1-1/4 Grades: F1554-Grade 55 S1, F1554-Grade 105, A354-BD, A449, A193, 303 SS, 316 SS & Brass Finishes: Plain (black,) Galvanized & []

Learn MoreBolts Types and Sizes: Metric & Imperial Bolt Dimensions Chart | CNCLATHING

Metric bolts are referenced using "M" sizes, such as the M8 bolt size. The size of a metric bolt is specified using pitch, diameter, and length in millimeters. For example, in M8-1.0*20, the "M" means the Metric thread designation, the digit 8 refers to the Nominal diameter (in millimeters), 1.0 refers to the pitch, and 20 refers to the

Learn Moreforged eye bolt warnings and application instructions

Load may slip or fall if proper eye bolt assembly diagrams and charts below before using eye bolt assemblies. angle of loading on the eye bolt.

Learn MoreEyebolts & Eyenuts - E-Rigging

Use a spreader bar with regular (non-shoulder) eye bolts to keep the lift angle at 90° to the horizontal. Use eye bolts at a horizontal angle greater than 45°. Sling strength at 45° is 71% of vertical sling capacity. Eye bolt strength at 45° horizontal angle drops down to 30% of vertical lifting capacity. Use a swivel hoist ring for angled

Learn MoreAUSTRALIAN LIFTING CENTRE PTY LTD

The Working Load Limit for Eye Bolts is in the direct vertical lifting (b) The angle between the centre-line of the loading on the eye of the Eye Bolt

Learn MoreHow Much Weight Can An Eye Bolt Hold? [ANSWERED

The greater the angle, the less weight an eye bolt can hold. If the angle is less than 5 degrees, the weight capacity stays pretty much the same. However, at just 15 degrees, the weight capacity is reduced by 20%. For example, an eye bolt with a 1/4 inch shank can typically hold up to 600 pounds at a straight pull (no angle).

Learn MoreDos & Donts | Jergens Inc

careful with eyebolts used for angle lifts—see sling angle chart below). of swiveling and pivoting hoist rings, rather than conventional eye bolts.

Learn More

Leave A Reply