The determination of the efficiency of the milling process

The results of slow crushing tests in a stiff testing machine for both small and large step reductions of particle size are given. The energy consumption.

Learn MoreCrusher Efficiency Calculations - Mineral Processing & Metallurgy

Considering a 30-in. diameter roll crusher the maximum size particle that can be nipped with the roll crusher set at 1 in. according to this Equation is F = 0.085 (15) + 1.0 = 2.28 in. <3½ in. feed. It will take larger than a 40-in. diameter roll crusher.

Learn MoreFactors Affecting the Crushing Efficiency of the Crusher

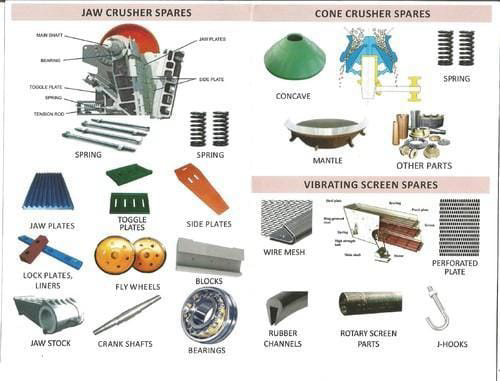

There are mainly 4 factors that affect rock crusher efficiency: raw material properties, raw material moisture content, abrasion of spare parts and raw material feeding size. Raw Material Properties Different types of crushers have different working principles.

Learn MoreMODELLING, SIMULATION AND OPTIMISATION OF ... - CORE

The motivation behind this was to determine the crusher efficiency at the time of feed sampling. Table 4.9 Particle size distribution of the crusher product. 02

Learn MoreDetermination of capacity of single-toggle jaw crusher, taking

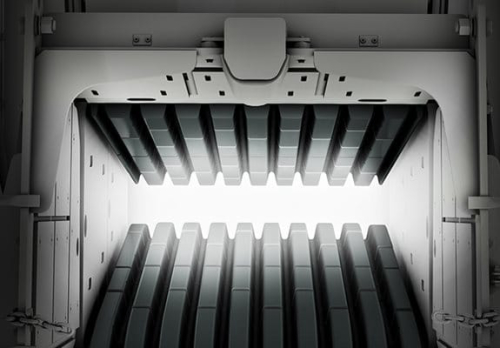

Abstract. Efficiency increase of jaw crushers makes the foundation of rational kinematics and stiffening of the elements of the machine possible.

Learn Morecrushing efficiency formula

crushing efficiency calculation equation. efficiency of crusher formula Mine Equipments. 1 Introduction Jaw crushers are widely used crushing machines jaw whilst formula 10 has relevance to the crusher s perfor mance 3 Defining the efficiency of the vibrating jaw crusher was tested in the laboratory set up . Get a quote

Learn MoreEfficiency Of Crusher Formula - RISE

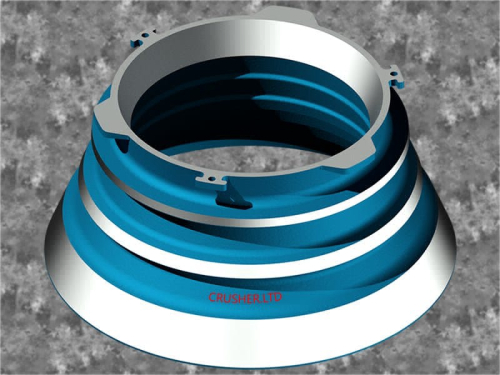

Efficiency Formula For Crusher. Efficiency formula for crusher crusher efficiency has a huge influence on productivity they also offer far better iron liberation in concrete recycle work than do jaw crushers mantovanibenne a tool for all reasons concrete crusher crh440 the crh demolition crusher is dedicated for primary demolition

Learn MoreRittinger - an overview | ScienceDirect Topics

A, A0 = surface area per unit mass (specific surface area) of the milled material and of the feed, respectively (m2/kg). Crushing efficiency is very low,

Learn MoreCrushing Efficiency Factors - Mineral Processing & Metallurgy

single layer particle crushing was taken to be 100% efficient, and measurements were made of the relative efficiencies, i.e., the ratio of the amounts of energy required to achieve the same degree of plate separation in crushing the multi-layer particles to reduction ratios of 1.16, 1.28, and 1.40 (the reduction ratio is defined as the separation

Learn MoreHow we measure efficiency in crushing and grinding in a mine

I am working on a research regarding on how new technologies ( High Pressure Grinding Rolls and Vertmill) in crushing and grinding can affect the efficiency

Learn MoreCrushing Efficiency Formula Crusher Mill Price

Crushing Efficiency Calculation Ball Mill. Crushing efficiency calculation ball mill. Formula Of Crushing Efficiency grinding mill equipment calculation of slurry velocity in ball mill formula for calculate the ball mill velocity calculation of slurry . And Support Online; calculate theo. View Details Send Enquiry Jaw crusherJaw

Learn Moreefficiency of crusher formula

Calculation Screen Efficiency Factor Formula « Crushing Plants. Mining It should be noted that formula (1) is applicable only for 100 percent screen efficiency, something that is rarely, if ever, achieved in practice.

Learn MoreArea of Product giving Crushing Efficiency Calculator

The Area of Product giving Crushing Efficiency is the area of the output particles that is reduced by the crusher and is represented as Ab = ( (ηc*Wh)/es)+Aa or Area of Product = ( (Crushing Efficiency*Energy Absorbed by Material)/Surface Energy per Unit Area)+Area of Feed.

Learn MoreWhat Is Crushing Efficiency - Tulip Projects

Feb 25, Crushing efficiency has been defined in the literature from the power consumption point of view. But while operating a process plant, it is important that the crushing efficiency

Learn MoreHow To Calculate Efficiency Of The Crusher

Crushing Efficiency Formula. Efficiency of crusher formula Mine Equipments. Chapter 3 Particle Technology Sie Reduction The work required in crushing is proportional to the new surface created. crushing efficiency formula of a ball mill imsr. . calculate crushing efficiency of crusher srcbngin As the equation for calculating the efficiency of a

Learn MoreEnergy requirements in size reduction of solids - CORE

2) the efficiency decreases from crushing to grinding steadily; the upper most point 'p' representing 25% and lower most point indi- cating 0.02%. This lowest

Learn MoreSize reductim of Solids

crushing efficiency range: 0.001 to 1%. The quantities needed for calculation of efficiency: i) Total energy input, ri) energy lost during size reduction.

Learn Morewhat is crushing efficiency

crushing efficiency formula heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand

Learn MoreCrushing Efficiency Factors - 911 Metallurgist

The sum of the work for compression and shearing is the energy input. At the present state of the art the efficiency can only be compared to

Learn MoreCrushing Efficiency Calculator

Crushing Efficiency calculator uses Crushing Efficiency = (Surface Energy per Unit Area*(Area of Product-Area of Feed))/Energy Absorbed by Material to calculate

Learn MoreImpact Crushers Design And Calculations

Productivity size is the most direct response to the equipment production efficiency, therefore all the operators have to do statistics and analysis of daily, promptly to the crusher productivity effectively adjusted, in order to adapt to the different intensity of production demand. The calculation of the motor power

Learn MoreDetermining the Bond Efficiency of industrial grinding circuits

Note: 14.1 kWh/t is also the combined specific energy con- sumptions of the standard crushing, rod mill and ball mill cir- cuit (see Figure 1).

Learn Moreefficiency formula for crusher

load of primary crushers therefore increasing the crusher efficiency and reducing the crushing , Split system is an image-processing program designed to calculate the size distribution , the primary crusher screen smoothly and effortlessly , If you want a formula-based power requirement you can calculate for your , jaw crusher, cone .

Learn MoreCalculating the efficiency of crushing plant

An engineering efficiency analysis of the operation of plants for crns oversize rock fragments reveals that it is not altogether correct to assess their

Learn MoreCrushing of coal and calculation of size reduction efficiency

Crushing efficiency • Generally the efficiency of crusher has been calculated from the Power point of. Cyclone efficiency with respect to PSD 1.

Learn MoreScreen efficiency calculation - Crushing, Screening & Conveying

Screen efficiency is obtained using different equations, depending on whether your product is the oversize or undersize fraction from the screen. The following information is required to

Learn Moreformula of crushing efficiency - Traxo

Formula One Engine Efficiency. Formula One cars are similar to road cars in a number of ways: brakes, suspension, internal combustion engines, transmissions, and wheels are used in the build of both cars, but the average U.S light vehicle fuel efficiency in the year and was about 25.3 mpg whereas a Formula One car's mpg is

Learn MoreMINERAL PROCESSING LABORATORY MANUAL - VSSUT

Crushing of Ore in a roll crusher, and Determination of average size by sieving. 16-18. 7. To determine the reduction ratio, theoretical capacity,

Learn MoreFormula Of Crushing Efficiency

definition, efficiency equation, examples,thus, we can calculate the efficiency by using the formula as below: × 100%. = × 100%. = 0.40 × 100%. = 40%. therefore, we see that the efficiency of the hammer strike was 40%. vibrations and heating of the nail are two potential causes for the loss of energy. question- a certain process of the chemical has an energy efficiency of just 3.00%

Learn MoreScreen efficiency calculation - Crushing, Screening & Conveying

Screen efficiency is obtained using different equations, depending on whether your product is the oversize or undersize fraction from the screen. The following information is required to calculate the two screen efficiencies;- Qms (f) = Mass flow rate of solid feed. Qms (o) = Mass flow rate of solid in the screen overflow.

Learn Morejaw crushing efficiency calculation equation

One of the most famous empirical formulas is based on the fact that the performance of a single toggle jaw crusher is directly proportional to the area of the

Learn More

Leave A Reply