Cone Crusher Parts - Mineral Processing & Metallurgy

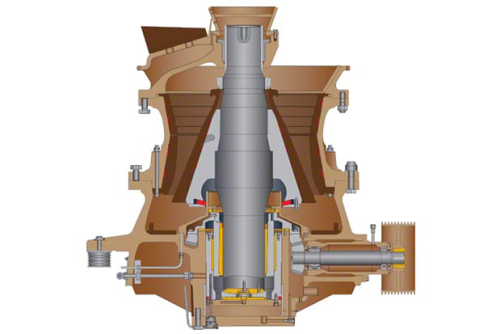

19/02/ · The lubricant is sealed in with a garter type oil seal. Bearings can be lubricated from outside the topshell on the 51, 60 and 84-in. crushers through oil holes in spider caps of the four smaller sizes. Cone Crusher MAINSHAFT. The mainshaft is of high grade forged steel, annealed for stress relief. It is tapered to gauge for head center fit.

Learn MoreCrusher Lubricant™ ISO 220 - Products

D-A Crusher Lubricant™ provides excellent performance in gyratory, cone and jaw crushers. It is also well suited for use in screen gearboxes and bearings

Learn MoreCone crusher maintenance critical to optimum output - Quarry

04/04/ · USE THE CORRECT OIL. The type and condition of your lubrication oil is critical to successful operation of your cone crusher. Crushing with worn out oil or oil of the wrong

Learn MoreCone Crusher Lubrication Oil Manufacture and Cone Crusher Lubrication

Cone Crusher Lubrication Oil - manufacturer, factory, supplier from China. Industrial Manganese Steel Jaw Crusher Spare Parts. Well Transported Manganese Steel Jaw Crusher Spare Parts. Stone Crusher Simple Structure Vibrating Feeder. Iron Ore Slag Rod Mill Crusher Machine.

Learn MoreReasons for the increase in lubricating oil temperature of cone crusher

11/09/ · The lubricating oil in the cone crusher has been used for too long. Under normal circumstances, the lubricating oil replacement cycle is 2000h. If it exceeds 2000h, the lubricating oil viscosity and other indicators will be seriously reduced. Too many impurities in the oil will cause the quality of lubrication to decrease.

Learn MoreCrusher Lubricant™ ISO 150 - Products - D-A Lubricant Company

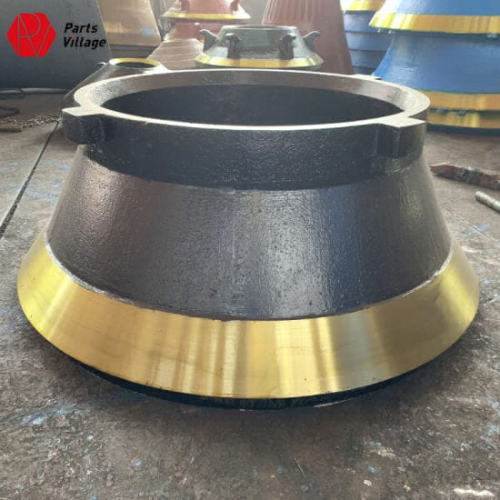

Crusher Lubricant™ ISO 150 D-A Crusher Lubricant™ provides excellent performance in gyratory, cone and jaw crushers. It is also well suited for use in screen gearboxes and bearings requiring EP gear oil lubrication. D-A Crusher Lubricant™ is specially formulated to be compatible with bronze and brass bushings and bearings.

Learn MoreRecommended Lubricant For Cone Crusher

Used Cone Crushers For Sale at Savona Equipment Ltd. CS 2 foot cone crusher. Complete with lube system and electric motor. 1: Crushers - Cone: ID#: 2480 . We will do our best to find what you are looking for.

Learn MoreCrusher | IQ Oil Australia

Crusher ; Client: Minera El Tesoro – Sierra Gorda ; System: Svedala H6000 Cone Crusher, Main Lubrication System ; Oil: 250L ISO 150 ; ISO Prior to CJC®: 18/15/11

Learn MoreNotes of Cone Crusher Lubrication System - Machinery

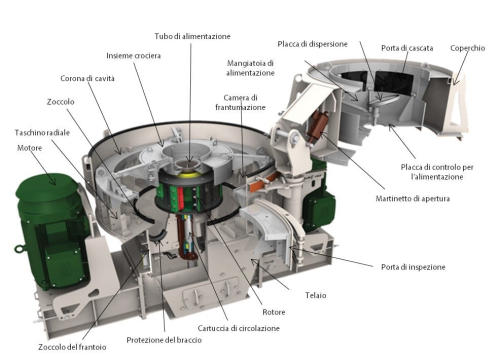

1) The lubricating oil goes into the cone crusher by two paths. One goes in from the bottom oil hole of cone crusher, and then divides into three directions to the inside and outside of the hollow eccentric shaft, the middle oil hole of the main bearing and the bowl type bearing, going through the hole lubricating big and small gear, and then the oil will return from the bottom oil returning

Learn MoreCrusher Lubricant™ ISO 220 - Products - D-A Lubricant Company

Crusher Lubricant™ ISO 220. D-A Crusher Lubricant™ provides excellent performance in gyratory, cone and jaw crushers. It is also well suited for use in screen gearboxes and bearings

Learn MoreWhich Oil Type Used For Lubrication On Crusher -seed

svedala h6000 cone crusher – Gold Ore Crusher. Lubrication Oil Cone Crusher, Svedala. . Main lubrication system Oil volume: 250 L Oil type: ISO VG 150 THE PROBLEM The new generation

Learn MoreCone Crusher Lubrication System

The lubrication system is an indispensable device for each crushing machine to ensure the good lubrication of the equipment and provide the crushing work for the cone crusher. condition. How the lubrication system works. The pressure oil from the lubricating oil station is divided into two paths before entering the cone crusher.

Learn MoreCone Crusher MP1250 - Mobil

Cone Crusher MP1250 · Hydraulic-Hydraulic Power Unit · Frame · Lube System-Main Reservoir · Gear-Drive · Grease Points · Drive Components-Coupling · Bearing · Privacy

Learn MoreThe Common Questions of Cone Crusher and Corresponding

Poor quality of lubricating oil. Poor oil quality will reduce the viscosity of

Learn MoreOil Lubrication For Cone Crusher From Philippines

Crusher Lubricant™ ISO 68. D-A Crusher Lubricant™ provides excellent performance in gyratory, cone and jaw crushers. It is also well suited for use in screen gearboxes and bearings requiring EP gear oil lubrication. D-A Crusher Lubricant™ is specially formulated to be compatible with bronze and brass bushings and bearings.

Learn MoreProper crusher lubrication - Tip of the Week - Lube Talk - Mobil

Oils: As a general rule, operators should use extreme pressure fortified gear lubricants with a minimum viscosity of 22 cSt at the bearing operating temperature. This typically demands an AGMA 3 EP or 4 EP gear oil. The lube oil should operate in a range between 10 and 50 degrees Celsius.

Learn MoreHow does the rock crusher lubrication system work? - Quora

What is the working principle of the Cone Crusher? a common mistake to run an oil-lubricated crusher with contaminated lubricant (used oil, dirty oil).

Learn MoreMethods of preventing oil leakage from spring cone breakers

07/09/2022 · Inspection of Spring Cone Crusher in Production: Regularly check whether the filter is blocked or damaged, and replace the kinked oil discharge pipeline to ensure the smoothness of the oil return pipeline. At the same time, attention should be paid to cleaning the ventilation cover on the side of the drive shaft frame of the spring cone crusher, and use compressed air to

Learn MoreWhat oil should be used for cone crusher? Gear oil or

The multiple cylinder hydraulic cone crusher is equipped with automatic functions such as lubricating oil return flow monitoring,

Learn MoreProper crusher lubrication - Tip of the Week - Lube Talk

29/06/ · There are three main types of crushers – jaw crushers, cone crushers and impact crushers. Jaw crushers: In jaw crushers, a large feed opening receives material. There are two

Learn MoreCone Crusher Oil System, Dust Seal & Thrust Bearing

25/07/ · The second group of crusher components consists of the Cone Crusher’s oil system, the Cone Crusher’s dust seal and the thrust-bearing. The oil system, like the one used

Learn MoreCone Crusher Lube Systems | Crusher Mills, Cone Crusher, Jaw

Lubrication Oil Cone Crusher, Svedala – Offline Oil Lubrication Oil Cone Crusher, Svedala ASIN5031-UK Mining Crushers 12.06. THE SYSTEM Cone crusher H6000 Mark:

Learn MoreMinerals Cone Crusher 1003894081 Lube Oil Filter

Find many great new & used options and get the best deals for Minerals Cone Crusher 1003894081 Lube Oil Filter Element at the best online prices at

Learn MoreHP Series Cone Crusher Lubrication Supplement

The oil temperature in the tank must be a minimum of 16 C (60 F) before the lube pump is started to prevent overloading of pump and motor assembly. However, to

Learn MoreCone Crusher Poor Lubrication Reasons And Solutions

Once the cone crusher is in poor lubrication condition, there will be friction between the lubricating parts and produce lots of heat, which will cause the burn, veneer, and fissure, loosen of surface of bearing bushing and bearing segment. At the same time, the lubricating oil will deteriorate and lose efficacy very soon.

Learn MoreNawa Cone Crusher Me Konsa Oil Lagta Hai

Nawa Cone Crusher Me Konsa Oil Lagta HaiNawa Cone Lubricant Me Konsa Oil Lagta HaiNawa Cone Crusher Oil Ka Nam Keya HaiWelcome to my ChannelSamrat Stone Crus

Learn MoreFive steps to optimize crusher’s lubrication system - Outotec

30/07/ · At minimum, lube system maintenance checks, inspections or servicing must include the following steps: 1. Monitoring of lube oil temperature. A lot can be learned about a cone crusher by simply watching the supply oil temperature and comparing it to the return oil temperature. Return oil temperature should be in the range of 60~140ºF (15~60ºC

Learn MoreHow to do the lubrication of the cone crusher_Jiaozuo Zhongxin Hevy

This system can be lubricated before the crusher is started. It is a highly adaptable and easy-to-control system to control the lubrication system oil temperature, oil volume and oil pressure to ensure the normal operation of the lubrication system and the crusher Work is very important. The oil temperature of the lubricating oil of the crusher

Learn MoreCrusher Lubricant™ ISO 150 - Products - Gear Lubricants - D-A Lubricant

Crusher Lubricant™ ISO 150. D-A Crusher Lubricant™ provides excellent performance in gyratory, cone and jaw crushers. It is also well suited for use in screen gearboxes and bearings requiring EP gear oil lubrication. D-A Crusher Lubricant™ is specially formulated to be compatible with bronze and brass bushings and bearings.

Learn MoreSolutions of Lubrication Fault for Cone Crusher - Luoyang Dahua

Today, we will talk about the solutions of lubrication fault of cone crusher. High temperature of lubrication oil. 1. The cooling fan does not work; 2. The heat dissipation of cooling fan is bad; 3. The inner parts are burnt; 4. Safety valve invalid. Low lubrication oil flow. 1. The oil filter is blocked; 2. The suction capacity of oil pump

Learn MoreCone crushers CH/CS CH430 - Kroon-Oil

Which oil is best for your Cone crushers CH/CS CH430? Complete professional advice, including motor oil, gearbox oil (transaxle) and lubricants for the power steering system, brake

Learn More

Leave A Reply