AMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

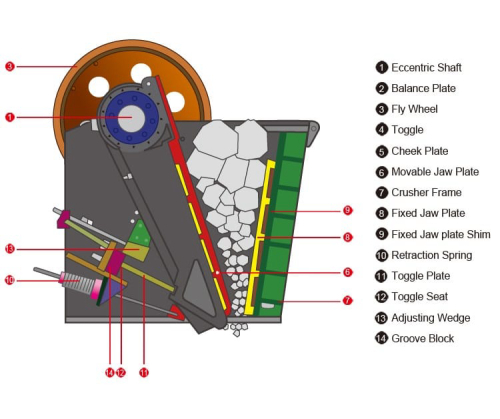

Jaw Crusher · Crushing occurs between two moving plates that are arranged to form an acute angle to apply a compressive force that results in tensile failure

Learn MorePrimary crushing selection jaw crusher - Zhongxin Heavy industry

Primary crushing selection jaw crusher Strong durability: the jaw crusher adopts good production materials, the bracket adopts high-strength steel plate material, and the advanced digital parts processing equipment is used to make the internal structure of the crusher precise. 4. Stable operation: As a head crushing equipment, stability is

Learn MorePDF Primary size reduction with Jaw Crushers - McCronePDF

Jaw Crusher BB 300 8-9 - Selection guide / technical data 10 - Breaking jaws 11 - Order data 12 Milling - Jaw Crushers - Rotor Mills - Cutting Mills RETSCH Jaw Crushers are used for the rapid, gentle crushing and pre-crushing of medium-hard, hard, brittle and tough materials. The variety of materials

Learn MoreAC drives prolong crusher lifetime and optimize electricity use

selection of which depends on the material quality and the quantity of material demanded. However, hammer and jaw crushers are commonly used.

Learn MoreConsiderations when choosing a concrete crusher

Impact crushers. While jaw crushers use compression to break up concrete, impact crushers use impact (as their name implies). Material is

Learn MoreWhat Type of Crusher Is Best for Primary Crushing?

Jaw Crushers are another excellent choice for primary crushing applications because they can accept the toughest, hardest, most abrasive

Learn MoreJaw Crusher - an overview | ScienceDirect Topics

Jaw Crusher. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. From: Mineral

Learn MoreJaw Crusher Selection Criteriain Uzbekistan-HN Mining

Primary crusher selection design the rated capacity at 5 closedside setting was 490 stph based on standard 100lbsft3 feed material these crushers were fed a very fine ore over a 4 grizzly which allowed the 1000 tph the sag mills needed for crushing operations under 500 tph the design engineer will typically select a jaw crusher as they are of

Learn MoreChoosing the right crusher - Buying Guides DirectIndustry

Read our buying guides and make the right choice The jaw crusher is a machine for crushing rocks and other hard and abrasive materials, such as granite,

Learn MoreHow to Select the Right Jaw Crusher - Gilson Company

The selection of the best jaw crusher for your application will naturally be governed by the particle size, volume, and properties of your bulk material, along

Learn MoreJaw Crushing Selection - Crushing, Screening & Conveying - Metallurgist

Jaw crushers are divided into four types including CJ series jaw crusher, HD German jaw crusher, PE series jaw crusher, PEX series jaw crusher and mobile jaw crusher.Jaw crusher is composed of main frame, stationary jaw plate, movable jaw plate, movable jaw, eccentric shaft, toggle plate, adjustable toggle seat.

Learn MorePrimary Crusher Selection & Design - 911 Metallurgist

How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG,

Learn MoreWEAR IN STONE CRUSHER PLATE - IJARIIE

A suitable material selection may avoid the this failure an improve the life of jaw crushers. Keyword: - Jaw crusher, Crushing, Abrasive wear, material.

Learn MoreJAW CRUSHERS | GELEN

CK series jaw crushers are your reliable partner in the toughest feed conditions. With a wide range of size selection GELEN jaw crushers offer you the most

Learn MoreStationary jaw crushers - rockprocessing

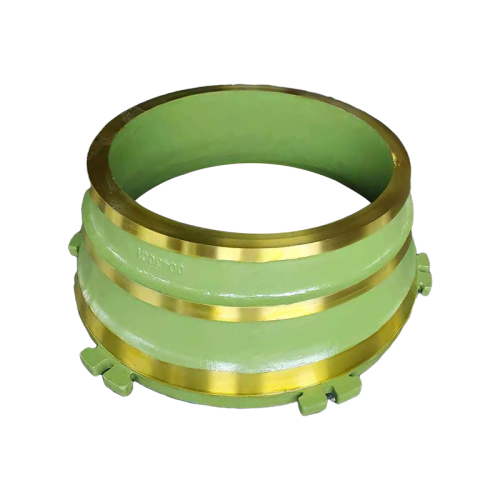

offers seven teeth patterns and up to three alloy selections (M1, M2, M8) to suit the different types of quarrying and mining applications. Our patterns

Learn MoreJaw Resources | MPS

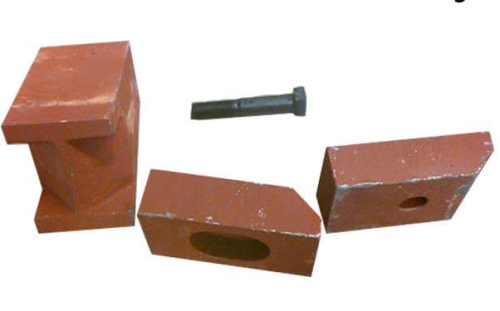

Swing Jaw. Replaceable die plate attached to the pitman. Bolt on wear plates designed to protect crusher frame. Some designs of jaw crushers require wedges to ensure that the jaw plates are held firmly in position. These are also a wear part that can be replaced when worn down.

Learn MoreSelecting the Right Crushing Equipment | Agg-Net

In most aggregate crushing plants, primary crushing is carried out in a jaw crusher, although a gyratory primary crusher may be used.

Learn MoreNews - Crusher Jaw Plates Material Selection

Compare with Mn18Cr2 crusher jaw plates, its span life can 1.5-2.5 times. This material just suits wide tooth or super tooth jaw plates, not suit shape tooth jaw plates. Alloy Steel Crusher Jaw Plates. These alloy steel jaw plates just use to magnetic separation stone, and the jaw plate weight less than 500 kg. Its elements: C 0.40%; Mn 1.9%

Learn MoreSelection of a structure of jaw crusher regulator - IOPscience

It should be taken into account that a modern jaw crushing machine is not only an element of a crushing and screening complex, but it is also a system in itself

Learn MoreSelecting the right crusher : Pit & Quarry

A jaw crusher is a compression type of crusher. Material is reduced by squeezing the feed material between a moving piece of steel and a stationary piece. The discharge size is controlled by the setting or the space between those two pieces of steel. The tighter the setting, the smaller the output size and the lower the throughput capacity.

Learn MoreAnalysis of the Single Toggle Jaw Crusher Force ... - Hindawi

The force transmission characteristics can be used as criteria for the comparison of different jaw crusher mechanism designs in order to select the most

Learn MoreCrushers Selection Guide: Types, Features, Applications

Feed size, material, and hardness must be considered. · Output size ranges. · Crushers accept dry or wet input, or both. · Crushers are feed in batches or

Learn MoreSelection Of The Material Of Jaw Crusher Plate – Jaw Crusher

Selection Of The Material Of Jaw Crusher Plate The impact of jaw plate wearable reason is mainly wear-resistant material hardness and toughness. ① material is too hard, the material extrusion depth is shallow, the material deformation is small, the material for material short-range sliding chisel cut is also small;

Learn MoreJaw Crushers | McLanahan

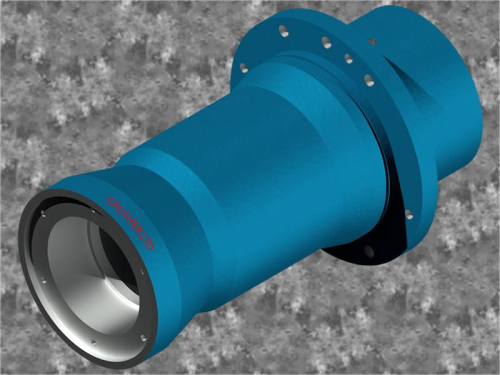

Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers. On the overhead eccentric style Jaw Crusher, the moving swing jaw is

Learn MoreSelection Of The Material Of Jaw Crusher Plate - Jaw Crusher Wear Parts

Selection Of The Material Of Jaw Crusher Plate 0 0 0 The impact of jaw plate wearable reason is mainly wear-resistant material hardness and toughness. ① material is too hard, the material extrusion depth is shallow, the material deformation is small, the material for material short-range sliding chisel cut is also small;

Learn MoreChoosing A Jaw Crusher | Tricon Mining Equipment

What is a Jaw Crusher? Jaw crushers are sometimes also referred to as “rock breakers,” which speaks to their brute force. They are nearly exclusively used as

Learn MoreStone crusher selection jaw crusher_Zhongxin Heavy Industry

Stone crusher selection jaw crusher. Author: Time:2019-12-04. Stone crusher processing can be used in road repair, construction and other industries. Efficient and high-yield has become the pursuit of stone processing plants. So which crusher to choose to achieve this requirement? Jiaozuo Zhongxin's * recommendation is a jaw crusher for the

Learn MoreSeven Processes for Model Selection of Small and Medium Jaw

The key point is the quality of the wear-resistant materials of the jaw crusher, such as the jaw plate, lining plate, tooth block and other parts, which are very easy to be damaged in

Learn MoreMaterial Selection of Jaw Plate of Jaw Crusher

Therefore, it is necessary to fully understand the working conditions and select materials reasonably. 1. Improve the hardness of the jaw plate. The larger the size of the jaw crusher, the larger the size of the crushed material, and the greater the impact load the jaws bear. When selecting the material, the first consideration should be to

Learn MoreCrusher - an overview | ScienceDirect Topics

Crusher. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. From: Mineral

Learn More5 Common Questions about Jaw Crushers Answered

While jaw crushers may always be a smart primary crusher stage choice for many operations, it's true that newer cone crushers are

Learn More

Leave A Reply