All Corporation catalogs and technical brochures - DirectIndustry

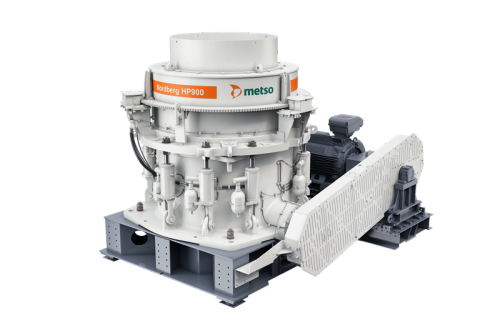

Search in Corporation catalogs and technical brochures on DirectIndustry and find the information you need in 1 click. Exhibit with us {{>currencyLabel}} ® GP7™ Secondary Gyratory Crusher Brochure. 2 Pages. ® GP330™ Cone Crusher Brochure. 3 Pages. ® GP220™ COne Crusher. 3 Pages. ® HP5™ Cone

Learn MoreGyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

thyssenkrupp gyratory crushers represent today's state-of-the-art. They are designed for high performance and, at the same time, cost-effective operation, i.e. low servicing and maintenance costs. Gyratories and jaw type gyratory crushers as an integral part of semi-mobile and stationary processing plants are used for primary crushing of bulk

Learn MoreExpect results - Metallurgist & Mineral Processing

always start the crusher correctly •verify that the tank oil temperature is between 86°f (30°c) and 90°f (32°c) •start the lube pump and circulate the oil •start the crusher drive motor and allow

Learn MoreAll Automation catalogs and technical brochures - DirectIndustry

SUPERIOR® gyratory crushers. 12 Pages. Primary gyratory stations. 9 Pages. PNEUMATIC CYLINDER ACTUATORS, SERIES B. 20 Pages. Process Capacity IPS. 6 Pages. Slurry Hose System. Jamesbury Manual Gear Actuators. 6 Pages. Automation Valvcon V Series Actuator 115VAC and 230 VAC. 8 Pages. Jamesbury Valvcon V Series Actuator 115VAC

Learn MorePDF Crushing and Screening Handbook - AusIMMPDF

the crusher and scalp out fi nes. Primary gyratory crushers - ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers - we have more installed jaw crushers than anyone in the world. The lead-ing choice due to their high reduction ratio and heavy duty design. Cone crushers - capacities available to suit all

Learn MorePDF Expect results - Metallurgist & Mineral Processing EngineerPDF

always start the crusher correctly •verify that the tank oil temperature is between 86°f (30°c) and 90°f (32°c) •start the lube pump and circulate the oil •start the crusher drive motor and allow the crusher to come to full speed •run the crusher with no load (empty) until the return oil temperature is above 65°f (18°c) •start feeding the crusher

Learn MorePDF 2. GYRATORY CRUSHERS - Metallurgist & Mineral Processing EngineerPDF

ratory crusher, and short-shaft gearless gyratory crusher. The gyratory crusher, whether used as a primary or secondary. is essentially a gravity-type machine. Material flows vertically from top to bottom. It receives a large coarse feed, usually run-of-mine, and its product normally requires additional crushing before produc- ing the final

Learn MoreTecman Rock Breaker - H-E Parts International

Pedestal type or radio remote control. Proportional hydraulic control for precise operation. Application specific designs. 100kg through to 7 tonne hammers. Tecman rock breaker booms are designed to offer ease of installation and perfect operational geometry. Tecman rock breaker booms increase safety and production.

Learn MoreQH441-OperationManual - Crusher Works

39 Item Part No. Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)

Learn More60X89 gyratory crusher part | gyratory crusher manual

Superior™ MKIII Series primary gyratory crushers. Superior™ MKIII primary gyratory crushers have new sets of shells and concaves, which have been implemented after countless hours of research and development. The improvements to the Outotec Outotec Superior™ MKIII crushers brings up to 70% reduction in downtime. Crusher maintenance

Learn MoreC120 jaw crusher parts database and search tooling

C120 jaw crusher - cncrusher.net. 42-65,50-65,54-75,60-89,60-110 Svedala MK-II Primary Gyratory Crusher. And wear spare parts for other common

Learn MoreSuperior™ MKIII Series primary gyratory crushers

Outotec's Superior™ MKIII primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation.

Learn MoreGyratory Crusherer - Gravel And Sand Making

Dec 05, · 2. GYRATORY CRUSHERS The original patent for the gyratory crusher was granted to Phile- tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co. At

Learn Mores new generation of crusher upgrades aim to increase

The new upgrades are available for and cone crushers, and Superior gyratory crushers. They are offered in packages that are

Learn Moreid/gyratory crusher c series english pdf.md at main - GitHub

gyratory crushers table C125 crushers gyratory crusher foundation designs pharma consultant C series jaw crusher Manual SlideShare

Learn MoreCrusher Manuals

Some Mobile Crusher Tractor Manuals PDF above the page – , Nordberg. Corporation ‘s distribution network consists of 300 representative offices in more than 50 countries. The company employs about 30,000 people. 1886 Bruno establishes Manufacturing Co. in the United States for the production of

Learn MoreGyratory Crusher Pro | manufactor | thyssenkrupp Mining

thyssenkrupp gyratory crushers represent today’s state-of-the-art. They are designed for high performance and, at the same time, cost-effective operation, i.e. low servicing and maintenance costs. Gyratories and jaw type gyratory crushers as an integral part of semi-mobile and stationary processing plants are used for primary crushing of bulk

Learn MoreCrushers - All crusher types for your reduction needs - Outotec

Gyratory crushers have an oscillating shaft. The material is reduced in a crushing cavity, between an external fixed element (bowl liner) and an internal moving element (mantle) mounted on the oscillating shaft assembly. The fragmentation of the material results from the continuous compression that takes place between the liners around the chamber.

Learn MoreC'Series Spares & Replacements

For ® C'Series Jaw Crusher parts & spares contact CMS Cepcor. We can provide replacement parts on a range of ® Jaw Crushers.

Learn More54X75 gyratory crusher part | used head bush for cone crushers

54X75 gyratory crusher part | ch430 cone crusher manual pdf. c63 front end c63 C80 BRNG HOUSING C80 c63 2020. z172 o-ring bottom seal (shaft jaw crusher partshot sales jaw crusher piston shaft plate machine parker o-ring size chart. AGGREGATE SOURCES CAN BE GROUPED INTO THREE MAIN AREAS:

Learn More60X89 gyratory crusher part | hp cone crusher main shaft bushing

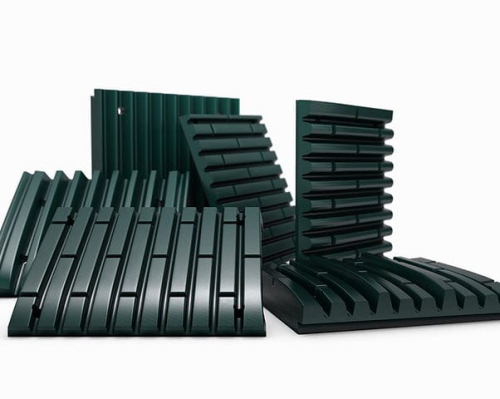

A gyratory crusher consists of a concave sur-face and a conical head; both surfaces are typically lined with manganese steel. The top. introduces a new range of crusher wear parts. is expanding its crusher wear part offering by launching a new for ® HP Series™ and GP Series™ cone crushers as well

Learn MoreCrushing and Screening Handbook - AusIMM

the crusher and scalp out fi nes. Primary gyratory crushers – ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers – we have more installed jaw crushers

Learn MoreCrusher Maintenance Manual - potentintelligent

Crusher Maintenance Manual 11/6/ superior gyratory crusher 54 X 75 maintenance manual heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry.

Learn Morecrusher pdf | crusher spare head bushing supplier in saudi arabia

gyratory crushers. SUPERIOR® gyratory crushers - Automation - PDF May 22, · 4265 Gyratory Crusher A crusher is a machine designed to reduce large rocks into smaller rocks, gravel diamond crusher mumbai eccentric bushing list of atto vertical roller mill z036 lamp mw9y12 foshan chinese crusher machine spare

Learn MoreGyratory Hydraulic Cone Crusher

Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1]. The smaller form is described as a cone crusher. The larger crushers are normally known as primary crushers as they are designed to receive run-on-mine (ROM) rocks directly from the []

Learn Morecrusher handbook pdf | cr seals by size

C120 jaw crusher with its 1 200 x 870 mm (47 x 34") feed opening provides excellent capacity even in the toughest applications. The hydraulic drive ensures trouble-free operation and enables crusher direction to be changed in case of blockage. The totally new Caterpillar C13 engine module provides optimal power to the high inertia

Learn MoreHigh Efficiency Ore Gyratory Crusher For Mining Plant

Aug 30, · Crusher Machine, Cone Crusher, Steel Slag Crusher manufacturer / supplier in China, offering High Quality and Low Price Gyratory Crusher for Mining, Cylinder Stone/Sand/ Aggregate Washing Machine (YTX1530), High Efficiency Spring Cone Crusher Granite and so on.::: Mining Machine Vertical Shaft Rock Stone Impact Crusher Description of Impact

Learn MoreSUPERIOR® gyratory crushers - Automation - PDF Catalogs

Minerals Industries, Inc., 20965 Crossroads Circle, Waukesha, WI 53186, USA, tel +1 262 717 2500, fax +1 262 717 2501, www.metso.com SUPERIOR Gyratory Crushers Brochure 2012.indd 2 It is the attitude we share globally; our business is to deliver results to our customers, to help them reach their goals. Open the catalog to page 12

Learn MoreSUPERIOR® gyratory crushers - PDF Catalogs | Brochure

SUPERIOR gyratory crushers are built to help you meet the challenges of highcapacity primary crushing. With thousands of units operating in mines and

Learn MoreMining crushers SuperiorTM MKIII Primary Gyratory

s line of SuperiorTMPrimary Gyratory crushers are designed to meet the demand for high efficiency and high capacity mining installations. Superior™ MKIII is the first high speed

Learn MoreJAW CRUSHER LT 95 Workshop Service Repair Manual

JAW CRUSHER LT 95 Workshop Service Repair Manual. JAW CRUSHER LT 95 Workshop Service Repair Manual. Call Us (00) 000 111 222 JAW CRUSHER LT 95 Workshop Service Repair Manual All / JAW CRUSHER LT 95 Workshop Service Repair Manual. JAW CRUSHER LT 95 Workshop Service Repair Manual. 2 sold in last 8 hours

Learn More

Leave A Reply