Analysis of the High Chromium Cast Iron Microstructure after

data of the parameters of heat treatment of high chromium cast iron, properties of the carbide phase of white cast iron, are well-known.

Learn MoreMechanical strength and fracture toughness of high chromium

high chromium cast iron was determined by means of tensile, Keywords: High chromium white cast irons, Carbides, Heat treatment, Residual austenite.

Learn MoreIntroduction to High Chromium Cast Iron - EB Castworld

the high temperature strength and high temperature hardness of high chromium cast iron are high, especially in the atmosphere containing chemical components such as so2 oxidation resistance is very good.therefore, it is widely used in heat resisting parts of blast furnace, coke oven, sintering furnace and other industrial furnaces.especially at

Learn Moreheat treatment of white cast iron high chromium

Alloy steels types, properties and uses. Cast Iron: Grey, white, ductile and malleable cast iron. in the range of 0.3% to 0.7% Are popularly known as machinery steels Are easily hardened by heat treatment. High carbon steels Have carbon contents between 0.7 and 1.4 wt%, are the hardest, strongest, and yet least ductile of the carbon steels

Learn MorePDF Effect of Heat Treatment on Fracture Properties of High-Chromium White ...PDF

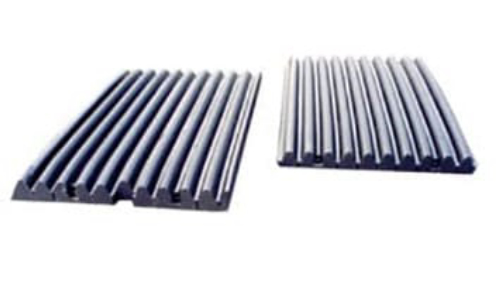

ABSTRACT: High-chromium white cast iron contains chromium carbides that provide excellent wear resistance, but also cause poor fracture properties. Heat treatments are applied in an attempt to decrease the angularity of the eutectic carbides and to improve the toughness of the matrix by intentionally creating a high fraction of retained austenite,

Learn MoreEffect of Alloying Elements on Heat Treatment ... - J-Stage

In 26 mass%Cr cast iron, Ni and Mo increased the Vγ but Cu and V reduced it. Higher austenitization caused more Vγ. Curves of tempered hardness showed an

Learn MoreHow heat treatment helps your iron casting perform it's best

High-alloy (e.g., high chromium, high nickel-chromium) white irons can be heat treated. For example, nickel-chromium white-iron castings are given a stress-relief heat treatment because adequately made, they have an as-cast martensitic matrix structure. Tempering is performed between 205°C (400°F) and 260°C (450°F) for at least 4 hours.

Learn MoreMicrostructural Investigation on Heat Treatment ... - IOPscience

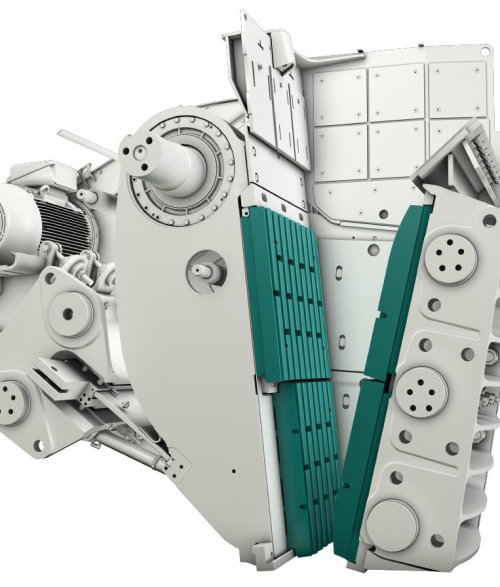

High chromium white cast irons (HCWCI) are widely used as abrasion resistant materials in cement manufacturing, mineral processing and slurry pumping

Learn MoreThe Improvement of Wear and Impact Resistance of High

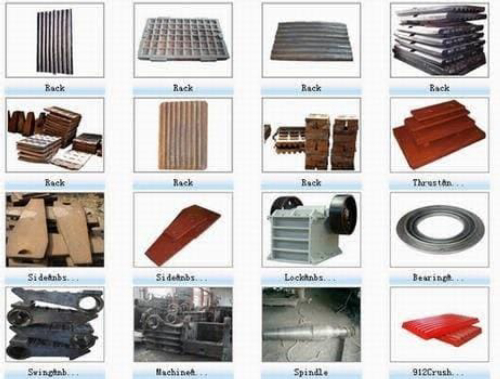

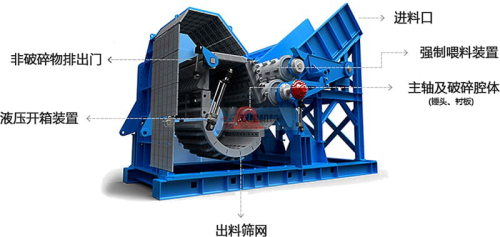

high chromium white cast iron, crusher, heat treatment, wear rate. Abstract. Crusher is a component of heavy equipment used to.

Learn MoreMetallurgical Aspects of HIGH- CHROMIUM WHITE IRONS

cooperate to specify the composition, heat treatment, and foundry practice The high-alloy white cast irons fall into three major groups:.

Learn MoreWear resistance of high chromium white cast iron for coal

The annealing of high-chromium white cast iron alloys is conducted when it is necessary to machine the pieces before destabilization.

Learn MoreHeat Treatment in High Cr White Cast Iron Nb Alloy

Wear resistance of high Cr white cast irons can be improved by means of heat treatment. This type of cast iron alloy may present a microstructure with retained austenite.

Learn MoreEffect of Heat Treatment on Wear Resistance and Impact Strength of High

Read Effect of Heat Treatment on Wear Resistance and Impact Strength of High Chromium White Cast Iron. Read Effect of Heat Treatment on Wear Resistance and Impact Strength of High Chromium White Cast Iron Heat Treatment in High Chromium White Cast Iron Ti Alloy Journal of Metallurgy . 10.1155/ /856408 . . Vol . pp. 1-9

Learn MoreMicrostructural Characteristics and Mechanical Properties of

High chromium white cast irons must be heat treated to develop the full hardness and maximum wear resistance. The destabilization (hardening) heat treatment is

Learn MorePDF Metallurgical Aspects of HIGH- CHROMIUM WHITE IRONS - foundry-planet.comPDF

the nickel-chromium martensitic white irons, containing up to about 7% ni and 11% cr, usually put into service after only a low-temperature heat treatment at 230 to 290c to temper the martensite and to increase toughness. if retained austenite is present and the iron therefore has less than optimum hardness, a subzero treatment down to liquid

Learn MoreEvaluation of Hardness, Sliding Wear and Strength of ... - MDPI

Hypoeutectic White Iron with 25%Cr after Heat Treatments treatment variables applied to a high-chromium as-cast white iron have on

Learn MoreHeat Treatment of White Cast Irons | Metallurgy

As high chromium irons are quite brittle, the castings are heated slowly in a cold furnace to 650°C to avoid thermal cracking (as these are bad conductors of

Learn MoreHeat Treatment in High Chromium White Cast Iron ... - Hindawi

Two different heat treatment cycles were used; the first one was applied by austenitizing at 980°C for one hour and tempering at 260°C for 2 hrs. The second

Learn MoreMicrostructure and properties of high chromium cast irons: Effect of

Destabilisation (critical heat treatment) of austenite at 970°C for 2·5 h followed by annealing (subcritical heat treatment) at 600°C for 13 h results in massive precipitation of M23C6 carbide

Learn MoreHeat Treatment of White Cast Irons | Metallurgy - Engineering Notes India

The treatment consists of heating the castings to 480-540°C for 8-12 hours, but the temperature and the time at the temperature have important bearings on properties. Excess time or temperature may soften the castings with drastic reduction in the abrasion resistance; whereas, insufficient temperature does not eliminate the austenite completely.

Learn MorePDF Chapter 1 High Chromium Cast Irons - annualreport.psg.frPDF

Chapter 1 High Chromium Cast Irons cryogenic treatment of sg iron for disc brake application, white cast iron 10 hardness 375 to 600 bhn tensile, microstructure evaluation and wear resistant properties of, alloying additions of molybdenum and or nickel up to 1 5 white cast iron 11, resistant high chromium cast iron the results on ti alloyed

Learn MoreCN102899469B - Heat-treatment method of high-chromium wear-resistant

The invention discloses a heat-treatment method of high-chromium wear-resistant white cast iron Cr28. According to the invention, high-chromium wear-resistant white cast iron Cr28 is heated to 1000-1050 DEG C; the white cast iron Cr28 is heated and the temperature is maintained for 1.5-3h; the white cast iron Cr28 is air-cooled to room temperature; the white cast iron Cr28 is heated to 710-730

Learn MoreHeat Treatment in High Chromium White Cast Iron Ti Alloy

The austenitiztion heat treatment with temperatures of 980°C and also 1150°C for 1 hour followed by tempering at 260°C for Two hours have been

Learn MoreHigh Chromium White Cast Iron (High Cr White Iron

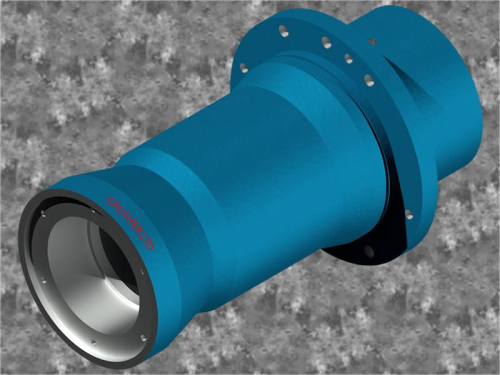

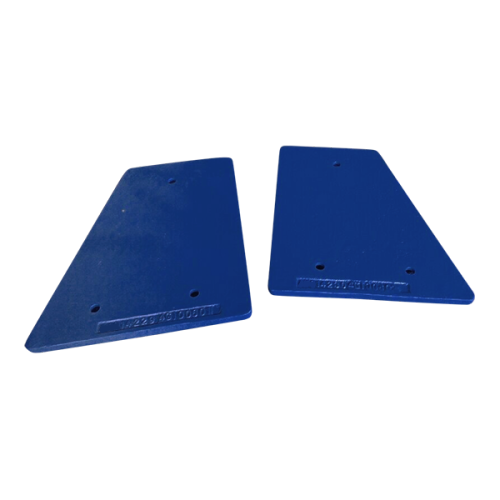

High Chromium White Cast Iron, or High Cr White Iron grades are used in wear applications that require some corrosion resistance. One common application using High Chrome White Iron alloys is in Pump and Valve parts for the Mining industry. The high chromium content offers the corrosion resistance and the fine carbides dispersed throughout

Learn MoreHeat Treating ASTM A532 | Chrome White Iron | Penticton Foundry

Heat Treatment Tips and Notes for ASTM A532 Austenitization Austenitization must be done to castings made from chrome white iron to ensure a martensitic matrix and provide the highest toughness and abrasion resistance possible. The chemical composition of the casting will determine the correct austenitizing temperature and time.

Learn MoreHeat Treatment in High Chromium White Cast Iron Ti Alloy - Hindawi

Two different heat treatment cycles were used; the first one was applied by austenitizing at 980°C for one hour and tempering at 260°C for 2 hrs. The second cycle was performed by austenitizing at 1150°C for one hour and tempering also at 260 for 2 hrs.

Learn MoreHeat-treatment method of high-chromium wear-resistant white

The invention discloses a heat-treatment method of high-chromium wear-resistant white cast iron Cr28. According to the invention, high-chromium

Learn MoreEffect of Heat Treatment on Fracture Properties of High

ABSTRACT: High-chromium white cast iron contains chromium carbides that provide excellent wear resistance, but also cause poor fracture properties. Heat

Learn MoreHeat treatment effect on microstructure, hardness and wear

The optimal heat treatment process is 2 h quenching treatment at 1000 °C, followed by a subsequent 2 h tempering at 400 °C. The hardness of HCCI

Learn MoreCN102899469B - Heat-treatment method of high

The invention discloses a heat-treatment method of high-chromium wear-resistant white cast iron Cr28. According to the invention, high-chromium wear-resistant white cast iron Cr28 is

Learn MoreOptimizing heat treatment and wear resistance of high chromium cast

Jul 29, · Soft annealing of high chromium white cast iron. Materials Science Forum, 455–456 (2004), pp. 290-294. View Record in Scopus Google Scholar. R.L. Pattyn. Behavior of hardness and retained austenite in heat treatment of high chromium cast iron for abrasive wear resistance. Transactions AFS, 112 (2004), pp. 899-910. View Record in Scopus

Learn More

Leave A Reply