Leopard Vinyl Designs Company Profile | Hillsboro, OR | Competitors

Find company research, competitor information, contact details & financial data for Leopard Vinyl Designs of Hillsboro, OR. Get the latest business insights from Dun & Bradstreet.

Learn MoreJaw Crusher Working Principle - Mineral Processing

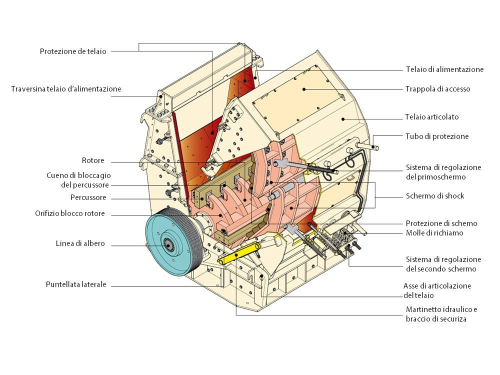

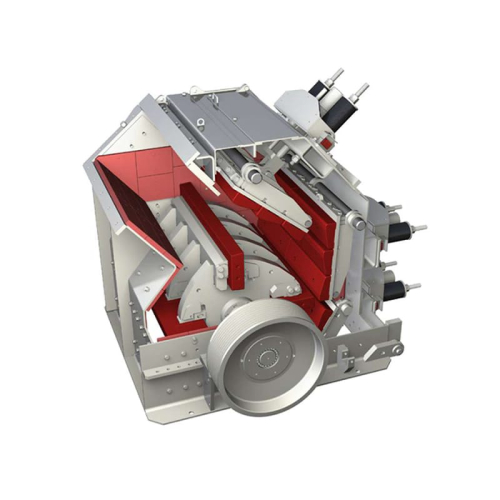

5/6 · Metallurgical ContentJaw Crusher TerminologyJAW CRUSHERSDouble-Toggle Jaw CrushersSingle-toggle Jaw CrushersSizing Jaw CrushersForced Feed Jaw

Learn Morejaw crushers for all your needs - Lutze Process

We've been designing jaw crushers, All our jaw crushers are of the single toggle type, with a deep, the swing jaw. Lubrication-free toggle-plate.

Learn MorePDF) Optimum design and analysis of (the) swinging jaw plate of a

The design of swing jaw plate is carried out by using CAD i.e., jaw plate has been solid modeled by using CATIAV5R16. FEA is applied to assembled structure of swinging jaw plate and lever to

Learn MoreJaw Crusher Components & Parts - Mineral Processing & Metallurgy

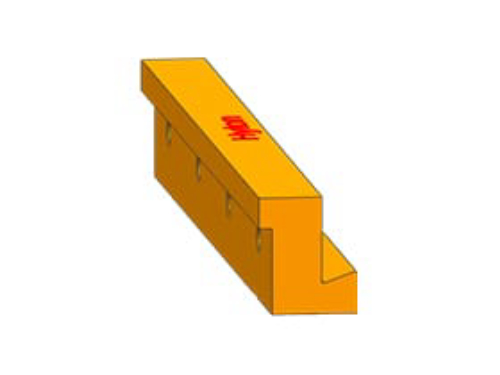

With some designs the toggle plates are made up of two steel plates that are bolted together with what is known as SHEAR BOLTS. These are bolts that have a known shear strength. If something that the crusher cannot crush accidentally gets into the crushing chamber these bolts will shear off when the Jaw hits the unbreakable object.

Learn MoreOregon Hillsboro License Plate Frames - CafePress

Find great designs on durable and weather resistant License Plate Frames to make your car stand out! Free Returns 100% Satisfaction Guarantee Fast Shipping (844) 988-0030

Learn MoreJaw Crusher - Eastman Rock Crusher

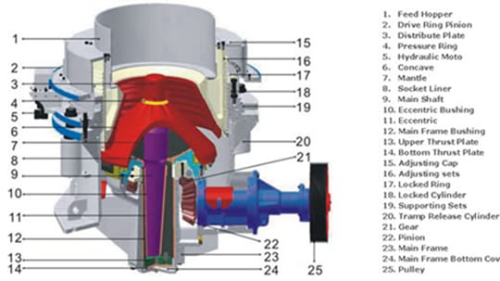

Capacity. 1-1120t/h. Output Size. 10-350mm. Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications. mining, quarry, construction waste recycling, aggregate making, etc. Materials.

Learn MoreAW hydraulic toggle - Automatic Welding

Automatic Welding Inc. designed and built the patented "Hydraulic Toggle" adjust and relief system for jaw crushers, reducing the time for jaw adjustment

Learn MoreBuilding a Double Toggle Jaw Crusher - Crushing

The kinematic analysis of single toggle jaw crusher shows that the forces on the moving jaw plate at different crank angle are different and hence power

Learn MoreJaw Crusher - an overview | ScienceDirect Topics

Many jaw crushers are protected from such “tramp” material (often metal objects) by a weak line of rivets on one of the toggle plates, although automatic trip-out devices are now common. Certain designs incorporate automatic overload protection based on hydraulic cylinders between the fixed jaw and the frame.

Learn MoreSingle Toggle Jaw Crusher With Unique Benefits

Double toggle jaw crusher is designed for the hardest stones and rocks, And when the swing jaw plate leaves the fixed one, the crushed ore is discharged

Learn MorePDF) Selected design issues of toggle plate selection on

Abstract and Figures. The article presents the problem of increasing the performance of the jaw crusher, reducing the crushing power and moment.

Learn MoreWhat Are the Functions of Toggle Plate of Jaw Crusher ... - Zoneding

Toggle plate is a power transmission part of jaw crusher. It is used to support movable jaw plate and transmit crushing force to the back of body frame. Adjust discharge opening Adjust the outlet of jaw crusher by way of changing the size of toggle plate. It has two specific ways to adjust the outlet.

Learn MorePDF Engineered for the toughest feed materials ® C Series™ jaw crushersPDF

The unique three cylinder concept prevents the pitman bearings from twisting and ASC also includes a toggle plate for optimum jaw crusher protection. Safe and effortless operation and maintenance The setting of the C Series jaw crusher can be adjusted with two wedges without shim plates.

Learn MoreCJ615 Single-Toggle Jaw Crusher With Heavy Duty Design

CJ615 Jaw crusher. CJ615 single-toggle jaw crusher is engineered for even the toughest applications thanks to its heavy-duty design. Characterized by an attention to detail in its design and manufacture, this machine is an excellent choice when you need high production and low total cost. Email us Request a quote.

Learn MoreJaw Crusher Toggle Seat Suit C Series Jaw Crusher Spare Parts - Buy Jaw Crusher Spare Parts

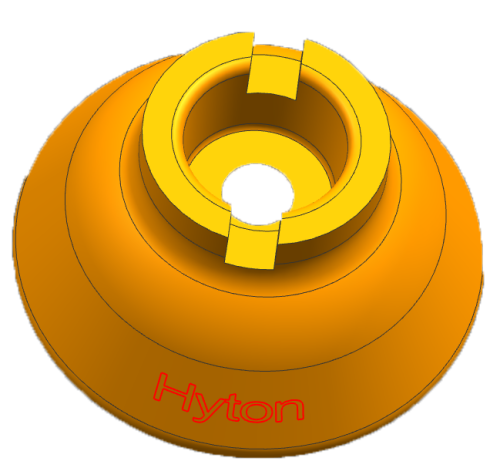

Jaw Crusher Toggle Seat Suit C Series Jaw Crusher Spare Parts Products Description Hyton supplies one-stop service for jaw crusher spare and wear parts, mainly includes: Pitman , Side Plate , Cheek Plate ,Toggle Plate , Flywheel , Wedge , Bearing , Eccentric Shaft, Toggle Plate ,Toggle Plate , Spring , Hopper , End Front and Etc

Learn MoreEngineered for the toughest feed materials ® C Series™ jaw crushers

C Series jaw crushers are based on pinned and bolted, non-welded frame construction. This design principle contributes to their excellent fatigue life and strength, which has been proven in FEM calculations, extensive simulations and in

Learn Morejaw crusher toggle plate design c3054 spring bracket c3054 antec power

Communications with manufacturers of jaw crushers have revealed that no consideration is currently given to force displacement characteristics of the crushed rocks in the design of toggle plate. As a rock tumbles into position it will catch on a comer of a larger diameter and thus will be loaded at two 'points' of contact.

Learn MoreJaw Crusher Wear Parts - Unicast Inc

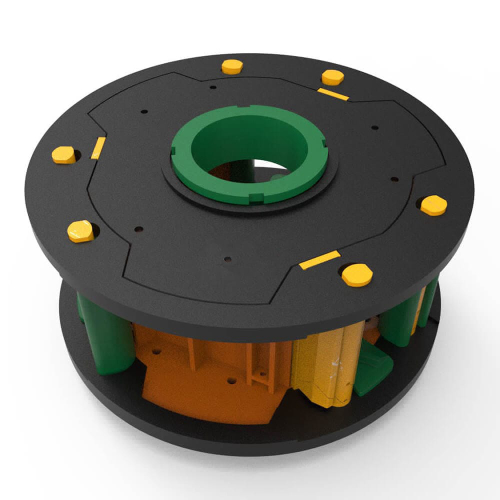

Custom designed to suit your needs, Unicast Jaw Plates and Cheek Plates are engineered to suit the specific Jaw Crusher Toggle Plate Unicast Wear Parts.

Learn MoreA Review on Study of Jaw Plates of Jaw Crusher

7] CAO Jinxi, RONG Xingfu, YANG Shichun, in 2006, Jaw Plate Kinematical Analysis For Single toggle Jaw Crusher Design, College of Mechanical Engineering,

Learn MoreStudy on Liner wear in Single Toggle Jaw Crushers - IJSER

Index Terms—Sliding; jaw liner; single toggle jaw crusher; abrasive wear ing crushing plate design about wear have been neglected by designers [10].

Learn MoreJaw Crushers | McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers. On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavy-duty double

Learn Morejaw crusher toggle plates | crusher bearing requirements

Our jaw crushers are of the single-toggle type and feature a deep, symmetrical crushing chamber, a moving jaw plates. Our CJ crushers have ***** Jaw shim plate is installed instead of the wear plate. 2 JAW CRUSHER SERIES CSS (MM) CJ211 60 110-160 70 120-180 80 135-205 90 150-230 100 160-250

Learn MoreToggle Crushers - SolidsWiki

A Toggle Crusher consists of a set of vertical jaws, one jaw being toggle jaw crushers are constructed of heavy duty fabricated plate

Learn MoreGiant Crushing: Jaw Crusher Parts - Giant Crushing

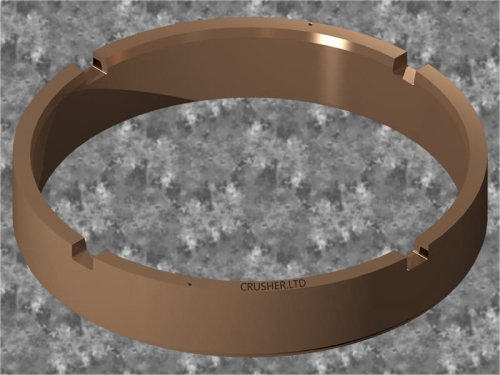

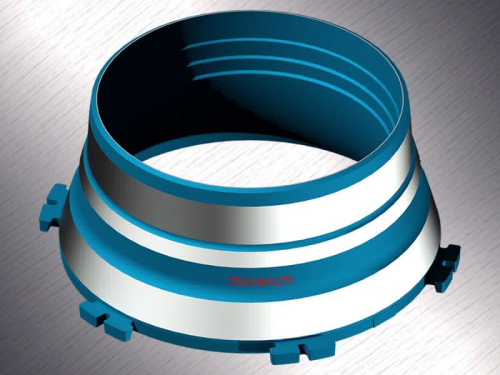

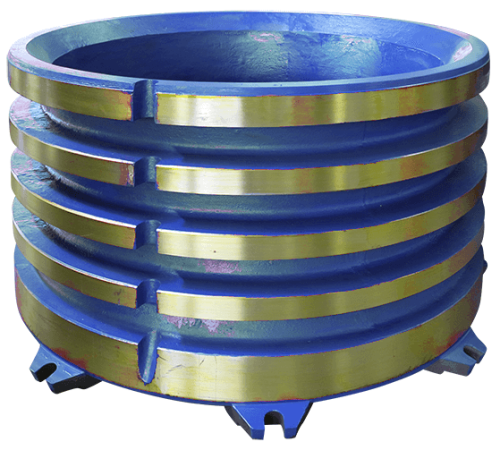

Toggle Seats & Plates Giant manufacture a range of hard wearing toggle seats and plates that can withstand the high demands of mining and rock crushing. Available in several different sizes to suit different cone crushers, Giant toggle seats and plates can handle great crushing pressures and are also designed for easy replacement to minimize

Learn MoreJaw Plates - SHANVIM

JAW CRUSHER PLATE-JAW LINER. Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time. A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw).

Learn Morejaw crusher toggle plate teeth plate / impact crusher liner plate

Counterattack plate breaking hammer is made of high chromium material. Compared with common high manganese steel hammer, it has the characteristics of high hardness, fine discharge and high wear resistance. The high hardness martensite matrix in the hammer can strongly support carbide particles, avoid the carbide falling off from the wear surface during the working process, and ensure the high

Learn MoreWEAR IN STONE CRUSHER PLATE - IJARIIE

There are two types of jaw crushers : single toggle and double toggle crushers. The double toggle Blake machine is considered the original design of jaw

Learn Morejaw crusher toggle plate replacement eccentric bushing mining crusher

Aug 09, · Toggle plate is the most simple and low-cost part of Jaw Crusher, which is usually made by cast iron.It is the driving part of jaw crusher and has three main functions. That is, transmit power, adjust discharge opening and function as a safety device.

Learn MoreTrio® CT2436 Series Primary Jaw Crusher - The Weir Group

These jaw crushers incorporate steeply designed toggle seats which enable efficient crushing at high production rates. They also feature a fixed jaw die

Learn MoreCAD Drafting - Design Upgrade & Update Specialist - Hillsboro

Are you looking for a full-time flexible, mostly work-from-home, AutoCAD & Revit Drafting position? Do you have previous AutoCAD &/or Revit experience & love solving problems adjusting, converting, and maintaining drawings and models in either or both systems? Are you super flexible with your CAD skills and a master at moving drawings and models from one system to another, upgrading & updating

Learn More

Leave A Reply