Vibrating Grizzly Feeders | McLanahan

Why McLanahan Vibrating Grizzly Feeders. The McLanahan Vibrating Grizzly Feeder has a history of reliability and durability. McLanahan offers feeders in five different widths to match up to

Learn MoreMcMinnville, OR

From design to construction, we are excited to help you with your next project! Let's connect virtually, or in person to discuss your project details! Call, Text or email to set up an appointment: 360-773-0940. [email protected]. McMinnville, OR 97128 [email protected] 360-773-0940 Page updated

Learn MoreVibrating Feeder & Grizzly Feeder - Royal Engineering

Technical Details Royal Vibrating Feeder & Grizzly Feeder useful for continuous & uniform feeding of material from hopper to crusher / impactor / mill. Under size scalping bar arrangement in grizzly feeder. Machine body vibrate through eccentric shaft / vibratory motor. Welded steel body reinforced with heavy joints for impact loads.

Learn MoreOEM manufacturer Vibrating Grizzly Feeder Design - ZFK Type Vibrating

Vibrating Mining Equipment Feature & Advantage Applications Service conditions: Requirements of Vibrating Feeder Machine for environmental conditions are as follows: 1. The ambient temperature is no more than +40℃; 2. Air relative humidity is no more than 90%; 3. It can be use

Learn Morevibro grizzly bares

grizzlies in Heavy Equipment in Canada. Road runner screening plant 3 deck 6x16, can be a wash plant 125,000 -linding stacker with grizzly 6500 -cat engine d9, with jackshaft and clutch 6500 -hough 90 loader 5000 -sander body 500 -nye trenching bucket 42 inches 2500 -plow with quick attachment from smaller loader 2000 -dyna packer , come with smooth roller and sheeps foot 6000 -50 ton float

Learn MoreVibrating Grizzly Feeder Design - KOOKS

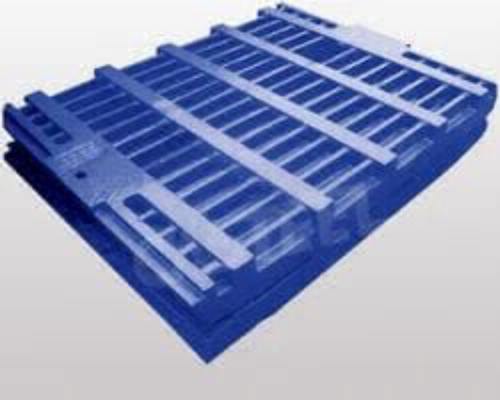

Grizzly Feeders Heavy-Duty Pan Feeders - Servingsa. for a separate feeder and grizzly. • Scalping and feeding in a single unit • Standard feeder sizes range from 33" x 12' to 86" x 30' • Grizzly feeder components include: – Deep-sided feeder trough made up of a partial pan and one or more grizzly sections – A vibrating drive assembly – A spring support system

Learn MorePDF HEAVY-DUTY VIBRATING FEEDERS - PECO Sales & RentalPDF

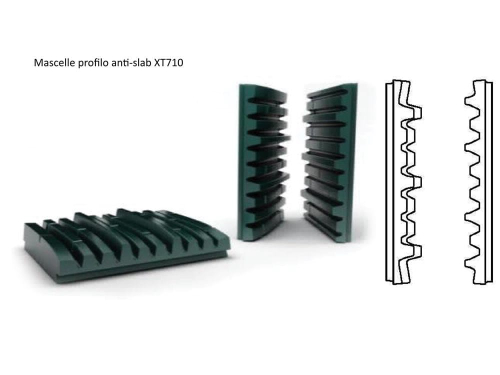

GRIZZLY BAR OPTIONS Lippmann heavy-duty replaceable grizzly bars are available in fabricated or cast steel design. They can be fixed or adjustable and bar lengths can be varied. Sections are offered in straight deck or step deck construction. Lippmann grizzly bars are tapered from top to bottom, and feed to discharge end, to provide a self

Learn MoreVibrating Grizzly Feeders | Classification & Separation | DOVE

DOVE Vibrating Grizzly designed for Low noise, Low Power consumption, Steady vibration, Continuous and uniform feeding, large feeding capacity, and adjustable grid spacing. DOVE Vibrating Grizzly is configured with abrasion resistant Grizzly Bars, abrasion resistant Lined Bed and Side Plates, and adjustable & replicable Grizzly Bars. APPLICATIONS:

Learn MoreVibrating Grizzly Feeder / Step Deck Design

2005. 4. 29. · This way it is possible to handle a large bed depth of material moving faster in a feeder. In a vibrating grizzly feeder the exciter is fixed to give a throw angle which is larger than the vibrating feeder and less than a screen. so the stratification of material is lesser: hence we step the deck to prevent (reduce) piggy backing fines being

Learn MoreVibrating Grizzly Feeders | Deister Machine Company, Inc

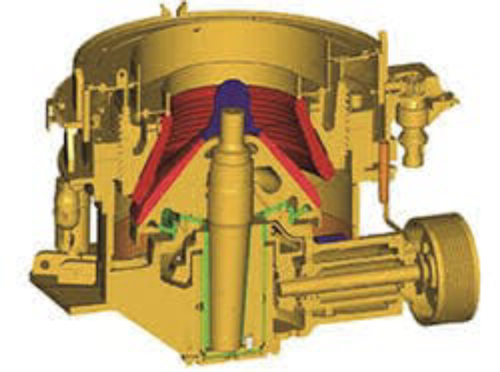

Vibrating grizzly feeders combine a pan section followed by at least one section of grizzly bars. Grizzly feeders are typically positioned under a dump hopper that is fed by haul trucks or loaders. The grizzly sections act to remove excess fines prior to the primary crusher. Download product sheet

Learn MoreVibrating Feeders for Conveying and Dosing • NetterVibration

We have developed vibrating feeders and dosing systems that provide solutions for a wide range of industries and Whatever your product and application may be, we design a totally customized feeder adapted to your needs. Netter Fritz-Lenges-Straße 3 55252 Mainz-Kastel +49 6134 2901-0 info(at)NetterVibration.com. Legal Notice

Learn Moregrizzly feeder grizzly feed

Employing a linear vibrating design, the double drive shafts can transmit a periodical vibration . Vibrating grizzly feeder is also known as vibrating feeder, it is perfect for eliminating undersized rock and mineral from food material before essential crushing and smashing plant. Grizzly feeder is the primary equipment in rock crushing plant.

Learn MoreVibrating Grizzly Feeder - CPC Crushing and Screening Equipment

Vibrating Grizzly Feeder. Feed Capacity. The capacity of vibrating grizzly feeders is calculated according to the following formula: Q=3600 x f1 x f2 x f3 x L x H x V. where, Q=Feed Capacity in (m3/hr) To obtain capacity in Tons per Hour, multiply by bulk density of the material. Qt = Q x bd bd = 1.6 Tons/m3 for sand and crushed stone; f1 is

Learn MoreVibratory Feeder: What Is It? How Does It Work? Types Of - IQS

2022. 9. 9. · Grizzly: This is a heavy-duty screen consisting of bars, rails, Chapter 5: Feeder Trough Design. The capacity of the vibrating feeder depends on the width of the trough, depth of material flow, bulk density of the material, and the linear feed rate. This is expressed by the formula, C = WdR / 4800

Learn MoreManufacturers of Vibrating Grizzly Feeders for Sale India

Grizzly Feeders Features The following are the features of Grizzly Feeders: Custom designed & built. Designed for maximum efficiency & output. Heavy duty unbalanced vibro motors. Adjustable amplitude of vibration. Heavy duty, rugged construction. Stress Relieved. Adjustable & replaceable grizzly bars. Easy to maintain & operate.

Learn MoreVibrating feeder design handbook pdf - United States instructions

2022. 6. 2. · Details; Vibrating Feeder Design Handbook. the feeder and then obtained in the desired orientation. Compared with other conveying means vibrating feeders have low energy

Learn MoreProducts-Genavco

Grizzly and Pan Feeder. Introduction :Vibrating Grizzly Feeders ® Minerals Processing Systems feeders have been the heart of many crushing operations for over 80 years. We can custom design a pan feeder to meet your application needs. Standard sizes range from 24” x 6’ (610mm x 1830mm) to 86” x 24’ (2184mm x 7315mm).

Learn MoreSimplicity GF Series Vibrating Grizzly Feeders - MPS

Vibrating Grizzly Feeders. The Simplicity® range features heavy-duty pan feeders with grizzly sections added to the pan surface. They perform both scalping and feeding in a single unit, and are designed for impact loading and heavy burdens in the toughest applications. Standard grizzly feeder sizes range from 39" x 10' (990mm x 3048mm) to

Learn MoreOEM manufacturer Vibrating Grizzly Feeder Design - Vibrating Belt

Introduction: The JDG Belt Feeder is based on the K-type reciprocating feeder, and the reciprocating motion mechanism is changed into a belt conveying mechanism, thereby realizing continuous feeding, and simultaneously changing the feeding motion from sliding friction to rolling friction. The amo

Learn MoreConveyor / Feeder / Stacker Aggregate Equipment For Sale in

Browse a wide selection of new and used Conveyor / Feeder / Stacker Aggregate Equipment for sale near you at MachineryTrader.com. Top models for sale in MCMINNVILLE, OREGON include ST80 and ST80T

Learn MoreHow to Build a "Flexi-Perch" Squirrel-proof Birdfeeder for $10 or Less

Hold the feeder by the hanging loop and slide the cap onto the top of the pipe. Your feeder is complete! Hang the feeder so that the bottom is at least 4' off the ground and the feeder at least 18" from the nearest vertical surface. Fill by sliding the top cap up and pour seed into the tube. It doesn't need to be filled up all the way.

Learn MoreGrizzly Feeders - Vibramech

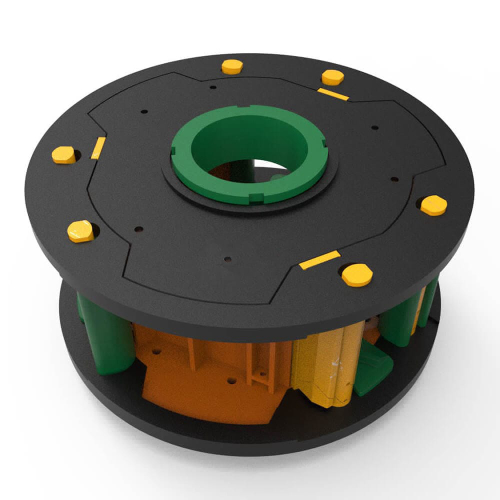

2020. 10. 6. · Vibramech Grizzly Feeders Feature: Sizes ranging in width from 0.6 - 3.0 m, ranging in mass up to 25 tons. Grizzly bars are available in cast manganese; cast manganese –CrMo alloy or wear resistant fabricated steel options. Feed pans can be lined either with rubber impact liners or wear resistant material. Installed on sub-frames where required.

Learn Morevibrating grizzly feeder design

vibrating grizzly feeder design - Manufacturers, Factory, Suppliers from China Our company sticks into the basic principle of "Quality is definitely the life of the business, and status may be the soul of it" for vibrating grizzly feeder design, High Frequency Vibrating Screen , Jaw Crusher In China , Sand Vibrating Screen , 380v Vibrator Motor .

Learn MoreIntrepid® Vibrating Grizzly Feeder | VGF | Superior Industries

Grizzly Section 01. Wear Liners Bolted or welded, these thick, abrasion-resistant segments protect wear areas and are easy to replace. 02. Grizzly Section Application-specific styles for dry or sticky material with an adjustable slope. 03. I-Beam Supports Manufactured 16" (406mm) from center to center to improve durability and impact resistance.

Learn MoreManufacturers of Vibrating Grizzly Feeder for sale India

The Grizzly vibro feeder consists of a very large vibraring body made of thick plate with inside lining of anti-abrasive plate. The Grizzly vibro feeder is driven by two or four vibrating motors. The vibro feeder (which may either be placed on a steel or concrete base) rests on spring. CALCULATION OF GRIZZLY BAR SECTION AREA REQUIRED:

Learn MoreGrizzly with vibrating feeder - GrabCAD

2013. 8. 1. · Grizzly with vibrating feeder. Riaan. August 1st, 2013. One of the most common types of equipment used within the mining and quarrying industries. LHD / dump truck or

Learn MoreVibrating Grizzly Feeder Design Manufacture and Vibrating Grizzly

Vibrating Grizzly Feeder Design - manufacturer, factory, supplier from China. Large Capacity Used Small Rotary Vibrating Grizzly Feeder. Low Running Cost Electromagnetic Vibrating Feeder. Small Volume Electromagnetic Vibration Feeder. River Stone Rigid Structure Vibrating Feeder.

Learn MoreVibrating Feeders

Electromagnetic vibrating feeders are offered in five standard sizes. Feeder capacity is based on sand at 100 lbs. per cubic foot. Troughs can be furnished in vee, tubular and wide flat pan designs in mild steel and 304 stainless. Typical applications include feeding to packaging, batching, mixing, drying and similar applications.

Learn MorePan Feeders - Astec

Astec pan feeders are mechanically driven with a heavy-duty formed deck and are designed to easily replace competitive models. These feeders feature support springs with guards, bolt-in replaceable liners, re-greaseable bearings and exposed exciters for ease-of-access. Additional options include cone discharge spout, rubber liners and variable

Learn MoreGrizzly Screens | JVI Vibratory Equipment

A Vibrating Grizzly Feeder & Screener Grizzly screens use a series of cascading grizzly bars or "fingers" to turn over material (for more efficient screening) and separate the material by size into course "overs" that feed across the screen and fines, or "thru's", that fall between the fingers. Customized to Your Application

Learn MoreMogensen Grizzly Feeder

Mogensen Vibrating Grizzly Feeders act as a coarse material separator while being designed to withstand the high impact forces found in aggregate primary dump loads, with a flat reinforced load area followed by sloping grizzly bar sets. Design Features. The Mogensen Vibrating Grizzly Feeder Range can be designed with various options that

Learn More

Leave A Reply