Jaw Crusher | manufactor | thyssenkrupp Mining Technologies

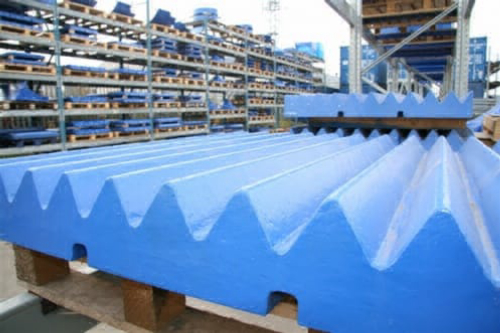

Jaw crushers are used within the aggregates, cement, and mining industry, as they have been proven to be an efficient primary crusher for hard rock materials such as granite and others. The mining and cement industry also profit off their optimized crushing chamber. thyssenkrupp Mining Technologies jaw crusher types

Learn MoreGyratory Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

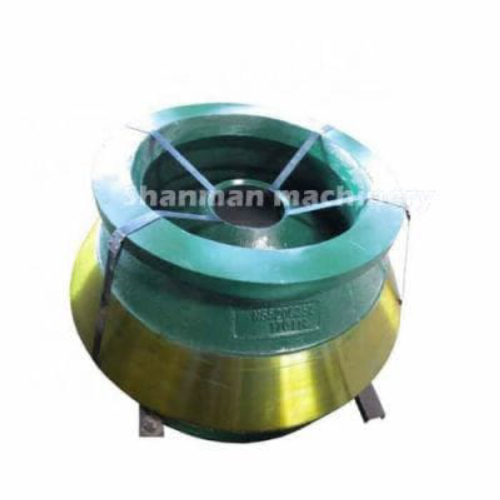

gyratory crusher ( jrtr krshr ) ( mechanical engineering ) A primary breaking machine in the form of two cones, an outer fixed cone and a solid inner erect, Gyratory Crusher Parts,Gyratory Crusher Offers Manufacturers,

Learn MoreGyratory Crusher HOW IT WORK | Crusher Mills, Cone Crusher, Jaw Crushers

Gyratory crusher,primary gyratory crushers maintenance,working if you have used Gyratory Crusher of questions,gyratory crusher sizing how gyratory crusher works - Crusher South Africa how a gyratory crusher works | Crusher Solutions Gyratory and cone crushers work in pretty much the same way, although they have slightly

Learn MoreGyratoryn Crusher Sketch | Crusher Mills, Cone Crusher, Jaw Crushers

gyratory crusher technical data. . CGM machinery designs the reasons why CGM hammer crusher technical drawing. Gyratory Crusher Jaw Crusher Hammer Crusher . Chapter 5. Gyratory and Cone Crusher - Ebook Downloader. Sketch of a Gyratory Crusher (Crusher size is designated by the gape and mantle diameter). 130 Fig. 5.2.

Learn MoreGyratory Crusher Pro - thyssenkrupp Mining Technologies

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally

Learn MoreCompare Gyratory Crusher vs Jaw Crusher - Mineral Processing & Metallurgy

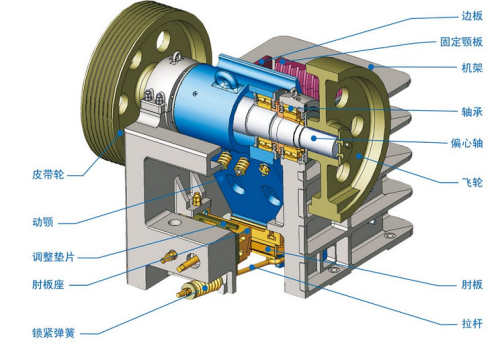

Jaw and gyratory crushers are heavy equipment and are not used extensively in the food industry. In a jaw crusher, the material is fed in between two heavy jaws, one fixed and the other reciprocating, so as to work the material down into a narrower and narrower space, crushing it as it goes.

Learn MoreCE Africa | Crusher Equipment - JAW / CONE / GYRATORY CRUSHERS

CE Africa | Crusher Equipment - JAW / CONE / GYRATORY CRUSHERS 011 568 8324 [email protected] Impact Crusher CE Africa MNP Series Impact Crushers could be able to run in the coarse and middle-fine size mining crushing plant .

Learn MoreWhat Type of Crusher Is Best for Primary Crushing?

Types of Primary Crushers · Gyratory Crushers · Jaw Crushers · Hammermills · Horizontal Shaft Impact Crushers · Sizers · Roll Crushers · Cone Crushers

Learn MoreJaw Crusher - an overview | ScienceDirect Topics

The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 1.5 m (for the largest equipment). – This crusher can handle products with a Mohs hardness that is not necessarily less than 5. – As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concaves.

Learn MoreThe Features and Differences between Jaw Crusher and Gyratory Crusher

02/09/ · d. It is required to feed the ore with a uniform particle size, otherwise the crusher is easy to be blocked, and the miner must be set before crushing. e. It is suitable for crushing massive ore, and sometimes the discharge particle size is too large for strip or flake ore. (A jaw crusher works in Morocco's 500tpd silver ore dressing plant)

Learn MoreGyratory Crushers - Mineral Processing & Metallurgy

The action of the gyratory crusher, and of the other member of the reciprocating pressure family, the jaw crusher, is fundamentally a simple one, but as will be seen a great deal of thought and some very progressive engineering has been expended upon the design of crushing chambers to increase capacities and to permit the use of closer discharge

Learn MoreJaw Crusher VS Gyratory Crusher - Luoyang Dahua

Comparison of performance advantages of gyratory crusher and jaw crusher. The outstanding advantage of the gyratory crusher is that the crushing wall is large, which can reach -9.5, and sometimes it can be as high as 13.5. The production efficiency is high, and the work is relatively stable. Either side can feed ore and can be crowded with ore.

Learn MoreComparison of gyratory crusher and jaw crusher

The gyratory crusher is continuously broken, so the productivity is high, the crusher works more smoothly, the energy consumption is lower, and the product particle size is more uniform. The disadvantages are the high level of the machine, the complexity of the organization, the cost of manufacturing and repairing, the large investment in

Learn MoreCrusher Wear Parts For Jaw, Cone, Impact, VSI, and Gyratory Crusher

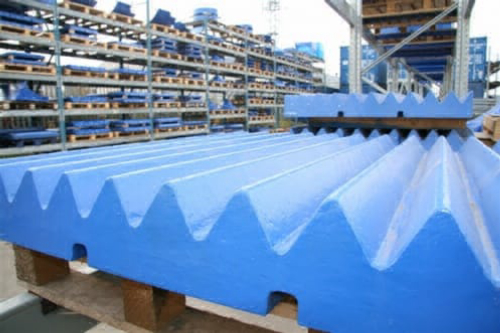

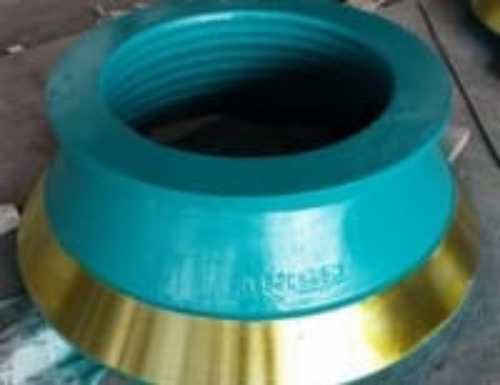

Qiming Machinery is a leader crusher wear parts foundry in China, which manufactures jaw, cone, impact, VSI, and gyratory crusher wear parts for all popular brands. Our product engineers are problem-solving specialists, designing crushing surfaces to handle oversize material, break up slabby material, and reduce recirculation.

Learn MoreDH Gyratory Crusher | Crushing/Grinding

DH Gyratory Crusher' Unique crushing chamber provides large capacity and large crushing ratio.

Learn MoreWhat Are the Differences Between 7 Types of Crushers?

The particle shape produced by gyratory crusher is not as well as that produced by jaw crusher. But the

Learn MoreCrushers - All crusher types for your reduction needs - Outotec

The disadvantage of this type of crusher, when high capacity is required, is the relatively small discharge width, limiting the capacity as compared with the discharge circuit of a gyratory crusher. Jaw crushers are mainly used in plants producing up to approximately 1600 t/h. Primary crushing with gyratory crushers

Learn MoreThe comparison between Gyratory Crusher with Jaw ... - PRLog

here we will make a difference between jaw crusher and gyratory crusher. 1.The crushing of gyratory crusher is continuously, so gyratory

Learn MoreWhat is the Difference between Jaw Crusher and Gyratory Crusher, and

Different shape and structure, (1) Jaw crusher has the advantages of simple structure, low manufacturing cost, small machine height, easy configuration, convenient maintenance and so on. (2) The gyratory crusher has complex structure, high fuselage and large volume, which requires a higher workshop.

Learn MoreJaw Crushers for Mining in Canada - Nelson Machinery Equipment

Jaw Crushers for Mining in Canada - Nelson Machinery Equipment Category: Crushers Home / Shop / Crushers 1 2 3 4 8 9 10 → Showing 1-16 of 158 results ID: N0762 2″ X 6″ STURTEVANT LAB JAW CRUSHER Sold ID: C1365 2.5″ X 4″ BICO LAB JAW CRUSHER ID: C1151 2.75″ X 5.5″ ATLAS LAB JAW CRUSHER ID: N00002 2.75″ X 5.5″ ATLAS LAB JAW CRUSHER ID: C1528

Learn MoreCrusher - Wikipedia

Jaw crushers: Soft to very hard: No limit: Dry to slightly wet, not sticky: 3/1 to 5/1: Heavy mining, quarried materials, sand & gravel, recycling Gyratory crushers: Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary

Learn MoreDifference Between Jaw Crusher and Gyratory Crusher - JXSC

The gyratory crusher is continuous crushing. Its outstanding advantage is high productivity, the ratio of crushing is big, up to 6-9.5. Some of the crushing ratios can reach 13.5, and the work is smooth, vibration is small. Jaw crusher is intermittent crushing, crushing efficiency is relatively low.

Learn MoreCompare Gyratory Crusher vs Jaw Crusher

The Jaw crusher is the smaller of the two and its single feed point will make it a logical choice for underground workings. In the actual

Learn MoreGyratory Crusher | Hazemag North America

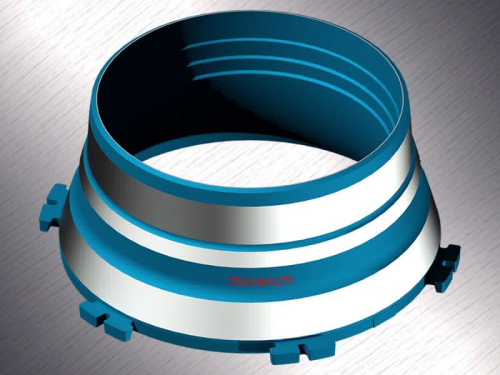

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the

Learn MoreJaw Crusher Manufacturer | CITIC HIC

Crushers · Gyratory Crusher · Jaw Crusher · Semi-mobile Gyratory Crushing Station · Single-cylinder Cone Crusher · Multi-cylinder Cone Crusher.

Learn MoreChoosing the Right Rock Crushing Equipment - Amcast

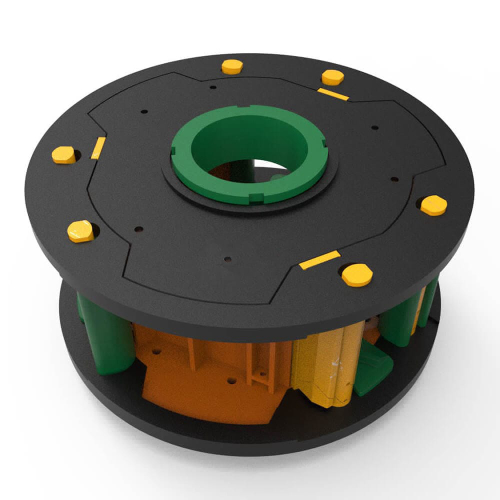

A gyratory crusher consists of a concave surface and a conical head constructed from heavy steel casting. It works by using a mantle that

Learn MorePDF 2. Gyratory CrushersPDF

jaw and gyratory crushers. Manufacturers redesigned their gyratories to reduce the feed opening, decrease the closed-side setting, and in- The gyratory crusher has been built in three types known respec- tively as the suspended-spindle, the supported-spindle and the fixed- spindle type. The second type, with the hydraulic piston as the sup

Learn MoreGoing underground: Jaws or a primary gyratory?

Above 1,000 tph, primary gyratory crushers begin to look interesting, and after the throughput reaches 2,000 tph, jaw crushers are very rare, with the

Learn Moreen/jaw crusher vs a gyratory crusher.md at main - GitHub

The jaw crusher is not so efficient a machine as the gyratory crusher described in the next paragraph,the chief reason for this being that its

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

20/07/2022 · Unlike gyratory crushers, the main lubrication used in jaw crushers is grease instead of oil. When using grease, there may be several different ways to inject it into the necessary lubrication points. It can be operated manually with a grease gun, an oiler or metering pump. Video of automatic lubrication system of a jaw crusher

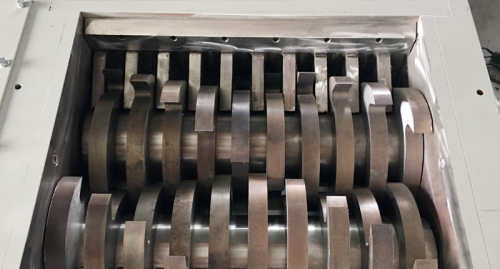

Learn MoreType of crushers and their difference - JXSC Mining

10/12/ · Jaw crusher is used as primary crusher, it’s reduction ratio is usually 6:1. It uses compressive force to break the material, this mechanical pressure is achieved by the two jaws of the crusher. Similar to a jaw crusher, the gyratory crusher pulverizers the stones by placing them between two manganese steel plates and going straight down

Learn More

Leave A Reply