Jaw Crushers - MEKA Crushing & Screening Plants

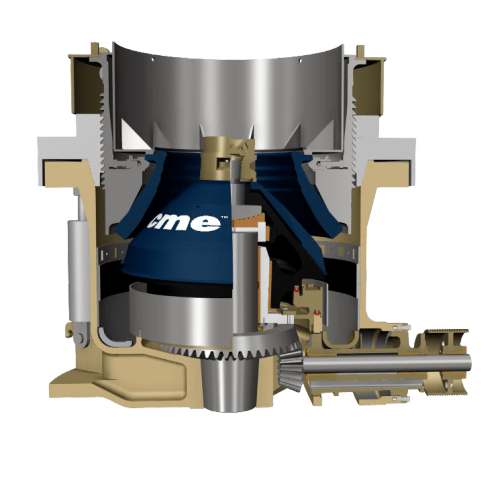

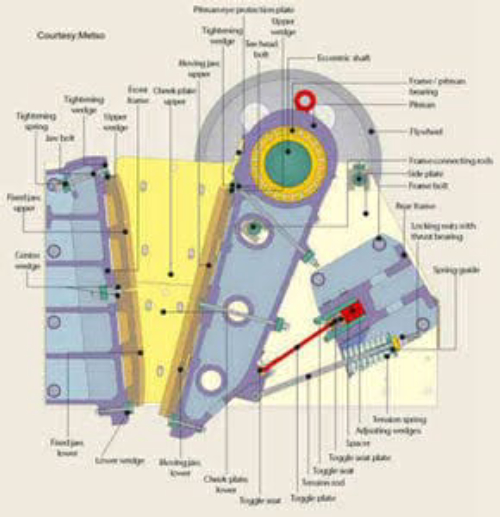

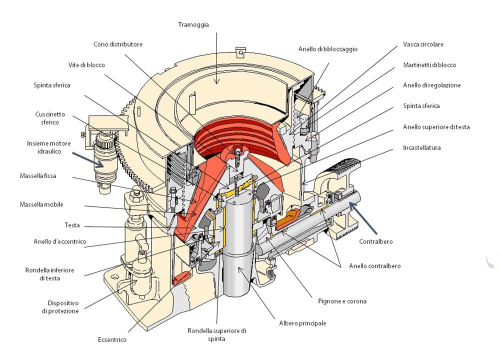

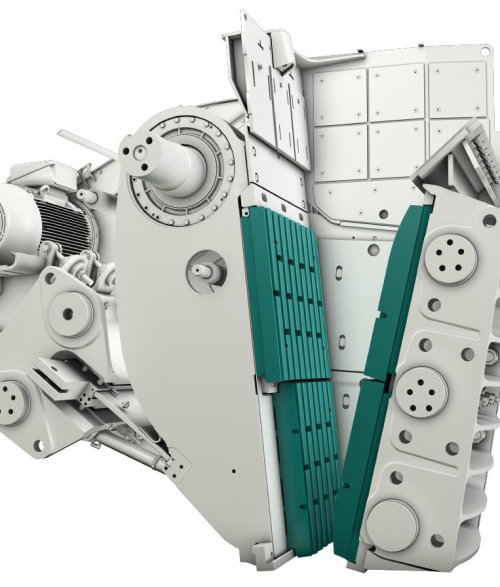

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds

Learn MoreCrusher Jaw Plate Manufacturer from Jaipur

Manufacturer of Jaw Plate - Crusher Jaw Plate offered by Shree Engineering Works, Jaipur, Rajasthan.

Learn MoreResminer Stone Crusher Jaw Plates - Wear Resistance Supplier in China

The pattern of stone crusher jaw plate was used in this process to achieve the shape of the stone crusher jaw plate. Pouring Melted Chemical When the raw material turns into liquid, it will be transferred to the machine outlet to get the desired shape. Heat Treatment Process A modern and high-tech furnace machine is used in this procedure.

Learn MoreCrusher Jaw Plates For Popular Brands By Hunan JY Casting

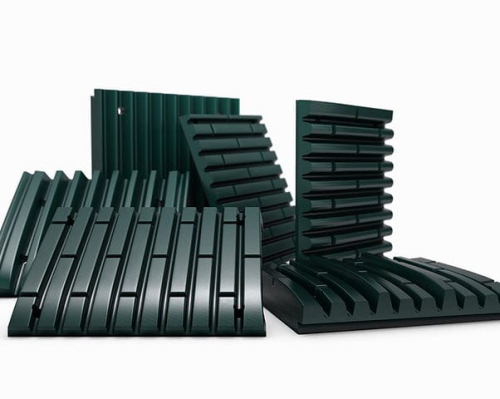

Premium Crusher Jaw Plates. The crusher jaw plates are the main wear-resistant parts installed on the machine body to squeeze and crush the stone. Normally, it consists of a 1 piece fixed

Learn MoreJaw Crusher - an overview | ScienceDirect Topics

Rose and English [9] determined the capacity of a jaw crusher by considering the time taken and the distance travelled by the particles between the two plates after being subjected to repeat crushing forces between the jaws. Therefore, dry particles wedged between level A and level B (Figure 4.4) would leave the crusher at the next reverse movement of the jaw.

Learn MoreCrusher Jaw Plate Latest Price, Manufacturers & Suppliers

We are the renowned company in offering Jaw Crusher Plate to our clients. This product is widely appreciated in the market for high strength and resilience.

Learn MoreHow does a Single Toggle Jaw Crusher work? - Rubble Master

The two jaw plates are positioned in a V-shape so that the space narrows from top to bottom. The angle within the V is known as the nip angle. An elliptical

Learn MoreJaw Plates - John Moore Wear Parts UK

Jaw plates of varying manganese contents are also available; 13/14%, 18% and 22%. Powerscreen Premiertrak 400/R400 Jaw Crusher Box.

Learn MoreCrusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 2

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Top models for sale in HILLSBORO, OREGON include C3R and C4

Learn MoreHow to Choose the Right Jaw Plates for Jaw Crushers - Ware

05/11/ · The jaw crusher is a single toggle type of crushing equipment mainly used for variety of applications, including the medium to fine crushing process in the fields of mining, chemical industry, building materials, and refractories. As its name implies, this machine functions by using the “jaw plate,” which is derived from its wear-resistant

Learn MoreJaw Crusher Toggle Plate Teeth Plate / Impact Crusher Liner Plate

Counterattack plate breaking hammer is made of high chromium material. Compared with common high manganese steel hammer, it has the characteristics of high hardness, fine discharge and high wear resistance. The high hardness martensite matrix in the hammer can strongly support carbide particles, avoid the carbide falling off from the wear surface during the working process, and ensure the high

Learn More4109930 crusher toggle plate | pin number on hp printer

Caterpillar Crusher Toggle Plates. Jaw Crusher Toggle Plate Wholesale, Plate SuppliersAlibaba. Alibaba offers 1,360 jaw crusher toggle plate products. About 56 of these are crusher, 32 are mining machinery parts, and 1 are steel sheets. A wide variety of jaw crusher toggle plate options are available to you, such as astm, aisi, and bs. Small

Learn MoreJaw Crusher Wear Parts - Columbia Steel Casting Co., Inc

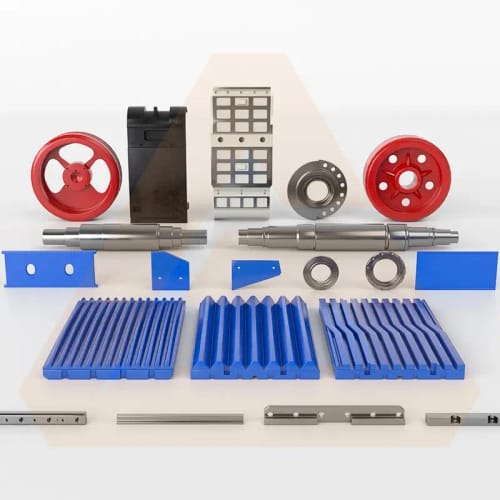

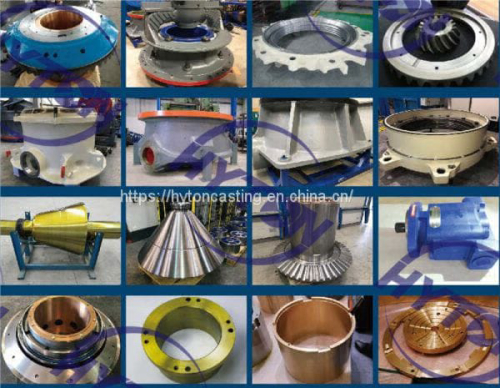

Columbia Steel manufactures the world's largest number of jaw designs. Wear parts for all popular jaw crushers, include: jaw dies, cheek plates, and more

Learn MoreJual Jaw Plate Terlengkap - Harga Terbaru September 2022

Jaw Plate PE 150 x 250 / Jaw Crusher 1 set. Preorder Tooth Plate Jaw Crusher Penghancur Batu Sparepart 1 Set 2 Pcs PS1218. Rp1.650.000.

Learn MorePioneer® Jaw Crushers - Astec

The Pioneer ® Series of jaw crushers represents the very latest in jaw crusher technology.. Engineered to be the highest-capacity jaw crusher on the market, the Pioneer ® Jaw Crusher will deliver up to 25 percent more tons per hour than comparable jaw crushers. Pair that with heavy-duty flywheels for reduced horsepower requirements and class-leading stroke for higher capacity and you have a

Learn MoreJaw Rock Crusher - BUILD Ep.5

20/08/ · Fabricating a jaw rock crusher from scratch. Making the toggle plate mount and fabricating a dedicated trailer using scrap steel.What is a jaw rock crusher -

Learn MoreJaw Plate Manufacturer | Bowl Liner | Blow Bar - Casteel Foundry

Our full-line of products from VSI Parts bucket Teeth ,hammers,blow bars To large Concave, Mantle , Jaw plates, Grates Mill Liners and much more have been highly recognized among customers and used in wide range of applications. 50MM CORRUGATED 504-015-083 J40 SWING JAW DIE GENERIC MODEL 504-003-022 C40 JAW DIE STANDARD PROFILE Mccolskey

Learn MoreHow To Change Crusher Jaw Plate? - MGS Casting

Lift the new jaw plate, and start the crane to hang the moving plate and the fixed plate separately. Install the clamps, place the clamps in place, and tighten the screws. Tighten the stationary plate screws and install the side plates. Adjust the gap of the discharge port. Start the jaw crusher and vibrate the mine for trial operation.

Learn MoreJaw Crusher - Jaw Crusher Mannufacturers | AGICO Cement

The crushing part of the jaw crusher is composed of two jaw plates, one is a fixed plate, which is vertically fixed on the inner front wall of the machine body, the other one is a movable plate, which is inclined and fixed to form a wide upper and narrow lower crushing cavity with the fixed plate. The movable jaw plate makes periodic

Learn MoreHow to get the most wear life out of your rotatable one

One-piece and two-piece jaw plates for ® C Series™ jaw crushers are rotatable. But how do you know when to rotate the jaw crusher plate

Learn MoreJaw Crusher Wear Parts - Unicast Inc

Increase machine up-time with Unicast Jaw Crusher replacement wear parts including jaw plates, cheek plates, wedges, and toggles.

Learn MoreJaw Crusher - Eastman Rock Crusher

1-1120t/h. Output Size. 10-350mm. Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications. mining, quarry, construction waste recycling, aggregate making, etc. Materials.

Learn MoreJaw Crusher Plates - Wear Parts For Industry | Qiming

Liner Plate And Cheek Plate. Qiming Casting offer the complete range of liner plates and cheek plates for all kinds of brands jaw crushers range.The liner plates have an important role to play

Learn MoreWhat is a Jaw Crusher? - MEKA Crushing Equipment

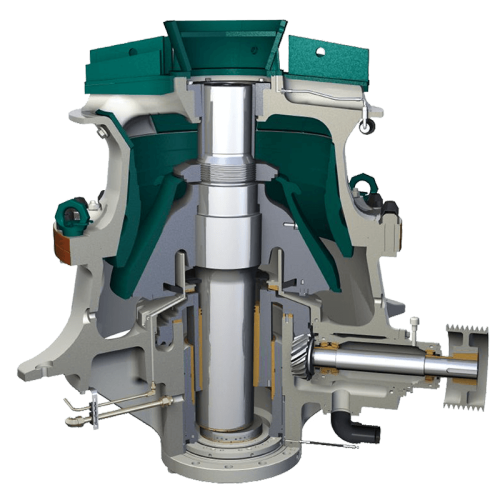

Single-toggle jaw crushers - Double-toggle jaw crushers. In single-toggle jaw crushers, the movable jaw is supported by the bearing on an eccentric shaft driven by the pitman to which it is attached. The pitman is supported by a toggle plate at the bottom of the moveable jaw. Toggle plate compressed between moveable jaw and main body.

Learn MoreA Review on Study of Jaw Plates of Jaw Crusher

of swing jaw plate. I. Introduction. A Jaws crusher consist of two plates one job being fixed and other being mount by pitman mechanism due which.

Learn MoreDesign and Analysis of Swing Jaw Plates of Jaw Crusher

Jaw crusher is one of the main types of primary crushers in a mine or ore processing plant. The size of a jaw crusher is designated by the rectangular or square

Learn MoreSource The Ideal Wholesale jaw crusher plate

Create fine powders for industrial projects with crusher machines. Browse the jaw crusher plate range on for all types at wholesale prices.

Learn MoreWhat happened? Jaw plates which need to change frequently for jaw crusher!

Our replacement jaw feature in three grades depending on the crushing conditions encountered 13%MN, 18%MN, 21%MN. BDI's replacement jaws offer to wear life and fit and go through a rigorous quality control process. Benefit: Proprietary alloys offer increased toughness and durability. Better fit for quick and easy replacement

Learn MoreJaw Plate Crusher Jaw Plate Price Discount - EB Castworld

11/05/ · The jaw crusher is composed of a working cavity composed of movable and fixed jaws. Movable and fixed jaws bear huge crushing force and friction of materials, and are easily

Learn MoreJaw Plates: How to Choose the Right One for Different

Generally, a jaw crusher finishes the crushing process by squeezing the material between stationary and

Learn MoreJaw Crushers - Mt Baker Mining and Metals

Baker Mining and Metals' jaw crushers are industrial grade, continuous duty machines. They take large pieces of rock, ore, concrete, or other materials, and crush them down to smaller sizes, for further processing in a ball mill or hammer mill, or for use in ballast or fill applications. Diesel Powered Jaw Crusher / Rock Crusher

Learn More

Leave A Reply