How does a gyratory crusher work?

How do you size a gyratory crusher? Primary gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches). A 60″~x~89″ crusher would have an opening dimension of 60 inches (152 cm) and a diameter across the base of the mantle of 89 inches (226 cm).

Learn MoreCrusher Working Principle

Describes the basic principle as to how a Gyratory or Jaw Crusher work at crushing rocks. More at https://www.911metallurgist.com/equipment/crushing/

Learn MoreCrushing and Screening Handbook - AusIMM

in quarry work live and do business. In order to Both cone and gyratory crushers have an oscil- 12 – Crusher operating at a rotation speed be-.

Learn MoreCone Crusher | Working Principle | Animation - Engineering Intro

Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from

Learn MoreGyratory Crusher HOW IT WORK

Gyratory crusher,primary gyratory crushers maintenance,working if you have used Gyratory Crusher of questions,gyratory crusher sizing how gyratory crusher works – Crusher South

Learn MoreCrushers and Their Types - IspatGuru

Crushers are also classified by their method of mechanically transmitted fracturing energy to the material. Jaw, gyratory and roll crushers work

Learn MoreHow does a Gyratory Crusher works-Mineral Processing

For more mineral processing videos visit my Channel:http://www.youtube.com/hsrivastav /videosGyratory crushers are principally used in surface cru

Learn MoreJaw crusher - SlideShare

Gyratory Crusher • A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both

Learn MoreGYRATORY-CRUSHERS.pdf - RocketCDN

direction when the crusher is working. The older long-shaft gyratory crusher which has the gear above the eccentric (Fig. 23) has another difference in that

Learn MoreGyratory crusher upgrades - Outotec

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. Adding extra production capacity here can have

Learn MoreGyratory Crusher working site

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features Press Copyright Contact us Creators

Learn MoreGyratory Crusher Working

2021. 9. 18. · Gyratory Crusher Working. 211 working principle of gyratory crusher the gyratory crusher of citic heavy machinery company is mainly used in mines quarries metallurgy and other fields during its process of design and manufacturing we take full account of the influence the equipment has on human health and safety although some accidents can.

Learn MoreHow Does Gyratory Crusher Work

A Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing plant. Chapter 5. Gyratory and Cone Crusher - #2fishygirl on Scribd Power Consumption To compute the power consumption of gyratory crushers, knowledge of the ore work index and crusher capacity is necessary.

Learn MoreGyratory Crusher : Principle, Construction, Working, and

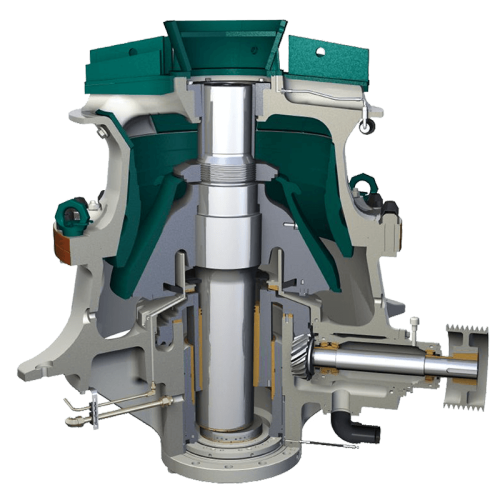

A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardness. Gyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic part, oil cylinder, pulley , appliances and dry oil, thin oil lubrication system components etc.

Learn MorePDF Gyratory crusher working principle pdf - southtours.comPDF

Gyratory crusher working principle pdf The working principle of the crushers on the left is an exhibition of the "Standard Shrine with straight concaves" is a section through any vertical plane, radial in the crushing chamber of one of the intermediate dimensions of the crusher. to understand the overwhelming action in such a room it is useful to consider the process as if each step took

Learn MoreTorque Analysis of a Gyratory Crusher with the Discrete

Comminution is the progressive reduction in size of run-of-mine (ROM) ore, and its initial stage is consists of primary crushing [1]. Gyratory crushers are the

Learn MoreWhat is the working principle of the Cone Crusher? - Quora

Specifically with a cone crusher, there are two cones that create pressure when they meet together at their apexes inside a chamber with gaps between them to

Learn MoreHow do a gyratory crusher work?

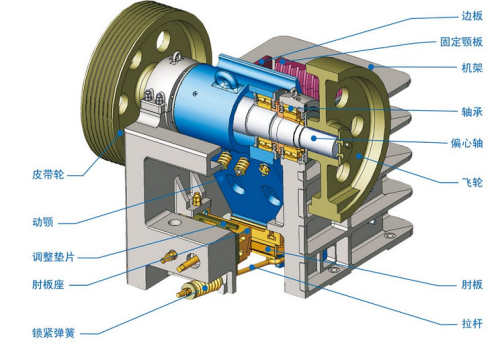

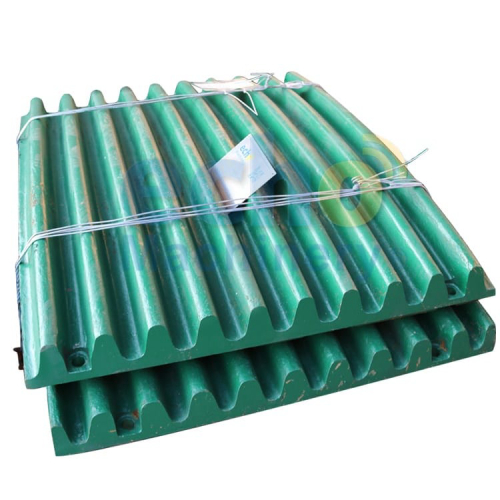

How do a gyratory crusher work? A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head with both the surfaces are typically lined with manganese steel liners. The inner cone has a slight circular movement, but it does not rotate. The movement is generated by an eccentric arrangement.

Learn MoreHow does Gyratory Crusher Works - Mineral Processing | Gyratory Crusher

In this video we will see what are the basic features of a Gyratory Crushers. Gyratory Crusher are used in Mineral Processing Industry for size reduction of

Learn MoreSuperior™ MKIII Series primary gyratory crushers - Outotec

Superior™ MKIII primary gyratory crushers bring safety and easy maintenance to any crushing plant. Hydraulic separation and individual lifting of shells creates a better environment for any workers on site working with the equipment. The SmartStation also improves operational safety.

Learn MoreWorking Principle of Crushers - Mineral Processing & Metallurgy

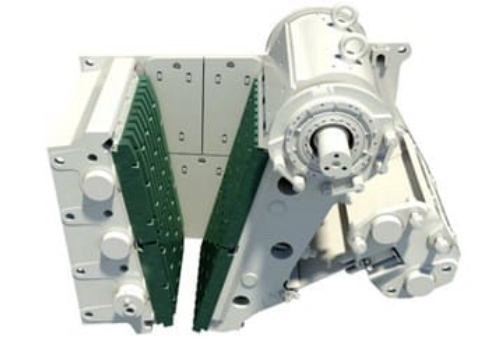

Gyratory Crushers are heavy-duty machines run in open circuit (sometimes in conjunction with scalping screens or grizzlies). They handle dry run-of-mine feed material as large as 1 m. There are two main types of primary crushers-gyratory crushers and jaw crushers. Gyratory crushers are the most common for new operations.

Learn Moregyratory crusher work and principles

What Is A Hydraulic Cone Crusher. 12 5 ensp 0183 ensp A hydraulic cone crusher actually is a cone crusher adopting the method of adjusting the discharging port by the hydraul

Learn MoreGyratory Crusher | Hazemag North America

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the

Learn MoreCone Crusher | Working Principle | Animation | Engineering Intro

Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from crushing chamber. Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones. It breaks the rocks by squeezing it between the gyrating spindles.

Learn MoreGyratory Crusher How It Works

Gyrating crusher broken cone of the cyclic movement of the cone cavity within the shell, squeeze the material, splitting and bending, rough chopped . What Is The Working Principle of Gyratory

Learn MoreA Detailed Overview of Cone Crushers and What You Need to

With cone crushers, a transmission shaft rotates the mantle, crushing material against the bowl. As the material is broken, it passes down the

Learn MoreWorking Principle of Crushers - 911 Metallurgist

Gyratory crushers work on a similar principle to jaw crushers but have a circular gap. Rock is compressed between a static conical bowl and a concave mantle which oscillates about the central axis. These are generally designed for primary crushing in large-scale rock crushing applications up to 6000 t/h.

Learn MoreGyratory crusher working principle pdf

2021. 5. 5. · Gyratory crusher working principle pdf The working principle of the crushers on the left is an exhibition of the “Standard Shrine with straight concaves” is a section through any

Learn MoreConstruction, Working and Maintenance of Crushers for

The crusher is the workhorse of the hard rock crushing industry. A gyratory crusher uses a mantle that gyrates (rotates) within a cone shaped inner surface.

Learn MoreGyratory crusher Definition & Meaning - Merriam-Webster

The meaning of GYRATORY CRUSHER is a mill for crushing ore or rock or other materials that consists of a cone-shaped burr rotating in the throat of a broad

Learn MoreCone crusher basics in 4 minutes — SRP

Inside your cone crusher. The basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber. · The open side and the

Learn More

Leave A Reply