Crusher Maintenance Mechanic - Salt Lake City, UT Job in Salt Lake City

Crusher Maintenance Mechanic - Salt Lake City, UT. CRH Americas Materials Salt Lake City, UT Full-Time. Apply on company site. Job Details Company Overview. favorite_border. Job ID: 432479.

Learn MoreCrusher Maintenance Mechanic Jobs, Employment

Crusher Maintenance Mechanic - Salt Lake City, UT. Staker Parson Companies 3.3. Salt Lake City, UT 84116 +7 locations. Thorough mechanical knowledge of crusher and related equipment. This is a skilled position involving maintenance and operation of company conveyor and crushing

Learn MorePreventive crusher and screen maintenance - Outotec

Fully utilizing the latest preventive crushing and screening machine maintenance technology can help save aggregates production business owners big money annually. After all, crushers and screens are critical assets that keep their businesses running smoothly and efficiently. ® ST3.5™ mobile screen.

Learn MoreCrusher & Plant Maintenance Pty Ltd | Mining & Quarry Plant

2013. 9. 13. · We are a Mining Maintenance Company Specialising in: Grinding Mills & Crusher Maintenance; Rotating Equipment Laser Alignment Maintenance – Crusher & Plant Maintenance Solutions Pty. Ltd. Crusher & Plant Maintenance provide maintenance services and repairs for all makes and models of rock crushers and screens.

Learn MoreRock Crusher Maintenance - HHMG

2021. 8. 26. · Rock Crushers are no different. There are three types of maintenance that one must follow to properly maintain the crusher. They are – Preventive maintenance, Predictive maintenance and Reactive maintenance. Preventive Maintenance. This type of crusher maintenance plan need to be on a schedule and followed to keep up the crusher life.

Learn MoreRoll crusher installation, operation and maintenance

2021. 8. 23. · 2. Maintenance of the roll crusher. (1) Roll crushers require frequent maintenance of the roll surface while in operation. (2) Smooth roll crushers are sometimes equipped with grinding wheels on the frame, so that when the roll surface is worn out with pits or grooves, the roll surface can be repaired by grinding on the machine without removing

Learn MoreAvoid Unplanned Downtime: 5 Crusher Maintenance Best Practices

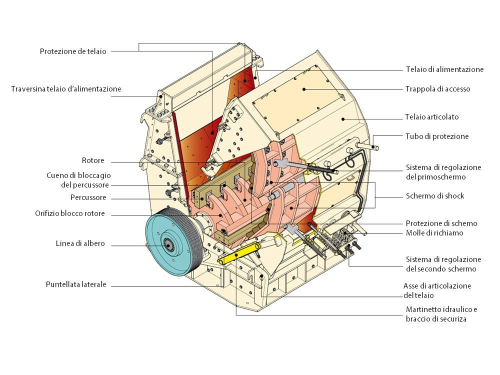

That is why it is number one on my list of tips for crusher maintenance," says Schmidt. Daily visual inspections on HSI crushers include monitoring key wear parts of the crusher, such as the rotor and liners, as well as benchmark items, such as coast down times and amperage draw.

Learn MoreCrusher Service | Maintenance & Servicing | CMS Cepcor

regardless of the manufacturing brand, application and operator maintenance schedules, it has to be considered that crushers have an arduous life and it is the nature of the beast that crushers will likely suffer from unplanned breakdowns that can be expensive to repair - whether caused by component fatigue failure, lubrication or uncrushable

Learn MoreQH441-OperationManual - Crusher Works

2015. 11. 6. · 39 Item Part No. Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)

Learn MoreJaw and Impact Crusher Maintenance - RR Equipment

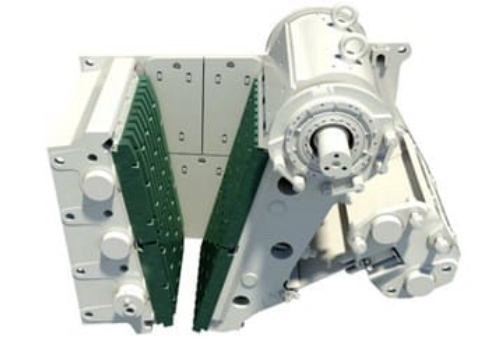

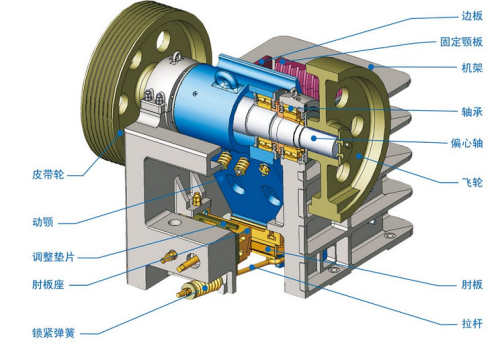

I would say that in general, yeah, there's definitely some maintenance involved with crushing. Typically we're looking at the wear parts or the actual parts of the crusher that are impacted by the material. So if it's an impact crusher it would be the blow bars. If it's a jaw crusher it's the jaw dies or jaw plates.

Learn More4 Types of Stone Crushers' Maintenance and Efficient Improvement

Why are preventive and predictive crucial to crusher maintenance? Preventive means that by making regular checklist and inspections to keep crushers in good condition. Maintenance checklist is usually set up on a daily (8 hours), weekly (40 hours), monthly (200 hours), yearly (2,000 hours). Only doing that, can you prolong the machine's life

Learn MoreJaw Crusher Maintenance and Inspection - Luoyang Dahua

2018. 10. 16. · The maintenance and inspection of jaw crusher mainly focus on below aspects: (1) Check the temperature of the bearing. The temperature of bearing shall not over 60 ℃ (antifriction bearing temperature shall not over 70℃). Since the bearing is made of alloy, which is properly working under 100℃, if the temperature is over 60℃, please stop the machine and

Learn MoreConstruction Working and Maintenance of Crushers for

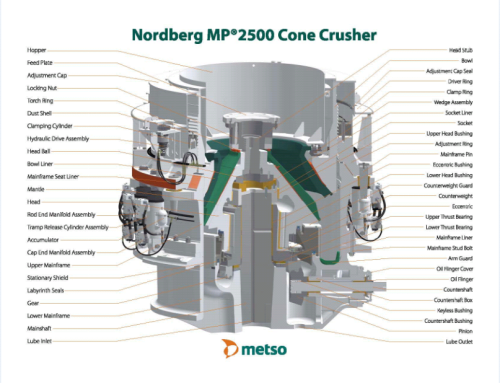

2018. 12. 26. · 5 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials www.practicalmaintenance.net In a non-reversible hammer mill with screen bars, shown in

Learn MoreChina Crusher Maintenance Manual Manufacturers, Factory

Description crusher maintenance manual The crusher spare parts is the main crusher maintenance manual, most of the maintenance of the crusher is to replace and maintain the spare parts. We can offer jaw crusher spare parts for C series C80,C96,C106,C116,C120,C130,C150,C160,C200,

Learn MoreCoal Crusher Maintenance Manual

roll crusher maintenance manual mining - Grinding Mill China. Single Roll Crusher capacity for Gold ore,Coal, coke, 2007 PowerCrusher - 1310I Impact Crusher: Crusher Maintenance & Instruction Manual.

Learn MoreCrusher services - Outotec

Crusher maintenance and repairs Implementing a preventive and predictive maintenance program is a key factor to extending or maximizing your crusher performance. Proper maintenance doesn't only help extend crusher life, but it allows you to optimize your parts supply, manpower scheduling, and repair work. Preventive crusher maintenance

Learn MoreCRH plc Crusher Maintenance Mechanic - Salt Lake City, UT Job in Salt

Crusher Maintenance Mechanic - Salt Lake City, UT. Salt Lake City, UT. $45,177 - $64,263 (Glassdoor est.) Apply Now. Save. Job. Job ID: 432479. Staker Parson Companies, a CRH company, is a member of the CRH West Division; Our purpose, commitment to the future, and formula for growth is to champion the safety, empowerment, and development of our

Learn MorePDF Construction Working and Maintenance of Crushers for Crushing Bulk ...PDF

Operating the crusher with a completely filled crushing chamber. Choking Stoppage of the flow of material through the crusher, which is usually due to the wet and sticky material clogging exit points. Circulating Load The amount of oversize material returned back to the crusher from a screen in a closed circuit crushing system.

Learn MoreMaintenance of Material Handling Equipment | Crushers | Conveyors

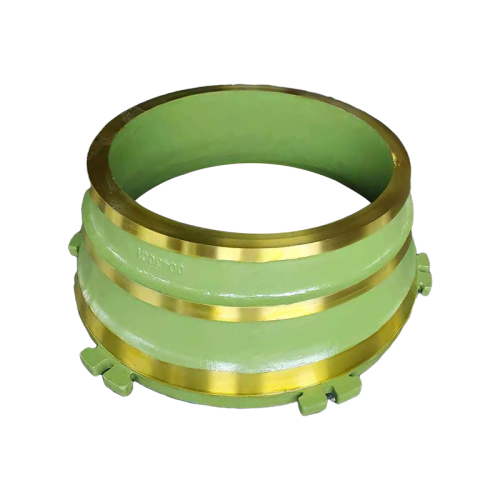

Due to abrasion and general wear from regular operations, these liners break down over time and need to be replaced on a regular basis. In fact, changing out manganese (the industry short-hand term for replacing the crushing chamber liners) is one of the most important regular maintenance items that crushers require. Manganese changes

Learn MoreParts 48′ Gyradisc upper liner | maintenance of vertical roller

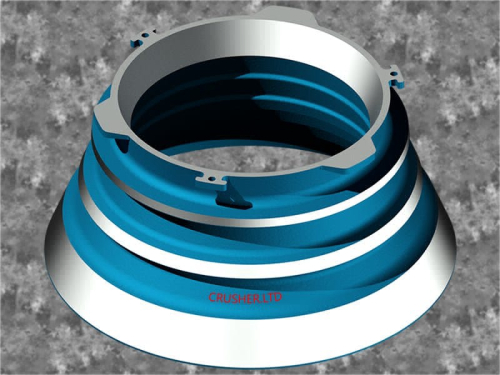

Lockpost Seal For Cone Crusher. Our high quality crusher parts are made for the HP Crusher 300 and 400 series, Gyradisc Crushers 36 48 54 66, and 2 3 4 4.25 5.5 7 Cone Crushers. Symons. For more than 100 years, the ® brand of forming systems has stood as the preferred system for concrete forming around the globe.

Learn MoreCrusher inspections - Outotec

Undetected issues can lead to poor crusher availability, increased repair costs, HSE problems, unplanned downtime and production losses at your production plant. Having regular inspections as part of your maintenance plans, is key to the extension or maximization of your crusher's performance!

Learn MoreCrusher Maintenance Supervisor Jobs, Employment

Plant Maintenance Supervisor GOLDEN QUEEN MINING COMPANY LLC Mojave, CA 93501 Estimated $53.3K - $67.5K a year Full-time This includes a jaw crusher, cone crusher and high pressure grinding roll crusher as well as chutes, conveyor belts and associated equipment. Posted 30+ days ago · More

Learn MoreCrusher maintenance services

Close examination and good maintenance of your crusher protects your plant's overall productivity. By acting fast, you can avoid poor performance, stoppages and costly repairs. Our regular crusher inspections and ongoing technical support ensure your equipment keeps operating at maximum efficiency.. In addition to these comprehensive inspections, our crusher maintenance services include

Learn Morejaw crushers operation and maintenance manual pdf

Home. jaw crushers operation and maintenance manual pdf. Welcome to the mining equipment production base. We mainly produce crushing, grinding and related mining equipment. If you have any needs, you can contact our online customer service or leave a message through the form below. We will serve you wholeheartedly!

Learn MoreCrusher Maintenance Jobs, Employment

1,161 Crusher Maintenance jobs available on Indeed.com. Apply to Operator, Maintenance Technician, Maintenance Mechanic and more!

Learn MoreCrusher Equipment Service, Maintenance & Machining

The trusted OEM-authorized choice to Service ALL makes and models of crushers *60 years of experience* Home of the largest crusher parts inventory on the East Coast. Fast turn-around and Rock Crushers available to reduce downtime. Mellott Total Service Care Available. Our team is focused: 200 dedicated crusher and screening specialists.

Learn MoreMaintenance Tips - Howard University Bison

2022. 6. 29. · Can crushers, however, occasionally require maintenance such as cleaning, inspection, repairs, and lubrication of moving components, much like other manual hand tools. These procedures assist in extending the life of a crusher and prevent or address any minor issues that may arise before they grow into more serious flaws that may cause the equipment

Learn MorePDF Crushing and Screening Handbook - AusIMMPDF

Crusher automation - ensures consistent and effi cient operation. Improves productivity and product quality while reducing maintenance costs by preventing overload situations. Stationary conveyors - a complete range of belt conveyors. Wide variety of widths, lengths, accessories and options. Various models incor-

Learn MorePortable Crusher Maintenance and Repair Process | DC Velocity

Portable Crusher Maintenance and Repair Process. The maintenance of the mobile crusher is of concern to many users, because only careful maintenance can effectively extend the service life of the equipment, thereby creating a more considerable economic value for the user. 1. Routine maintenance. (1) The equipment should be lubricated according

Learn MoreRock Crusher Maintenance - EzineArticles

Rock Crushers are no different. There are three types of maintenance that one must follow to properly maintain the crusher. They are - Preventive maintenance, Predictive maintenance and Reactive maintenance. Preventive Maintenance. This type of crusher maintenance plan need to be on a schedule and followed to keep up the crusher life.

Learn More

Leave A Reply