Single Roll Crusher Working Principle

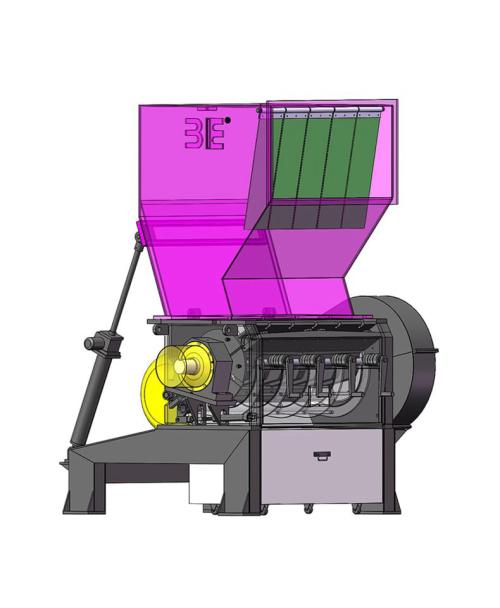

Roll Crushers. A Roll Crusher is massively built; without gears, countershafts, or oil pumps, and with only one moving part. A heavy, annealed, cast steel frame supports the unusually large,

Learn MoreRoll crusher working principle & structure

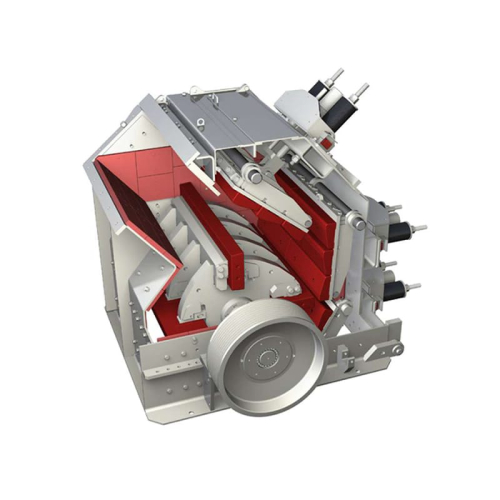

The crushing mechanism consists of a rotating roll 1 and a jaw plate 4. The jaws are mounted on a bolt with a tooth bushing 2 on

Learn Moretypes of crusher machine portable rock crusher socket liner manual pdf

There are four traditional types of crushers in materials engineering. They are known as jaw crushers, gyratory crushers, cone crushers and roll crushers. Types Of Crusher - Working Principles of Crushers. Based on the working principle, crushing machines are divided into the following types: Cone crusher; Jaw crusher; Impact crusher.

Learn MoreStructure And Principle Of Single Roll Crusher

Roll Crusher With stable Performance Fote Machinery. 2021830ensp enspWorking principle of roll crusher The main working parts of the roller crusher is the cylindrical rollers The rollers are supported by the fixed and movable bearings and they are relatively rotating which are driven by the motor. Single Roll Crusher Market Size Share Research

Learn Moreen/single roll crusher introduction.md at main - GitHub

Roll crusher principle working principle for roll crusher double roller crusher working principlehe mode of operation of roll crushers is extremely simple

Learn MoreDouble Roll Crusher - IndiaMART

Deepak Trading Company - Offering Double Roll Crusher, Laboratory Roll Crusher, रोल क्रशर in Jabalpur, Madhya Pradesh. Get best price and read about

Learn MoreSingle Roll Crusher Working Principle Manufacture and Single

Single Roll Crusher Working Principle - manufacturer, factory, supplier from China. Industrial Manganese Steel Jaw Crusher Spare Parts. Well Transported Manganese Steel Jaw Crusher

Learn MoreMechanical structure of roller crusher. - ResearchGate

Roller crusher is widely used in solid and block material pulverizing. Roll gap between the rollers is usually adjusted to satisfy the particle size of

Learn MoreSingle Roll Crusher Working Principle Manufacture and Single Roll

Single Roll Crusher Working Principle - manufacturer, factory, supplier from China. Industrial Manganese Steel Jaw Crusher Spare Parts. Well Transported Manganese Steel Jaw Crusher Spare Parts. Stone Crusher Simple Structure Vibrating Feeder. Wire Rod Plant Rolling Mill Machine.

Learn MoreSingle Roll Crusher Working Principle

Single Roll Crusher Working Principle. 510tpd roller crusher for limestone capused in rot roller crusher a kind of mining machine also known as a double roller crusher which is mainly used to break the ore the roll crusher working principle roller crushersadvantages our engineer will design a specialized production line for customers more

Learn Moreroll crusher construction operating principle

gyratory crushers and smooth-roll crushers It works on the principle of compression. Construction : of schematic diagram operating

Learn MoreRoll Crushers - SolidsWiki

The probable reason is because the large mines require very large crushed product output with minimal cost, makes the roll crusher uncompetitive

Learn MoreWorking Principle Of Smooth Roll Crushers - Stone Crushing

Posts Related to four smooth roll crusher dia 900×700 disadvantages of smooth roll crusher roll crusher working principle and single roll crusher working principle; Click & Chat Now. General introduction of Roll Crushers: – Roll CrushersShanchuan Working Principle of Roll Crushers: (Roll crushers used for minerals and metal ores have smooth faced rolls.) Roll

Learn Moreworking principle of roll crushers

Working Principle of Roll Crusher The main structure of the wheel gearing is composed of fixed roll movable roll drive shaft machine box chassis cover piece and long

Learn MoreSingle Roll Crusher Working Principle In Lesotho

A required crushing process may consist of just one rotor crusher a combination of two rotor crushers a combination of one rotor and one roll crusher or just one roll crusher rotor crushers can treat quite coarse material with maximum inlet size of some 300 300 mm as the typical crushing ratio is 10 at a single stage the material can be.

Learn Moreroller crusher works

2022 1 7 The roll crusher working principle is a physics of angular relations. When the material is too large to pass the rollers, it will not be crushed

Learn MoreHow Single Roll Crusher Work

single roll crusher working principle 2,single roll crusher working principle 2 apteka nawidoku.pl. working of single roll crusher nabestaandeninfo. 2020-12-21 roll crushers slideshare. apr 24, Work Principle Of Roll Crusher

Learn MoreRoll Crusher Working Principle

Single Roll Crushers Mineral Processing Metallurgy. Metallurgical ContentRoll Crushing Action and Working PrincipleDischarge Product of a Roll CrusherOptimal Roll Crusher Feed SizeRoll Crusher CapacityApplications: When to use a Roll Crusher On the right, a Roll Crushers is shown in a sectional elevation o . View Details Send Enquiry Working Principle Of Smooth

Learn Moresingle roller crusher working principle

single roller crusher working principle. May 31, Single Roll Crushers. The Single Roll Crusher, with its 6:1 ratio of reduction, is ideal for reducing large feed lumps to a medium product size while producing a considerably lower percentage of fines. The minimum product sizing of a Single Roll Crusher is generally limited to 2-3".

Learn MoreBubby grandparent - Rooftop cooking Wuppertal

Universal 2436 cast-based roller bearing jaw crusher. which as subject to availability The jaw crusher working principle is when the jaw rises the angle

Learn MoreRoll crusher working.how it work

16/10/ · This crusher consists of,a heavy cast iron frame equipped with two counter rotating rollers mounted on a separate horizontal shaft. The crushed rock from the primary crusher is fed through the gap

Learn MoreSingle Roll Crusher-Products-Ande metallurgical

Single-roll crusher is applied for crushing of fragile and low/medium-hardness material, such as sinter, slag, shale, limestone and etc.

Learn MoreWorking Principle of Crushers - Mineral Processing & Metallurgy

Crusher Working Principle As the head recedes on its opening stroke, the body of material moves downward; until, at the end of the stroke, the plane has moved to position "1." Note that the length of line "1″ from concave to open-side head position, is the same as that of line "O" from concave to close-side head position.

Learn Morecapacity of the single roll crusher

They can be built in large sizes to handle high capacities and run-of-mine large lumps. OPERATING PRINCIPLE The crushing rings on the rotor crush the material

Learn MoreSingle Roll Crusher Working Principle Definition In Reunion

Single Roll Crusher Working Principle Definition In Reunion / the working principle of jaw crushers all jaw crushers feature two jaws one of which is fixed while the other moves. the working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the

Learn Morewhat is the working principle of crusher

2. Crushers' Working Principle (1) Jaw crusher is the crushing equipment that uses two jaw plates to squeeze and bend materials to crush various hardness materials. The crushing mechanism is composed of fixed jaw and movable jaw. The material is crushed when the two jaws are close to each other, and the material smaller than the discharge gate

Learn MoreSingle Roll Crusher Working Principle

Crusher Working Principle And Structure. PE Jaw Crusher - SBM Crusher. Working Principle. PE jaw crusher uses the electric motor as power, through the eccentric shaft the motor pulley, V-belt and pulley driven, the movable jaw according to a predetermined track reciprocating motion, thus will be broken into by the crushing cavity fixed jaw plate, the movable jaw plate and the side plate is

Learn MoreRoll Crushers - ScienceDirect

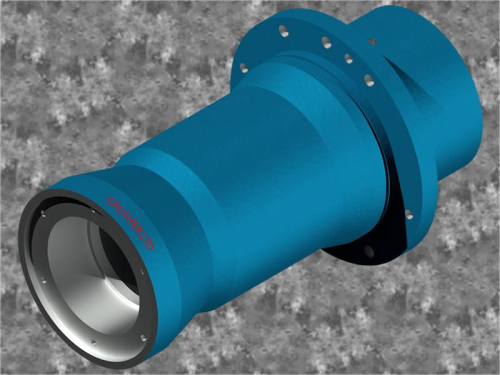

01/01/ · Roll Crusher Geometry. Simplifying Equation (6.1), the radius of the roll is given by (6.2) R = L − d cos θ 2 ( cos θ − 1) Equation (6.2) indicates that to estimate the radius R of

Learn MoreSingle Roll Crusher Principle Pdf - HN droled mine treatment

Roll Crushers Slideshare. apr 24, double roll crusher working principle and structure of double roller crusher 1.this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc. 2.the adjustment of the particle size: between the two rollers equipped with adjustment device like pads or wedge.the wedge .

Learn MoreStructure and Working Principle of Single Roll Crusher

When the single roll crusher works, under the friction force of the rollers and the materials, the materials fed between the two rollers will stick on the rollers with the rotation of the rollers and

Learn MoreSingle Roll Crusher Working Principle-roller Crusher

the single-toothed roller crusher actually combines the jaw crusher and part of the single roll crusher working principle grinding mill equipmentsingle roll Roll Crusher Working Principle Of. roll crusher working principle henan deya. 2012-7-30 double roller crusher working principle. the mode of operation of roll crushers is extremely simple, the

Learn More

Leave A Reply