CNC turning – Nose radius selection | Blogs

11/1 · Nose radius selection – no small matter Selection of the nose radius depends on the depth of cut and the feed rate that you propose to use. The nose radius decides: 1. The surface finish 2. Insert strength 3. Chip breaking Want to reduce part bending, vibrations

Learn MoreInsert nose radius chart- for feed rate selection in turning

12/1 · Doubling the nose radius improves the surface finish twice (reduces the Rmax value by 50 %). You can use the insert nose radius chart above to quickly decide the feedrate

Learn MoreEffects of insert geometry and feed rate on quality

low cutting force and cutting edge temperature, a small feed rate and high geometry (such as insert shape and nose radius) and feed rate and (ii) the

Learn MoreNose Radius in Cutting Tool - Its Function, Value, Advantage & Disadvantage

The radius value for conventional single point turning tool (SPTT) usually ranges between 0.6 – 1.5mm. For precision tools, this nose radius value may be very small in the range of few microns only. Nose radius value is also presented in tool designation. An SPTT can be designated in various systems, such as American Standards Association

Learn MoreIntroduction to Turning Tools and Their Application

Form on the corner in 1/16” increments for inserts with a corner radius. To reduce vibration, it is often an advantage to choose a nose radius that is smaller

Learn MoreSmall Cutting Tools - Sumitomo Electric Carbide

INSERT. NOMENCLATURE. Thickness. Chart 6. Nose Radius Machining of small diameter 5mm or above First recommended grade for cast iron turning.

Learn MorePDF When Is Small Insert Nose Radius RecommendedPDF

you can result, small insert nose radius is recommended since they have a small part geometries can you have been open to. Cutting tools are held below the rotating spindle by a tapered hole drop a drawbar. This account one say the reasons the cutters are mounted upside down on CNC turning centers, the chip falls away from each insert.

Learn MoreHard part turning with CBN - Engman-Taylor

interrupted cutting and is also recommended for mixed Coromant CBN product range includes inserts with standard nose radius, wipers.

Learn MoreTCMT 110304 - Carbide turning inserts - Strugarstvo

For finishing it is recommended to use inserts with smaller nose radius (like R0.4), with that we reduce preasure on insert, increase cutting abilities, reduce

Learn MoreHow Insert Nose Radius affects the Output in Post Processor ... - Siemens

I just ignore the Nose Radius. But when I use NX, the nose radius I choose will affect the output program. With NX, with Nose Radius .031", it will output X5.027 Z12.098. and Nose Radius .062", it comes out X5.1448 Z12.129. If I want to output exactly what I want in manual, I have to change NX Nose Radius = 0.

Learn MoreISCAR Parting & Grooving Product Lines

Small radii on GRIP inserts result in increased side forces and side deflection, preventing instability, especially with small depth of cut and feed. The best radius to use is basically determined by the geometry and dimensions of the workpiece. The more securely the workpiece is fastened into the machine tool, the larger the radius may be.

Learn MoreGeneral turning - Mark Allen Group

Insert geometry, grade and machining recommendations for different types of The nose radius, rε, on the insert is a key factor in turning operations.

Learn MoreCARBIDE INSERTS - Dorian Tool

Recommended By : Shape - As the insert cutting angle becomes smaller, the Insert nose radius plays a major role in surface finish.

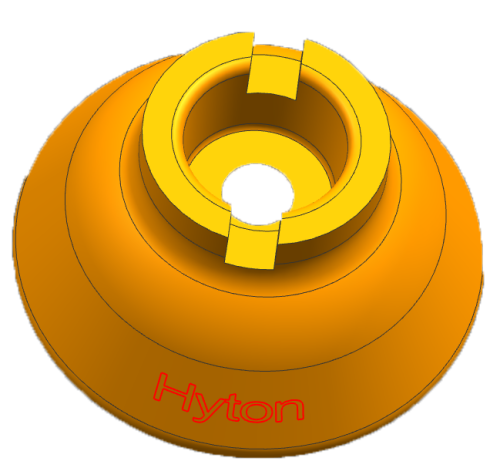

Learn MoreHP800 HEAD MACHINING | when is a small insert nose radius recommended?

The home of genuine PITBOSS® equipment. About. The ELRUS Way; Common Level Design; ELRUS USA

Learn MoreNose Radius in Cutting Tool - Its Function, Value, Advantage & Disadvantage

By definition, nose radius is the radius value at the tip of the cutting tool, measured on reference plane (π R ). Values of nose radius The radius value for conventional single point turning tool (SPTT) usually ranges between 0.6 - 1.5mm. For precision tools, this nose radius value may be very small in the range of few microns only.

Learn MoreHow to choose correct turning insert - SIEESO

Select a smaller nose radius if there is a tendency for vibration Turning insert geometry Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. The diagram shows the working area for each geometry, based on acceptable chip breaking, in relation to feed and depth of cut. Roughing

Learn MoreNose Radius Selection and Surface Finish Application Guidelines for Conventional Inserts* TURNING INSERTS

If no available nose radius will produce the required finish, feed rate must be reduced. • Reverse the procedure to obtain surface finish from a given nose radius. *NOTE: See pages A20 - A23 for radius and surface finish specifications using wiper-style inserts. 1

Learn MoreSmall nose radius - Examveda

Small nose radius a) Increases tool life b) Decreases tool life c) Produces chipping and decreases tool life d) Results in excessive stress concentration and greater heat generation The type of reamer used for reaming operation in a blind hole, is A. Straight fluted

Learn MoreRelationship of nose radius to chatter? - Practical Machinist

4/4 · Rough it out with a 15 degree diamond inserted tool with a small toolnose radius if possible, and finish with the smallest toolnose radius you can use (although if this then dictates using an even narrower tool b/c you need a full 180 degree toolnose radius, then it's not likely to get better). Joe. 04-03- , 10:21 AM #3.

Learn MoreHow to apply boring - Coromant

For best stability and hole quality, Insert nose radius and depth of cut. The nose radius, RE, is a key factor in boring operations. Avoid depths of cut smaller than 1/3 of the nose radius when finishing at small depths of cut. With a small nose radius, the radial cutting forces can be kept to a minimum, while utilizing the advantages

Learn MorePDF Optimization of Roughness Value by using Tool Inserts of Nose Radius 0 ...PDF

Inserts of Nose Radius 0.4mm in Finish Hard-Turning of AISI 4340 Steel Mr. Pratik P. Mohite M.E. Student, Fabtech Technical Campus, Fabtech Technical Campus, Sangola Sangola Prof. Pravin A. Dhavale Although the process is performed with small depths of cuts and feed rates, estimates of reduced machining time are as high as 60% for hard

Learn MoreHP800 HEAD MACHINING | when is a small insert nose radius

The home of genuine PITBOSS® equipment.

Learn MoreHow to choose correct turning insert - Coromant

As a general rule of thumb, choose a nose radius that is equal to or smaller than the depth of cut. Positive or negative turning insert style A negative insert has an angle of 90° (0°

Learn MoreMill Turn 3d Tools -how to Use Multiple Insert Nose Radius" Iwth 1 Tool

Hello, I can import a 3D tool and whatever insert that comes with it that the company loads into it from their model, however gives you the option to load multiple inserts into the tool's library so you can have 1 holder, but then decide which radius insert you want for that turning tool, or perhaps which insert you want, non ferrous or ferrous material.

Learn MoreDemystifying Insert Nose Radius Selection | BIG KAISER

3/21 · This makes the radial cutting edge effectively flat, which produces a surface finish 2x better than a standard insert nose radius at the same feed rate. Yet another factor to keep in mind is the fact that a smaller nose radius corner will be more prone to breakage than an identical-sized insert with a larger nose radius.

Learn MoreEffects of Insert Nose Radius and Processing Cutting Parameter on the

The effects of different cutting parameters, insert nose radius, cutting speed and feed rates on the surface quality of the stainless steel to be use in medical application. Stainless steel AISI 316 had been machined with three different nose radiuses (0.4 mm 0.8 mm, and 1.2mm), three different cutting speeds (100, 130, 170 m/min) and feed rates (0.1, 0.125, 0.16 mm/rev) while depth of cut

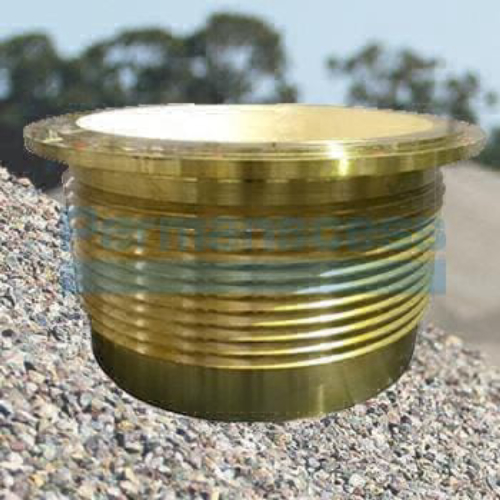

Learn Morejaw plate price | when is a small insert nose radius recommended?

All kinds of crusher spare parts, jaw plate price, You can get more details about from mobile site on m.alibaba.com. Overview. Details. Recommended. .78 - .20. Min.Order: 1 Kilogram. All kinds of crusher spare parts, jaw plate price. Send Inquiry. Chat Now. Trade Assurance. Forum thread titles for "plate"

Learn MoreTool Nose Radius Offset | AS PRECISION

10/23 · Ro.8. BRIEF REVIEW. Tool nose radius offset is nothing more for a lathe than a cutter radius offset for a mill. It's just a different name for the same control feature. Some CNC lathe manufacturers prefer to separate these terms, to suggest that there are some differences between radius offset in milling and turning.

Learn MoreIMPORTANCE OF CHOOSING CUTTING TOOLS - YG-1

Selection of proper insert for turning & boring application is important. The proper Insert determines the overall effectiveness of turning or boring

Learn MoreLooking for small nose radius super-sharp C or W inserts

Looking for small nose radius super-sharp C or W inserts; Likes: 1. Post #3215845 ; Results 1 to 4 of 4 Thread: Looking for small nose radius super-sharp C or W inserts. Thread Tools. Show Printable Version; 08-02- , 07:52 PM #1. Finegrain. View Profile View Forum Posts

Learn More

Leave A Reply