Virtual machining of spiral bevel gear - ZHY Gear

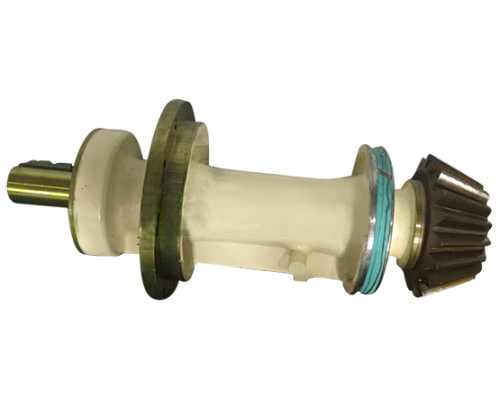

According to the basic parameters of spiral bevel gear in Table 1, the wheel blank is established in CATIA 3D software. The ordinate of point ① is the crown top distance, α Is the face cone angle, l is the tooth face width, and point ③ is the face cone point.

Learn MoreSurface Geometry of Straight and Spiral Bevel Gears

01/12/1987 · The parametric representations of the spherical involute and the involute spiraloid, which are the tooth surface geometry of straight bevels and spiral bevels, respectively, have been derived in

Learn MoreDesign of key parameters and establishment of model of spiral bevel

According to the geometric parameters of the gear blank, the tooth full height of the big end of the spiral bevel gear to be machined can be calculated: Referring to the existing specifications of cemented carbide finger milling cutter in the market, the commonly used model with a total length of 55 and a blade length of 15 is Φ 6 * 15 * 50

Learn MoreBevel Gear - IQS Directory

A spiral bevel gear is the most complex form of bevel gear. The teeth of spiral gears are curved and oblique, in contrast to the teeth orientation of

Learn MoreWhat is a Bevel Gear and How does it Work? | Linquip

02/05/ · Spiral bevel gears present a great level of monitoring over the way in which teeth mesh, and their structure allows for special mounting deflections without extremely increasing the force on either end of the teeth. They can be employed at high velocities, and are typically used in bicycle and motorcycle gears. Read More On Linquip

Learn MorePDF Spiral-Bevel Gear Noise: An Approach to Solving In-Field IssuesPDF

non-generated gear spiral-bevel gearset is used to validate the approach. While the pinion convex tooth flank could mesh at different torque levels without undue noise up to 3,400 rpm, the pinion con-cave flank exhibited significant noise at around 1,400 and 3,200 rpm. The spiral bevel gear modeling soft-ware was used to calculate new pinion

Learn MoreBevel Gears - Configure and purchase - MISUMI

JIS B 1704 grade 3 spiral bevel gear. Module m1.0 / 1.5 / 2. Volume Discount. 2D / 3D CAD data available.

Learn MoreNews - Hypoid Bevel Gear Vs Spiral Bevel Gear

Spiral bevel gear, the axes of the driving and driven gears intersect at one point, and the angle of intersection can be arbitrary, but in most automobile drive axles, the main reducer gear pair is arranged vertically at a 90° angle the way.

Learn MoreDifference Between Straight Bevel Gear and Spiral Bevel Gear

For same material, size and tolerance, spiral gears are 1.2 - 1.5 times costly than straight bevel gears. Cost difference increases when gear size is small due to difficulty in manufacturing. High finishing requirement may also lead to broader price difference. Thrust force: Two mating gears always exert force on the bearings that mount the shafts.

Learn MoreHome - spiral gear

Spiral bevel gears are bevel gears with helical teeth positioned in a 90-degree angle. The teeth are designed with a slight curve to provide better flexibility and traction. Although they can be

Learn MoreIndustrial Applications of Bevel Gears - Bevel Gears (India) Pvt. Ltd

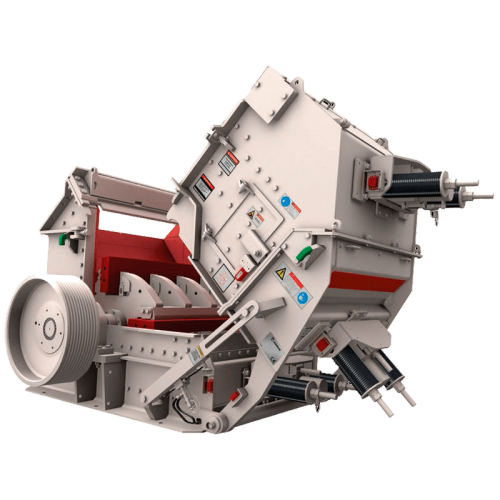

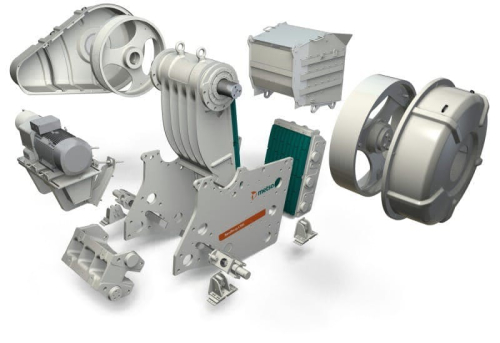

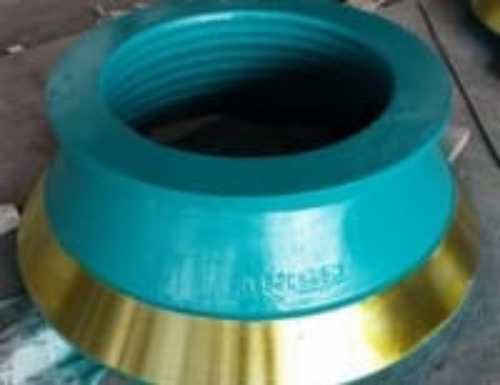

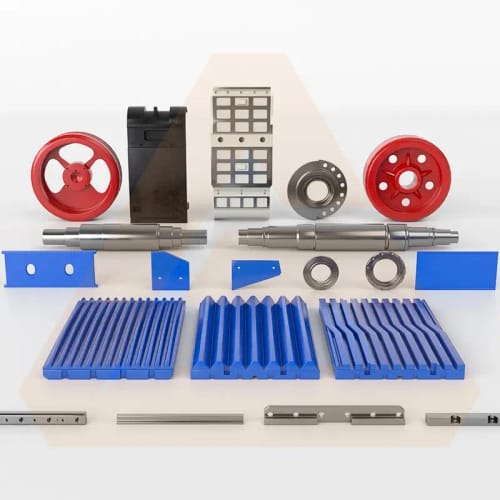

High speed straight and spiral bevel gears 16,000 rpm jet application Special steel and processes Air Pre-heater Straight bevel gears for pre-heater gearboxes. Cement Mills Lapped and hard cut options Reverse engineering options Cone Crushers & Sand Mixers Engineering design assistance available Straight, spiral or skew bevel options

Learn MoreSpiral Bevel - 3-d Gear Models and Software

Spiral Bevel Gear program description. Microsoft Excel program with VBA macros. Input gear data into Excel. Run macros to generate IGES file of the tooth surface. Use the IGES to cut teeth on your gear blank in CAD. This program generates tooth surfaces for spiral bevel gears commonly known as Gleason and Klingelnberg. Two programs: for Gleason

Learn MoreSpiral Bevel Gears - Ondrives

Spiral Bevel Gears & Pinions ground manufactured on the Gleason 280G in closed loop (Gleason GEMS ® Design -Ground-Measured and closed loop to maintain the

Learn MoreWest Leyden High School Apparel Store - Rokkitwear

Most Popular. West Leyden High School apparel store featuring high school sports apparel, spirit wear, and clothing. Show your spirit and support your favorite sport and school. Every purchase of official, licensed apparel and fan gear supports West Leyden High School. Shop www.rokkitwear.com for ALL of your school's official merchandise!

Learn MoreSpiral bevel gear | KOHARA GEAR INDUSTRY - MiSUMi

Spiral bevel gear from KOHARA GEAR INDUSTRY. MISUMI has more than 9 millions products of Automation Components, Fastners and Materials.

Learn MoreWhy Choose Spiral Bevel Gears?

Spiral bevel gears are bevel gears whose axes intersect, often at a 90-degree angle. The teeth are cut with a slight curve along their

Learn MoreSpiral Bevel Gears | Spiral Bevel Gear Manufacturers & Suppliers | Best

Spiral bevel gears are designed for long life and are made of durable aluminum alloy housing. They can be manufactured from a variety of different materials. Spiral bevel gears can be further classified according to the manufacturing process. Some are made using the Gleason method, which features zero inclination of the arc and midpoint.

Learn MoreSpiral Bevel Gear manufacturers & suppliers

China Spiral Bevel Gear manufacturers - Select 2022 high quality Spiral Bevel Gear products in best price from certified Chinese Gear,

Learn MoreSpiral Bevel Gear

Spiral Bevel Gear is our major product, it's a bevel gear with helical teeth, its vibration and the noise is lower than conventional straight bevel gear.

Learn MoreCustomizable Precision Spiral Bevel Gear Industrial Bevel Gear

China Customizable Precision Spiral Bevel Gear Industrial Bevel Gear, Find details about China Sprocket, Worm Gear from Customizable Precision Spiral Bevel Gear Industrial Bevel Gear - Qingzhou Jianfu Gear Co., Ltd.

Learn MoreGlobal Spiral Bevel Gear Boxes Market Report 2022 - SWOT Analysis and

The Spiral Bevel Gear Boxes market research study is a comprehensive and intelligent evaluation tool as well as a valuable resource that will assist you in establishing a strong position in the

Learn MoreGears near Northlake, IL | Better Business Bureau. Start with Trust

Showing: 9 results for Gears near Northlake, IL. Sort. Distance Rating. Filter (0 active) Filter by. Serving my area. Get Connected. Get a Quote. Distance. All distances < 5 Miles < 10 Miles < 25

Learn MoreStraight, Skewed, and Spiral Bevel Gears - Overton Chicago Gear

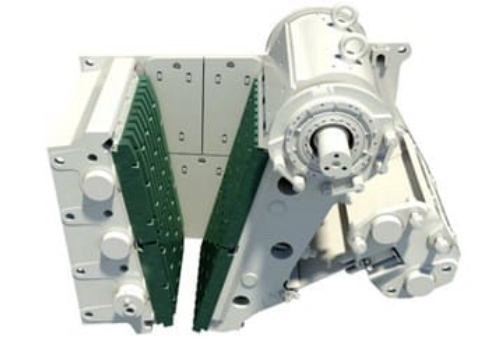

Overton Chicago Gear is a major manufacturer of high precision bevel gearing, including spiral bevel gears, spiral bevel hard cut gears, skewed bevel gears, and straight bevel gears. We make bevel gearing up to 100-inch diameter on conventional machines. We produce all types to 160-inch diameter with 5-axis milling machines.

Learn MoreOEM - helical-bevel-gear

Spiral bevel gears are commonly utilised in automotive gears, development tools, and a assortment of industrial purposes. Hypoid bevel gear. The Hypoid bevel equipment is comparable to the spiral bevel equipment but differs in the condition of the enamel and pinion. The smallest ratio would outcome in the cheapest gear reduction.

Learn MoreMinimizing Noise and Backlash With Spiral Bevel Gear Drives

As a refined type of right-angle drive, a spiral bevel gear drive is an important part of your motion control system. Transferring power throughout your manufacturing system for food processing, agriculture, textile, packaging, military, material handling, and marine applications, these critical components move force at a 90-degree angle.

Learn MoreCalculation example of spiral bevel gear tooth surface

The inspection results are shown in FIG. 10. It can be seen from Fig. 10 that the shape, size and contact path direction of the contact area are basically consistent with the tooth surface contact analysis results of spiral bevel gear (Fig. 2), and the meshing quality of the gear pair is good, which verifies the correctness of this method.

Learn MoreHow To Use Bevel Gears | KHK

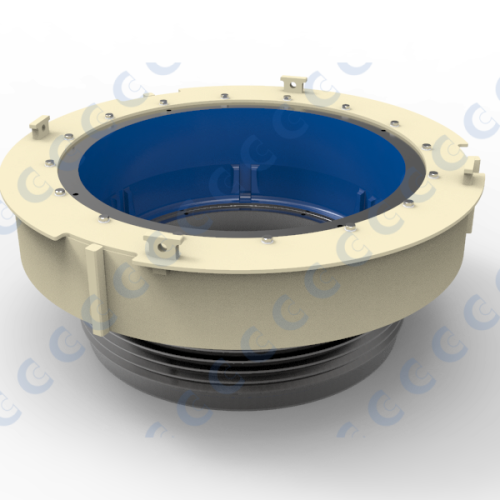

When installing MBSA or MBSB spiral bevel gears produced in B7 style (ring gear), always secure the gears onto the mounting base with taper pins to absorb the rotational loads. It is

Learn MoreDirection of thrust and rotational forces in a spiral bevel gear

The precise mathematical model for the tooth surface and transition surface of spiral bevel gears is derived. Taking a pair of spiral bevel gears of a heavy

Learn MoreHigh Precision Spiral Bevel Gear Bevel Pinion And Crown Wheel For Gearbox

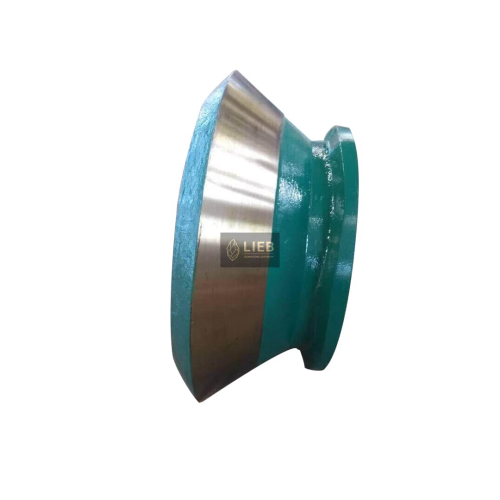

High quality High Precision Spiral Bevel Gear Bevel Pinion And Crown Wheel For Gearbox from China, China's leading Spiral Bevel Gear product market, With strict quality control Spiral Bevel Gear factories, Producing high quality High Precision Spiral Bevel Gear Bevel Pinion And Crown Wheel For Gearbox products.

Learn MoreSturdy spiral shaft bevel gear for Manufacturing Machinery

Spiral Shaft Bevel Gear (702 products available) 1/6

Learn MoreBEVEL GEARS – KG STOCK GEARS

Spiral bevel gears have their teeth formed along spiral lines. They are somewhat analogous to cylindrical type helical gears in that the teeth are angled;

Learn More

Leave A Reply