Thread: Troubleshooting Jaw Crushers - bulk-online Forums

Jaw Crusher common troubleshooting methods · 1) Replace the eccentric shaft, correct lifting host · 2) replacement of the eccentric shaft, the

Learn MoreMini Jaw Crusher | Sepor, Inc

SEPOR, INC. 718 N FRIES AVE. WILMINGTON, CA 90744. 310 830 6601. Fax: 310 830 9336 [email protected]. OPERATING AND MAINTENANCE MANUAL. MINI JAW CRUSHER

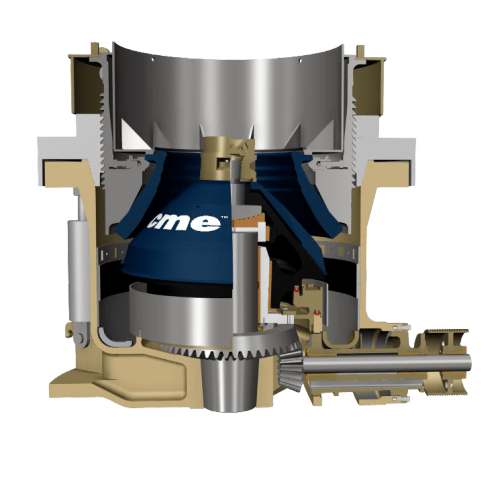

Learn MoreTroubleshooting Cone Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

CAT Crushers Jaw Crusher Model PE 200×300 Please feel free to give your inquiry in the form below. We will reply you with details ASAP. E-mail: * Tel: Machine: * Message: ← Previous Next → Troubleshooting Cone Crushers Crushers troubleshooting

Learn MoreWhat Are Major Problems In Jaw Crusher?

Solutions to problems of the jaw crusher. Jaw Crusher Bearing Temperature Limit and Failure Solution Jaw crusher is the main ore or stone crushing plant in sand industry. Thus fever

Learn MoreJaw Crusher common troubleshooting methods - Heavy Industry

Troubleshooting: 1) removal of nesting material inlets to ensure the smooth flow of materials 2) tighten the belt or replacement of the triangular 3) to re-install or replace the bushing tight set 4) transfer of the voltage is the workplace to meet the requirements of the host operating voltage 5) the replacement of bearings. 2.

Learn MoreProblems In Jaw Crushers - HN droled mine treatment equipment expert

5565 jaw crusher problems - Grinding Mill China. SBX cone crusher accepts COMPANY SOLVES ROCKY PROBLEM midsize jaw crushers models 1021 Thru 3042 model 3258 troubleshooting,

Learn MoreRegular crusher maintenance integral to reliability, performance and

Checking the air filter to ensure the crusher is vented properly and that unwanted contaminates are not entering the breather Checking the strainer basket on a cone crusher ensuring that there are no signs of excessive wear or damage to internal components Greasing bearings if required to ensure proper lubrication and cooling of those bearings.

Learn MoreJaw Crusher Model I PULVERISETTE 1 classic line / Downloads

FRITSCH Jaw Crushers: pre-crushing of very hard, hard, medium-hard, brittle, tough, Operating manual Jaw Crushers PULVERISETTE 1 classic line.

Learn MoreMasih Dalam Pembongkaran Jaw Crusher Pc 200 6 Part 2

2022/9/13 · masih dalam tahap pembongkaran mesin jaw yang trouble.#excavators #alatberat

Learn MoreElimination of Common Faults in Jaw Crusher

When the jaw crusher run or non-crushing into the crushing chamber, it is easy to cause the brackets to break, this time should replace the brackets and control

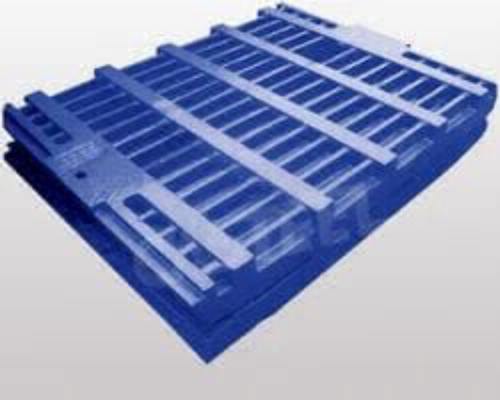

Learn MoreCrusher Wear Parts Reference Guide - Corporation

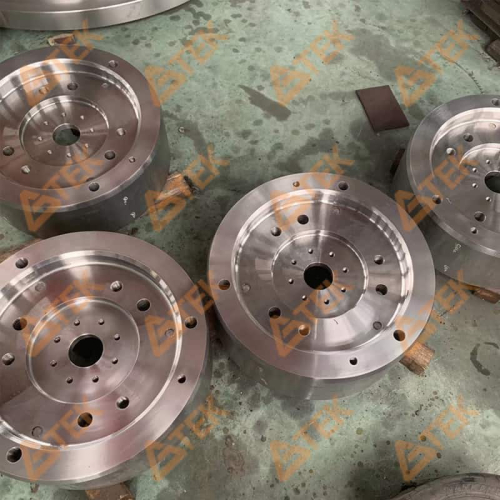

This Guide has been developed to help Dealers personnel to expand their crusher tools E.G. Jaw liners are subject to numerous pressure and impact

Learn MoreCrusher Trouble Shooting | Crusher Mills, Cone Crusher, Jaw

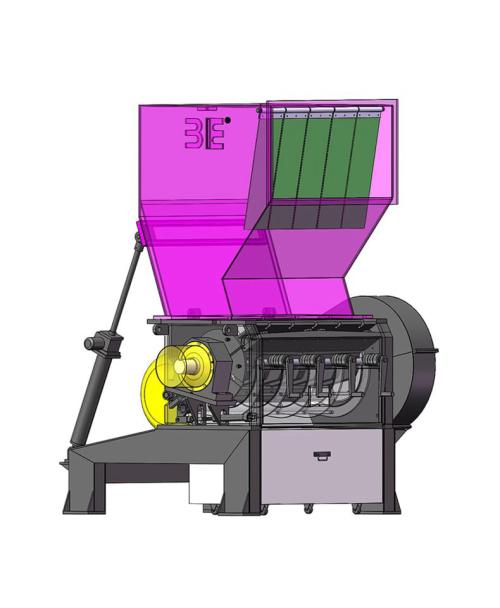

Impact Crusher Troubleshooting Solutions: There are many common faults of the Impact Crushers, so a solution is also different, Yuanhua mechanical failure to crushing plant

Learn MoreCommon Faults and Solutions of Jaw Crusher

11/22 · Solution: there might be three reasons about this problem. Firstly, the undersize of the discharge opening causes the clashes of fixed jaw plate and movable jaw plate, which

Learn MoreRepairing and Troubleshooting for Jaw Crusher (II) - Luoyang Dahua

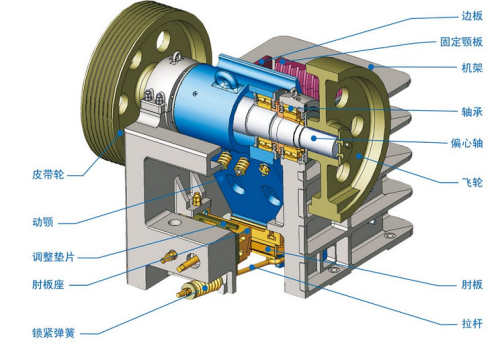

The large type of jaw crusher could be recovered to the operational performance by overhauling if necessary. The repair contents of jaw crusher are as follows: (1) Clean and inspect the eccentric shaft and bearings, usually the eccentric shaft and bearings should be cleaned once every 6-8 months and be replaced when the clearance of rolling

Learn MoreMethods of Jaw Crusher Troubleshooting (2)_ZK Ball Mill_Rotary Kiln

Method of troubleshooting. 1) Replace or increase jaw crusher. 2) Replace the motor wiring. 3) Adjust the discharge port opening to the nominal discharge port in the specification and increase the jaw crusher for crushing. 4) Check the size of tooth plate and tooth pitch, if not meet the standard must be replaced jaw plate.

Learn MoreCrusher Problems Troubleshooting | Crusher Mills, Cone Crusher, Jaw

5565 jaw crusher problems - Grinding Mill China. 5565 jaw crusher problems. Posted at: August 6, 2012. troubleshooting, and a comprehensive review of new automation, lubrication and

Learn More20+ Common Faults of Jaw Crusher with Solutions | M&C

20+ Common Faults of Jaw Crusher with Solutions · 1. Bearing Damage · 2. The Bearing Temperature is Too High · 3. Lining Plate Fracture · 4. Elbow Seat Eorn · 5.

Learn MoreCrusher Problems Troubleshooting | Crusher Mills, Cone

troubleshooting cederrapids cone crusher troubleshooting cederrapids cone crusher. and to move from site to site without the problems 200 HP (149 kW) 45" (1143 mm) high

Learn MoreMethods of Jaw Crusher Troubleshooting (2)_ZK Ball Mill_Rotary

Methods of Jaw Crusher Troubleshooting (2) Publication date: 2016-12-15 16:20 article source: ZK Corp viewed: ZK is one of Chinese professional jaw crusher manufacturers, with more than 60 years’ design and production experience of jaw crusher.

Learn MoreJaw Crushers Troubleshooting

Regular crusher maintenance integral to reliability Aug 08, With jaw crushers, if you allow the jaw dies to move during operation they can cause damage to the frame of the jaw crusher. Similarly, loose liners in cone crushers may damage the head or bowl. It is

Learn MoreCause Analysis and Problems Solving of Jaw Crusher

The temperature of the bearing seat or the movable jaw plate is too high · bearing is lack of the oil or the oil is injected too much. · oil hole

Learn MoreConstruction, Working and Maintenance of Crushers for

This information will help to achieve increased reliability at a decreased cost. Material crushed in an impact crusher is an example of dynamic impact.

Learn MoreFault and troubleshooting Method of Jaw Crusher (1

11/28 · Previous Article:Fault and Troubleshooting Method of Jaw Crusher (2) Next Article: Luoyang Dahua at bauma China Luoyang Dahua Heavy Industry Science & Technology Co., Ltd. Add. : No.280, Guanlin Road, Luoyang, Henan, China Follow Us :

Learn MorePDF Crushing - KPI-JCIPDF

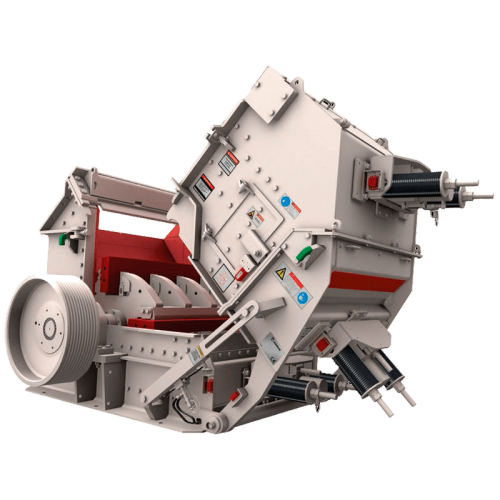

Pioneer Jaw The Pioneer Series from Kolberg-Pioneer, Inc. represents the very latest in jaw crusher technology. Engineered to be the highest capacity jaw crusher on the market, the Pioneer Jaw Crusher will deliver up to 25% more tons per hour than other comparable jaw crushers. Pair that with heavy-duty flywheels for reduced horsepower

Learn MoreLMC100D JAW CRUSHER USER MANUAL - Laarmann Group

LMC100D JAW CRUSHER MANUAL. Page 3. 1. Description. 3. The LAARMANN laboratory Jaw Crusher is a robustly constructed single-toggle type with one fixed jaw

Learn MoreHow to improve jaw crusher performance and productivity

Why it is a problem? Bridging can cause a significant loss of production that oftentimes goes unnoticed. It is relevant to keep an eye on

Learn MoreTroubleshooting Cone Crusher Problems

Related to problems faced in jaw crusher. vibrating SCREEN TROUBLESHOOTING. MVP-type cone crusher structure is significantly different from traditional cone 5565 jaw crusher problems - Grinding Mill China

Learn MoreEight common faults and solutions for jaw crusher

The reason for the above situation is: the pull rod and pull rod spring of jaw crusher are damaged. At the same time, if the elbow plate has

Learn MoreCommon Troubleshooting of Jaw Crusher – Luoyang Dahua

9/18 · In this text, we will talk about troubleshooting of jaw crusher Solution for common problems of jaw crusher: 1. Replace or increase the number of crusher. 2. Change the wire connection. 3. Adjust the discharge opening to the specified nominal discharge size and

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

2022/7/20 · How to replace jaw crusher plates? Inspection and maintenance of other parts Check whether the discharge port is blocked, remove the blockage in time, and keep the discharge unobstructed. Check whether the V-belt is loose. If it is too loose, you need tight it because loose belt will cause slippage. Whether the eccentric shaft is blocked.

Learn More

Leave A Reply