60 Duro Mill shell & liner backing rubber | Mill Backing - Reglin Rubber

AVAILABLE SIZES. Mill Backing Lining Rubber can also be supplied in cut lengths, strips, pads and a wide variety of custom cut shapes and gaskets to suit your application requirements. PART NUMBER. DESCRIPTION. WEIGHT (PER L/M) MB061200. Mill Backing Rubber With Buffed Back 6mm x 1200mm (10 L/M Rolls) 9.7 kgs. Product Information Sheet.

Learn MoreSAG Ball Mill Rubber Lining Supplier - EB Castworld

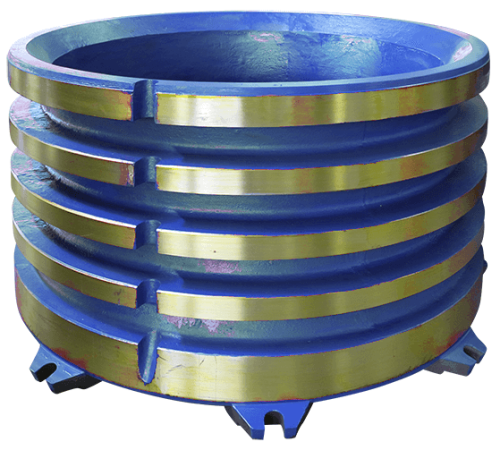

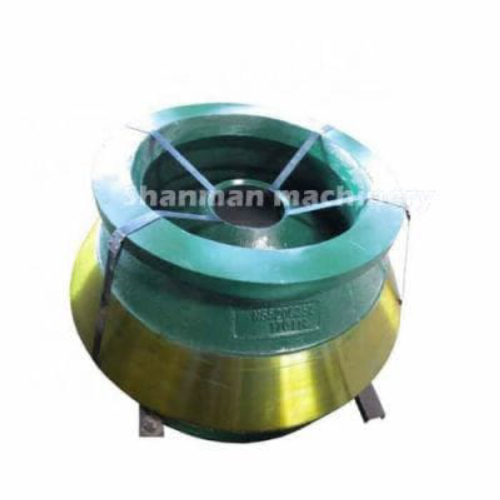

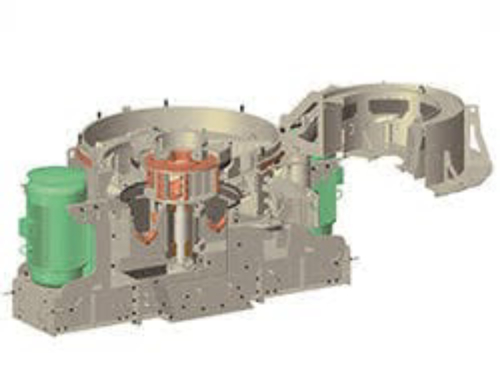

The SAG Ball Mill Rubber Lining is particularly made by anticorrosion and antiabrasion rubber with lighter weight, longer life span, low power consumption,high wear and impact resistance, low noise, easy to install, saving the ball. Mill Size: Φ2400×1000, Φ3600×3500, Φ4000×1400, Φ4000×6000, Φ5500×1800, Φ6000×3000, Φ6000×2800, etc.

Learn More60 Duro Mill shell & liner backing rubber

Mill Backing Lining Rubber has been designed primarily for use as a wear and corrosion protection lining system. It is designed specifically to be used as

Learn MoreRubber Mill Liners | AG SAG Ball Mill Liners | GTEK MINING

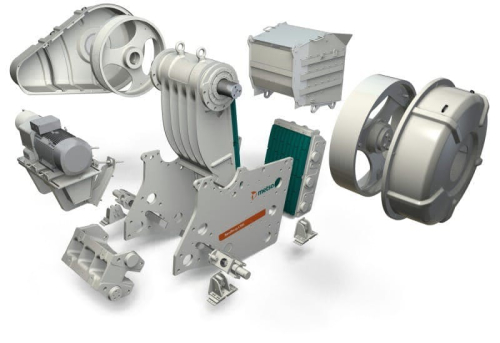

① Lower Cost: Our rubber mill liners are relatively cost effective as "cost per ton of ore grind" is lower;. ② Longer Life: Our rubber mill linings have "longer operational life";. ③ Less Maintenance: Rubber mill liners are engineered to resist abrasion, increasing the maintenance interval;. ④ Faster/ Safer: Rubber mill components are lighter in weight and easier to handle when changing;

Learn MoreRubber - Growth Asia

Years as a leading global mill-lining system supplier has given us insight into the complementary functions of steel and rubber liners - we understand how

Learn MoreChina Rubber Liner,Cement Ball Mill Liner Plate,Abrasion Resistant

Wear Resistant Ball Mill Rubber Shell Plate. Min.Order. Unit Price. 50 Kilogram. USD 1.9 / Kilogram. Rubber Liner is mainly used in AG Mill, SAG Mill, Ball mill, Bar mill and other grinding equipment for mining, cement, chemical industry, building materials, metallurgy and other fields. The advantages of Abrasion Resistant Rubber Liners are as

Learn MoreRubber Liner Characteristics & Specifications - Grinding

which rubber is excellent for ball mill rubber liners? what should be physical properties and qualities of ball mill rubber liners?

Learn MoreRubber Mill Liners - Multotec

Rubber Mill Liners Multotec: protect mineral processing equipment from wear, abrasion and impacts. Supported globally. Monitoring software available.

Learn MoreVulco® Mill Lining Systems - Minerals

Vulco® mill lining systems: revolutionary rubber liners that provide exceptional wear life and reliability. Mill liner experience and expertise.

Learn MoreBall Mill Linings | Multotec

Ball Mill Linings from Multotec provide optimum wear lining solutions for the toughest applications, ensuring optimum grinding and crushing efficiency. Our Ball Mill Lining designs are manufactured with rubber or rubber composite materials to meet your specific requirements. Light to medium sized Steel Liners is also available for additional

Learn MoreMill Linings for Sale, Types of Ball Mill Liners. - ball mills supplier

Ball Mill Rubber Liner. The rubber linings produced by AGICO CEMENT can generally be divided into ball mill rubber linings, rod mill rubber linings, tube mill rubber linings, AG mill rubber

Learn MoreBall Mill Rubber Liner - IndiaMART

SAKAR's ball mill rubber liners are pressure moulded to ensure highest density and engineered for maximum abrasion resistance.

Learn MoreFlexible Rubber Liner Manufacturer,Mill

KEDAR RUBBER PRODUCTS, We are finest Manufacturer,Supplier and Exporter of Flexible Rubber Liner and Mill Liner Plate from Ahmedabad, Gujarat, India.

Learn MoreRubber Ball Mill Liner | Vostosun - Mineral Processing

The density of these wear resistant rubber liners is about 1/6 that of steel rubber liners, which reduces the cylinder weight, which in turn reduces the motor load during operation. The rubber ball mill liner material features a special structure, and has been formed using a high pressure vulcanization process. Gallery

Learn MoreHome [ballmillrubberliner.com

Ball mill shell liners are used to protect the inner shell of cylinder from being impacted and worn directly by material and grind-ball. At the same time we can use different forms of the shell liners Read More, HEAD LINERS (TRIANGLE)

Learn MoreRubber Mill Liner (@rubbermillliner) • Instagram photos and

Rubber Mill Liner. Product/service. Dünyanın Lider Kauçuk Değirmen Astar ve Lifterbar Üreticisi The World's Leading Rubber Mill Liner Manufacturer

Learn MoreRubber liner - Monster Belting

Ball Mill Liner/Rubber liner for Cement Plant. GENERAL DESCRIPTION. Rubber liner provide optimal grinding solutions in major mineral processing plants all

Learn MoreRubber Liner > ATEMS

Rubber Liner for Ball Mill (Overflow & Grate Discharge) / Batch Mill/ Continuous Mill- Lifter Bar (with Aluminum or without Aluminum), Shell Plate,

Learn MoreSteel vs Rubber Mill Liners - Qiming Machinery

07/09/ · In the former case, steel mill liners would be preferred and rubber liners would be preferred otherwise. This is because, when lifter bars are in close proximity, there is an impact that rubber cannot handle very well, but when they are far apart, abrasive grinding increases, and thus the benefit of rubber mill liners significantly increase.

Learn MoreFKK Güney Oto Lastik Takoz San. ve Tic. A

Rubber mill linings are nearly 75% lighter than steel linings, thus failures in mill bearings and the lubrication system are being minimized. The holes of

Learn MoreRubber mill liners - Outotec

Outotec has 60+ years of experience of developing rubber mill linings for grinding mills. Choose a long-lasting rubber mill liner from our wide

Learn MoreKey considerations when selecting a mill lining system - The Weir

27/01/ · Figure 2: Cascading-impact action in a SAG mill. Rubber and composite mill lining systems. In the past, grinding mills were typically lined with cast metal linings of varying steel or iron alloys, and lining system selection was typically driven by level of wear protection and cost. As materials technology and design technique has advanced

Learn MoreMill Liner Market Size, Industry Share | Forecast, 2029

Within rubber and steel mill liners, rubber mill liners are easier and quicker to install owing to, its properties such as, lightweight, excellent wear

Learn MoreMill Lining Systems | FluidHandling - Trelleborg

Trelleborg has a wide range of rubber lifter bars and plates for ball mills, rod mills and drum scrubbers. Our MILLTOUGH® EXTREME composite lifter bar is

Learn MoreBall Mill rubber Liner

Most of all type of Ball Mill Liner are always used to protect the inner shell of the cylinder from being impacted and worn directly by material and

Learn MoreBall mill Rubber lining - Kedar Rubber Products

Advantage of Ball Mill Rubber Lining ; 1. Reduced Weight · The rubber lining parts are about 1/4 less weight of brick liners of same size. ; 2. Reduced Power

Learn MoreRubber Ball Mill Liner - Strudex Mining

Rubber Ball Mill Liner Linings. Rubber linings are lightweight and easy to handle. Rubber mill linings show more wear resistance and require less maintenance. Rubber mill linings absorb

Learn MorePolycorp - Rubber Liners

Rubber Mill Liners are extensively used in FGD mills at Power Plants all over the world. Polycorp has supplied complete rubber linings in some of the largest ball mills in South America at 26

Learn MoreMill Liners Filterui ImagesizeLarge

Mill Liners Filterui ImagesizeLarge 2018-07-06T21:07:30+00:00. камнедробилка гравийная . камнедробилка гравийная . щековая дробилка для продажи jan . щековая дробилка для продажи jan .

Learn MoreBall mill rubber liners | Rubber liner Manufacturer in india | Mill

Kedar rubber is one of the leading Manufacturer and exporter of Rubber liner and mill rubber liners in Ahmedabad, Gujarat and India.

Learn MoreBall Mill Rubber Lining Rubber Liner

Rubber liner is mainly used in AG Mill, SAG Mill, Ball mill, Bar mill and other grinding equipments. Customers cover mining, cement, chemical industry, building

Learn More

Leave A Reply