Crushers - All crusher types for your reduction needs - Outotec

The main purpose of a primary crusher is to reduce the material to a size that allows its transportation on a conveyor belt. In most crushing installations a jaw crusher takes care of primary crushing. Plants with very high capacities that are common in mining and less popular in aggregates production, normally use a primary gyratory crusher.

Learn MoreCrusher - an overview | ScienceDirect Topics

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing stage

Learn MoreChoosing the Right Primary Crusher for Your Aggregates Application

One should start with the purpose of the crusher, move to model refinement and finish with a successful installation. The primary crusher is a workhorse that converts the blast feed size to a smaller size to manage for the other site components (belts, screens, and eventually any secondary crushers) on the path to the finished product.

Learn MoreHillsboro, OR - Crushers For Sale - Equipment Trader

Crushers are an important part of many industrial and materials processing projects. They allow for the crushing of rocks into gravel, smaller rocks, or even miniscule dust. Equipment Trader's website allows users to quickly search for the best models near to their zip code from the brands and dealers that they have come to trust.

Learn MoreGrizzly bars and feeders improve primary crushing efficiency

The primary jaw crusher is the first stage of processing in most sand, gravel, and mining operations. Material that has been excavated from the ground (Pit run) or blasted (Shot Rock) is fed to a large crusher, typically a jaw crusher, where it is crushed down to a manageable size for further processing.

Learn MoreCrushers and Their Types - IspatGuru

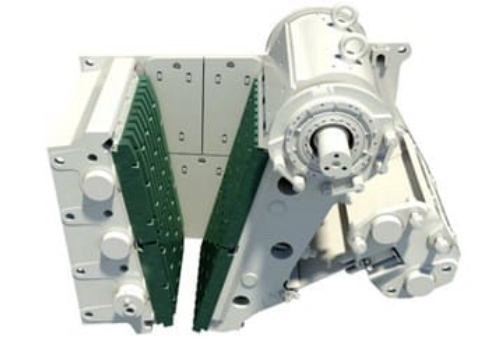

Jaw crusher is used as primary crusher. It uses compressive force for breaking the material. This mechanical pressure is achieved by the two jaws of the crusher. Reduction ratio is usually 6:1. The jaw crusher is consisting of two vertical jaws installed to a V form, where the top of the jaws are further away from each other than the bottom.

Learn Moreprimary and secondary crusher | bushing of ball mills picture

Jaw crusher,Jaw crushers,Primary crushers,Jaw breakers,Mobile The Jaw crusher is used for Primary crushers and Secondary crushers for crushing all kinds of minerals and rocks with compressive strength less than 320 mpa. Priy And Secondary Crusher Crusher.

Learn MoreLocations: Primary Care New : OHSU Health Hillsboro Medical Center

Locations: Primary Care New « back to Clinics & Locations. Immediate Care - Forest Grove. 1825 Maple St., Forest Grove, 97116 . Phone: 503-359-6180.

Learn MorePrimary And Secondary Crushing - Crusher Mills

Specially-designed Single Roll Crushers are utilized as Sinter Crushers with regard to primary crushing within the iron and metal industry. Double Roll Crushers are Crushed stone - North Carolina Geological Survey Home Page Primary crusher — rocks up to 5 feet by 4 feet by 4 feet are crushed to 8 inches in diameter or less.

Learn MoreWhat Is Primary, Secondary, and Tertiary Crushing?

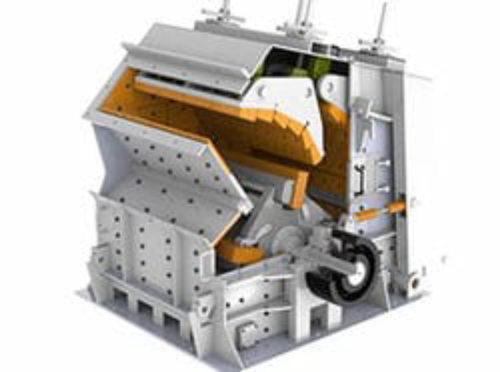

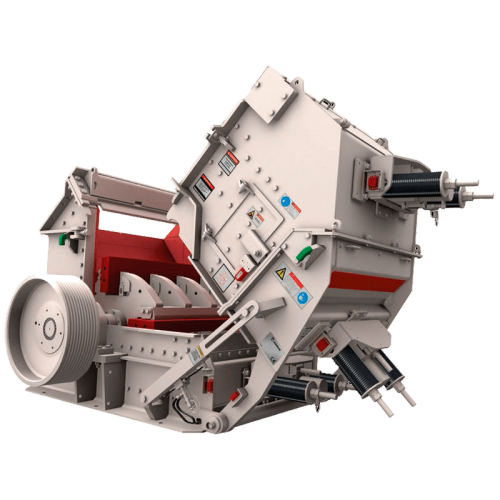

Depending on the setup, primary crushing will take the larger material that has been blasted, excavated, or reclaimed and process it through an impactor, jaw, or gyratory crusher to generate a range of product sizes.

Learn MorePrimary Jaw Crusher | Stone Crusher | FUREIN Machinery

The primary jaw crusher is mainly used to crush all kinds of stones. As long as the compressive strength of the stone is not more than 320 mpa, it can be broken. Primary crusher is essential equipment in the stone crushing and processing production line of high and medium hardness stone.

Learn MorePrimary Crusher - an overview | ScienceDirect Topics

The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour). The driving flywheel has a diameter of 2.5

Learn MorePrimary Crusher Selection & Design - Mineral Processing & Metallurgy

In in-pit crushing, the primary function of a crusher is to provide a smaller uniform product size for each of transport by the conveying system. Minimum power consumption in part of a good design. For their coarse duty, primary crushers use, comparatively lower energy, to other systems.

Learn MorePrimary Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

The primary crusher mainly refers to the jaw crusher and impact crusher. In the designing of a crushing plant of any nature and size, to select the right type and primary crusher , rock crusher - Detailed info for primary

Learn MoreMineSizer Primary Crusher | Run-of-Mine Crusher - Williams Crusher

The Williams MineSizer Primary Crusher is capable of handling a variety of materials including coal, limestone, and other soft minerals with moisture content up to 15-20%. Multiple sizes of this mineral crusher are available to accommodate a range of applications. Call us at (314) 621-3348 or email us at [email protected] for more

Learn MoreSteele Primary Crushers - Steele Machinery - J.C. Steele & Sons

Steele Primary Crushers — Cost-effective, reliable sizing for bulk raw materials Robust, workhorse machines built for decades of reliable sizing and consistent output, with minimal maintenance, easy wear part replacement and fast change outs for drives and roll speeds.

Learn MorePrimary crusher, Primary crushing and screening plant - All industrial

stationary primary. Capacity: 5 t/h - 1,100 t/h. Motor power: 15 kW - 280 kW. Opening height: 150 mm - 1,500 mm. Stone crusher is to break blocks of stone, mining ores, concrete and other building materials into a smaller specific grain size. It has types of jaw crusher, cone crusher, impact crusher,

Learn MoreChoosing the right crusher - Buying Guides DirectIndustry

It’s a primary crusher. The jaw crusher is a machine for crushing rocks and other hard and abrasive materials, such as granite, ores or recycled concrete, usually for industrial purposes. The crushing device consists of a fixed plate and a swing plate called jaws between which the rock is trapped and crushed.

Learn MoreSuperior™ MKIII Series primary gyratory crushers - Outotec

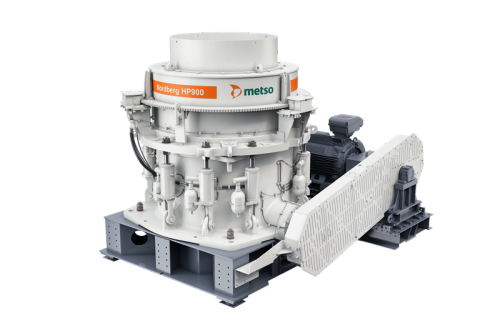

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. Outotec's Superior™ MKIII primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation. Higher throughput Increased speed, installed power and mechanical improvements. Reduced downtime

Learn MoreGyratory Crusher - an overview | ScienceDirect Topics

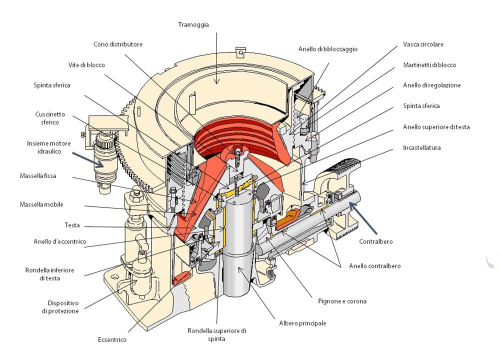

The larger crushers are normally known as primary crushers as they are designed to receive run-on-mine (ROM) rocks directly from the mines. The gyratory crushers crush to reduce the size by a maximum of about one-tenth its size.

Learn MoreWholesale Primary Crushing Manufacturer and Supplier, Factory

Primary Crushing - China Factory, Suppliers, Manufacturers. Using a total scientific good quality management process, superior high quality and excellent faith, we get great name and occupied this field for Primary Crushing, Sand Mining Machine , Ore Crusher , Aggregate Crushing Plant For Sale , Stone Breaker . Our products are widely

Learn MoreDifferent types of crushers for distinctive needs - Outotec

For instance jaw or gyratory crushers in primary crushing and cone crushers in secondary crushing. Primary crushing is for the robust. The very first crushers invented were jaw crushers, which are built to reduce the size of large materials and operate with high volume in primary crushing. Their main purpose is to reduce the material to a small

Learn MorePrimary Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

Jaw crusher,Jaw breaker,Jaw crushers,Stone crusher,Rock . It is mainly applied in the primary crushing in which the compressive strength of original material is under 320Mpa. Jaw

Learn MoreFABO Jaw Crusher / Stone Crushing CLK-110 - Werktuigen

Primary jaw crusher | 320T Stone crushe FABO Jaw Crusher / Stone Crushing CLK-110 - Werktuigen.com - Year of construction 2022 - Condition: New machine

Learn MoreGyratory Crusher Pro | manufactor | thyssenkrupp Mining

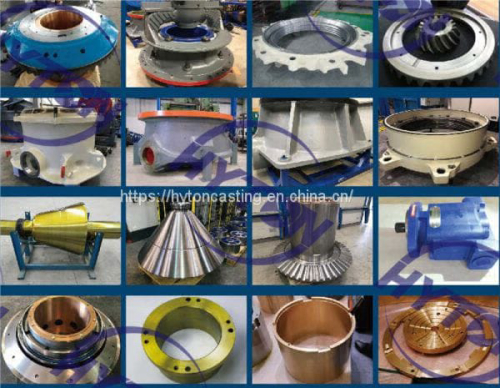

thyssenkrupp gyratory crushers represent today’s state-of-the-art. They are designed for high performance and, at the same time, cost-effective operation, i.e. low servicing and maintenance costs. Gyratories and jaw type gyratory crushers as an integral part of semi-mobile and stationary processing plants are used for primary crushing of bulk

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

It is inevitable for crusher to get wear because of long-time crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenance. 1 Check whether the tooth peak to tooth valley is match with each other. 2 Regularly check whether the bolts and nuts have been tightened so you must ensure that

Learn MoreWhat is a Jaw Crusher? – MEKA Crushing Equipment

Stroke (LT) Minimum and maximum movability of the lower end of the jaw. This is equal to the OSS minus the CSS. R: Size reduction ratio The ratio of the gape width to the near side jaw opening. This ratio may vary from 1/3 to 1/9, but is generally 1/3 for primary crushers and 1/4 for secondary crushers.

Learn MorePrimary Crusher — India

Primary Crusher Pulveriser Rock Breaker Telescopic Dipper Vibro Boom SPECIALTY EXCAVATORS SK350DLC CRANES CKL1000i CKL1350i CKL2600i Applications Genuine

Learn MoreWhat is a Primary Crusher? - Fabo

Primary crusher takse part in the first stage of crushing. Specifications of premier crushers used for crushing medium-hard and non-abrasive stones are: It performs best for non-hard

Learn MorePrimary And Secondary Crushing | Crusher Mills, Cone Crusher, Jaw Crushers

Primary and Secondary Crusher Hammers – Wear Parts + Steel Our H79 alloy steel hammers provide reliable, consistent service for secondary and primary crushers. H79 is a high strength alloy steel with a hardness of 477-512 HB.

Learn MoreDifferent Types Of Crushers Machine Of Primary,secondary And Tertiary

Secondary Crusher, Tertiary Crusher, Quaternary Crusher For Fine crushing circuits are more challenging than primary crusher. Secondary Crusher, Tertiary different installation and the crusher. cone crushers have three types

Learn More

Leave A Reply