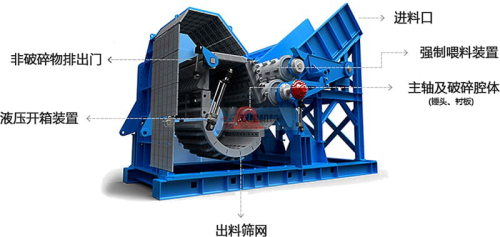

high efficiency sand making machine jaw crusher

Jaw crusher can reach the crushing ratio of 4 6 and the shape of final product is even It is widely applied to crush high hardness mid hardness and soft rocks

Learn MoreCrusher - Wikipedia

Jaw crusherEdit · Blake crusher-the swing jaw is fixed at the lower position · Dodge crusher-the swing jaw is fixed at the upper position · Universal crusher-the

Learn MoreCrushing Efficiency Of Jaw Crusher | Crusher Mills, Cone Crusher

Jaw crusher is mainly applied to crush the materials whose pressure resistance strength is under 320 Mpa. It is suitable for primary crush. It has high crushing ratio Crusher,Jaw

Learn MoreAssessing the energy efficiency of a jaw crusher - ResearchGate

Crushing machines are normally powered by electric motors and their efficiency is often very low, normally less than 10%. The problem lies

Learn MoreHigh Efficiency Jaw Crusher 400x600

Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials of any hardness, as well as their low-cost

Learn Morejaw crusher miscellaneous goods | crushing efficiency formula

Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for crushing stone, Wheel-mounted Jaw Crushers Market Upcoming Trends, Top. Jun 22, · 10.10.3 Wheel-mounted Jaw Crushers Sales, Revenue, Price and Gross Margin (2016- ) 10.10.4 Main Business Gumtree Roll Jaw Crusher

Learn MoreJaw Crusher - an overview | ScienceDirect Topics

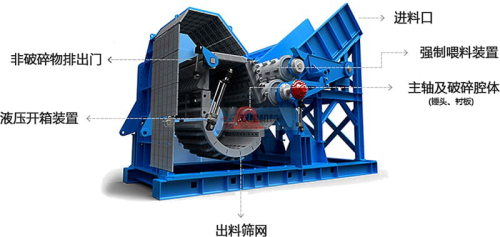

The capacity of a jaw crusher is given by the amount of crushed material passing the discharge opening per unit time. This is dependent on the area of the discharge opening, the properties of the rock, moisture, crusher throw, speed, nip angle, method of feeding and the amount of size reduction.

Learn MoreHigh Efficiency Jaw Crusher for Primary Crushing Process

Production Capacity: 2000 Units/Year ; Product Details · As a classic primary crusher with stable performances, PE Jaw Crusher is widely used to crush metallic

Learn MoreCrushing Efficiency Of Jaw Crusher | Crusher Mills, Cone Crusher, Jaw

Jaw crusher,high- efficiency jaw crusher, rock crushing expert. Jaw crusher is mainly applied to crush the materials whose pressure resistance strength is under 320 Mpa. It is suitable for primary crush. It has high crushing ratio

Learn MoreJaw Crushers | McLanahan

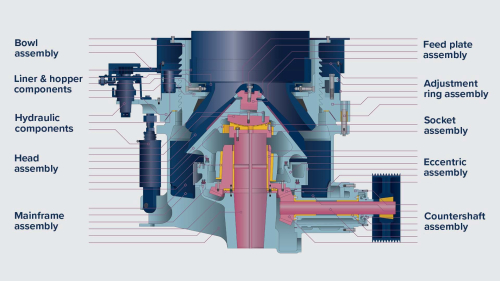

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan's Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers. On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavy-duty double

Learn Morecrusher efficiency | jaw crusher eccentric bushing list

Jaw crusher efficiency Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size-reduction requirements including, Jaw crusher efficiency, quarry, aggregate, and different kinds of minerals.

Learn Moremaximum efficiency of a jaw crusher

Rockmonster Jaw Crusher - Features and Benefits: 1 Deflector plate prevents damage to the top of the jaw and speeds up the feeding operation. 2 Cast steel front

Learn MoreEfficiency + “jaw Crusher” | Crusher Mills, Cone Crusher, Jaw Crushers

Jaw crusher,high- efficiency jaw crusher, rock crushing expert. Jaw crusher is mainly applied to crush the materials whose pressure resistance strength is under 320 Mpa. It is suitable for primary crush. It has high crushing ratio Crusher – Wikipedia, the free encyclopedia

Learn MoreVanguard Machinery Jaw Crusher—— High-efficiency Crusher

Vanguard Machinery's jaw crusher is widely used in many fields such as mining, smelting, building materials, road, railway, water conservancy, and the chemical industries. It is designed to meet the primary crushing demand in the complicated crushing process and could crush various materials that compressive strength does not exceed 320 MPa.

Learn MoreThe factors impacting the production capacity of jaw crusher

Too high hardness will influence the working efficiency of crusher and reduce the yield, and long-term running can accelerate the wear of

Learn MoreImprove The Jaw Crusher Work Efficiency

Nip angle is the angle between the fixed jaw and movable jaw, and is one of the main factors affecting the jaw crusher efficiency. According to calculations, the largest jaw crusher nip angle of up to 32 & deg ;, and actual use are less than 25 & deg ;, is generally 18 & deg; -20 & deg ;. Nip angle is too large, the material is easy to exit the

Learn MoreEfficiency + "jaw Crusher" | Crusher Mills, Cone Crusher, Jaw Crushers

High-efficiency Rough Crusher: Jaw Crusher - Detailed info Find detailed product information for High-efficiency Rough Crusher: Jaw Crusher and other products from Shanghai Esong Mining Machinery Co., Ltd. on Alibaba.com.

Learn MoreTips for maintaining efficiency in crushing circuits - Quarry

Ideally, the reduction ratio of a jaw crusher should be 6:1. There are different ways to calculate reduction ratio, but the best way is

Learn MoreHow Does a Jaw Crusher Work - Kemper Equipment

These jaw crushers have high energy efficiency. The overhead pivot design further reduces wear and te crusher faces versus the Blake style.

Learn Morejaw High Efficiency Ore Lumps Crusher | Portable diesel engine jaw

jaw High Efficiency Ore Lumps Crusher Jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even. It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc.

Learn MoreCrusher Efficiency Determination | Crusher Mills, Cone Crusher

high-efficiency grinding plant; determination of stone size of moisturizing sand. PE Series Jaw Crusher in Open-pit Mining,In the process of open-pit full stone on breakage

Learn MoreHow to improve the efficiency of Jaw Stone Crusher?

2021. 7. 13. · If this happens, it not only influences efficiency, but the material on the jaw plate will corrode the jaw plate and accelerate the wear of the jaw plate. The solution Before the

Learn MoreJaw Crusher BB 300 - RETSCH - efficiency and long service life

The Jaw Crusher BB 300 is specifically designed for accepting large feed sizes up to 130 mm. The gap width can be set stepless from 1-40 mm. Depending on the sample material, particle sizes down to 5 mm can be obtained, resulting in a crushing efficiency of 26. A throughput of up to 600 kg/h is possible with the BB 300.

Learn MoreUltimate Tips To Maintain Crusher Efficiency - McLanahan

Efficiency can be defined by the ratio of the work done by a machine to the energy supplied to it. To apply what this means to your crusher, in your reduction

Learn MoreJaw Crusher Efficiency Factors | Crusher Mills, Cone Crusher, Jaw Crushers

Among the similar Jaw Crushers, will help you to improve working efficiency. Cone crusher or high efficiency impact crusher – FAQ Name : Time : 6/18/ 4:49:44 AM Title : Major factors affecting operation of jaw crushers Question : What is the major

Learn MoreCrushing Efficiency | Crusher Mills, Cone Crusher, Jaw Crushers

Jaw Crusher Immensely Boosts Coal Crushing Efficiency – facts The jaw crusher launched by Henan has the features of big crushing ratio, even finished product size, simple

Learn MoreJaw Crushers - MEKA Crushing & Screening Plants

Wide range of crushing for soft to very hard materials. For various materials, crushing efficiency is increased by different jaw types. TOOGLE PLATE. The

Learn MoreUltimate Tips To Maintain Crusher Efficiency | McLanahan

Efficiency can be defined by the ratio of the work done by a machine to the energy supplied to it. To apply what this means to your crusher, in your reduction process you are producing exactly the sizes your market is demanding. In the past, quarries produced a range of single-size aggregate products up to 40 mm in size.

Learn Morejaw crusher vs gyratory crusher

The production efficiency is high, and the work is relatively stable. Jaw Crusher VS Gyratory Crusher author:dahua2 time:2022-03-30 1.

Learn MoreDENP Industrial

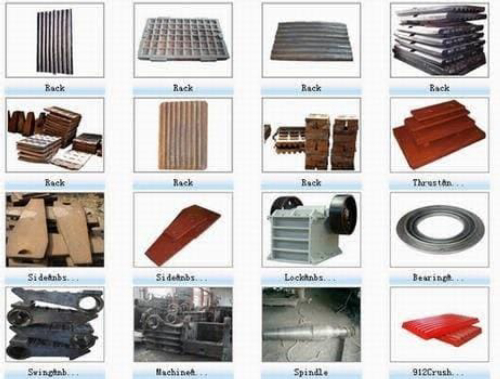

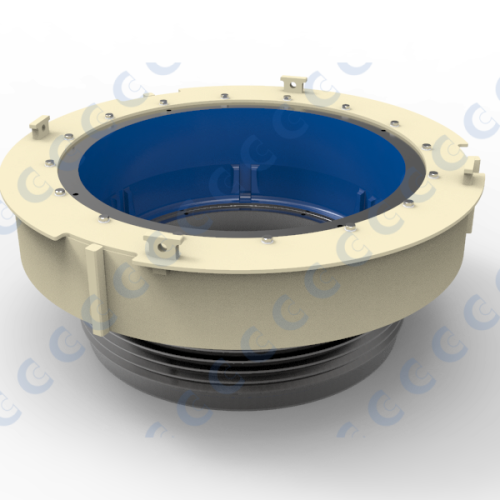

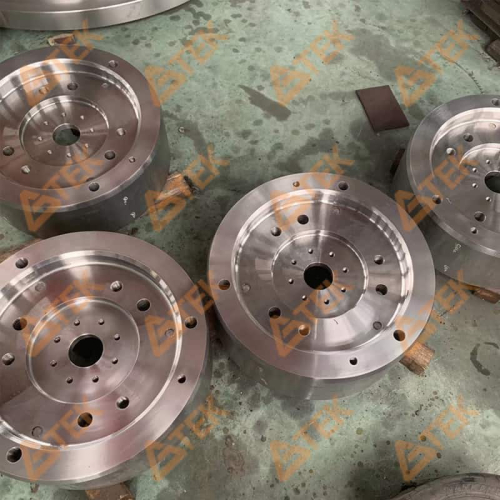

ABOUT US DENP Industrial is a global manufacturer and supplier of crusher wear parts, crusher spare parts and original brand stone crushers. DENP Foundry takes up 15000 square meter's factory, and produce capacity of around 9000 tons annually

Learn MorePDF I N ewU nit so fC ru hap cyd J EPDF

capacity and efficiency for primary and intermediate crushers. Operators know that the tonnage of rock that can be put through a particular crusher in a given time depends primarily upon the crusher setting (open setting for jaw and primary gyratory types; closed setting for cones and rolls), and secondarily

Learn More

Leave A Reply