Ball mill liner - Zimaksan Co

Ball mill liner . One of the most common types of grinding machines used today in many industries is a ball mill. This device works by using mass media balls made of solid materials, embedded in a compartment or container, in such a way that the material is crushed and powdered at the time of the cavity of the compartment on the material.

Learn MoreBall Mill Liner Function - Wear Parts For Industry - Qiming Casting

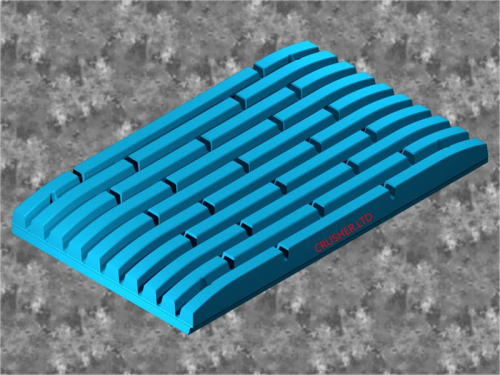

Ball mill liner plays a major role in protecting the inner wall of the anchor windlass. Different shapes of the ball mill lining plate can improve the grinding effect of the ball mill and improve the working efficiency of the ball mill. 1, flat ball mill liner, the surface smooth, suitable for installation in the fine grinding warehouse.

Learn MoreBall Mill Liners manufacturers & suppliers

Ball Mill Liners manufacturers & suppliers ; US$ 30-200 / Piece. (FOB Price). 50 Pieces (MOQ) · Yes · ISO 9001: ; US$ 10-200 / Piece. (FOB Price).

Learn MoreKey considerations when selecting a mill lining system

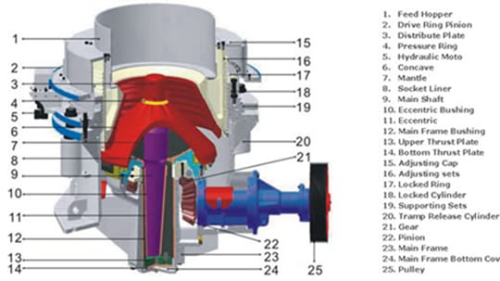

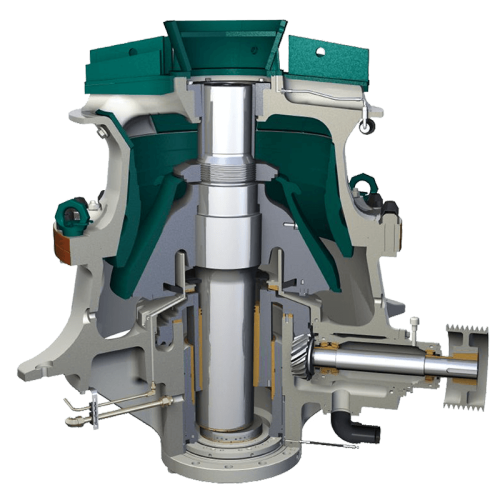

SAG and ball mills grind material through different actions and are usually applied in different stages of the process. SAG mills usually have a

Learn MoreSteel Ball Mill Liners

In Φ2.2 x 6m ball mill, the capacity is 3.2mt per hour on 2μm∼10μm, which has achieved leading level at home and abroad. In 2000, we designed the first set of the boltless liners applied in a

Learn MoreBall Mill Liners on sales - Quality Ball Mill Liners supplier

Boltless Ball Mill Liners Grinding Mill Power Plant / Ball Mill Parts Industry Grid Cement Mill Liners Wear Resistance With ZGCr5Mo Hardness AK5-15J High Abrasion Steel Mill Liners Standard AS 2027 CrMo 15 / 3 Ball Mill Liners (51) Large Martensitic Cr-Mo Alloy Steel 95 - 107 Hammer Crushers OEM Contact Now

Learn Moreball mill rubber liner

The rubber liner plate for ball mill cansatisfiedthe overflow type,grid-type and multi-chamber ball mill type. The maximum specification with wear-resisting rubber lining board of ball mill is Φ5500X8850. It has been used in the field of black metal mines,non-ferrous metal mines,chemical mines,golden mines and steel smelting,nonferrous metal

Learn MoreBall Mill Linings - Multotec

Ball Mill Linings from Multotec provide optimum wear lining solutions for the toughest applications, ensuring optimum grinding and crushing efficiency.

Learn MoreChina Ball Mill Liner,Mill Lining,Ball Mill Balls Manufacturer and

Ball Mill liners and compoments . Customized, fit-for-purpose mill parts and components that aim to improve the reliability of your machine. From a parts supplier to a full-service partner, TyCrusher part is here to support you, no matter the brand of your grinding ball mill. TyCrusher Parts is not only the leading manufacturer of pri me Crusher Wear Parts,but also as a expert for

Learn MoreMill Liner plate - mill linings Latest Price, Manufacturers

These liners are used in Ball mills where low contamination is required. Contamination with Alumina Ceramic lined ball mill is low due to their extremely low

Learn MoreBall Mill Liners Selection and Design | Ball Mill Rubber Liner

19/05/ · According to different grinding requirements, ball mill liners are roughly divided into 9 types, which are wedge-shaped, corrugated, flat-convex, flat, stepped, elongated, rudder

Learn MoreThe Ultimate Guide to Ball Mills

14/08/ · 5. The size of the ball mill is large, and it is necessary to carry out lifting work during the process of replacing the ball mill liner. The hoisting ball mill liner is the responsibility of the hoist. The lifting process requires attention to the operation of the wire rope and the hook. 6.

Learn MoreBall Mill / SAG Mill Steel Shell Liners - Unicast Inc

Ball Mill / SAG Mill Steel Shell Liners Unicast Shell Liners are cast in materials ranging from chrome-moly steels to high chrome white iron. A minimum

Learn MoreMegaliner™ mill liners - Outotec

Fast reline as a liner covers up to 8 m². A Megaliner™ element integrates multiple lifter and plate rows and has a minimum number of attachment points. In some cases, the lining consists of up to 80% fewer parts! It covers a large area of up to 8 m² and is light-weight in relation to size. Being several times larger than a traditional

Learn MoreMill Linings for Sale, Types of Ball Mill Liners. - ball mills supplier

The mill liner is installed inside the ball mill barrel to protect the inner wall of the barrel from the impact of materials and grinding media (steel balls, steel sylpebs, steel rods, etc.) to avoid

Learn MoreHome [ballmillrubberliner.com

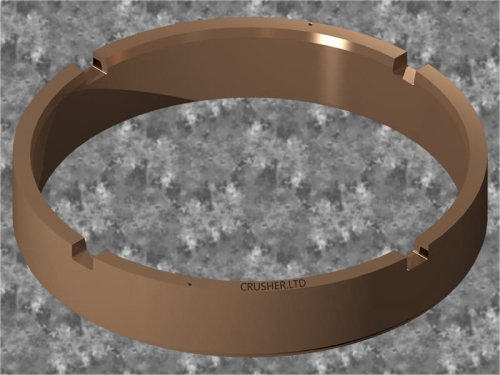

This product is an important part for conical ball mill and its call "feed end liners for ball mill' its main function is to protect the end cover of ball mill. The high wear-resistance head liner Read More . SIDE WALL CIRCLE. This product is also call blind disk for Ball Mill. It is a round plate which has all of the relevant bolt holes but

Learn MoreMill liners - Outotec

Mill liners optimized to meet your targets · Steel, Poly-Met™, Megaliner™, Rubber and Orebed™ mill liners for all mill types · Performance targets: · Continuous

Learn MoreMill Liners Manufacturer - MGS Casting

Ball mill liners from MGS Casting maximize the lifespan and performance of your ball mill, with a selection of rubber and rubber composite liners available. Refined through ongoing design improvements, our ball mill liners maximize uptime and service intervals while providing an improved crushing of the ore. Our ball mill liners solutions can

Learn MoreFC Mill Liners, Inc

Founded in 1970, FUCASA has been producing mill liners since the early 1980s and has become a principal suppler of cast iron and steel mill liners for AG, SAG, ball and rod mills in North America.

Learn More3 Reasons and 4 Improvement Measures for the Wear of Ball Mill Liner

24/06/ · The liner plays a decisive role in the quality of the ball mill.Its main role is to prevent the cylinder from wearing, it is also the easiest part to be worn. 3 reasons of the wear of the ball

Learn MoreBall Mill Liner ( Rubber , Polyurethane ) | Mill Rubber Linings Plate

Ball Mill Liner Plate Of Is Used To Protect The Cylinder From The Direct Impact And Friction Of The Grinding Body And Materials. At The Same Time, Different Liner Plates Can Be Used To Adjust The Movement State Of The Grinding Body, So As To Enhance The Grinding Effect Of The Grinding Body On The Materials, Improve The Grinding Efficiency Of

Learn MoreFactory Durable Ball Mill Lining For Sale High-quality Liner Plates For

Factory Durable Ball Mill Lining For Sale High-quality Liner Plates For Second Hand Ball Mill , Find Complete Details about Factory Durable Ball Mill Lining For Sale High-quality Liner Plates For Second Hand Ball Mill,Ball Mill Lining,Liner Plates,Second Hand Ball Mill from Mining Machinery Parts Supplier or Manufacturer-Guangdong Lieb Heavy Technology Co., Ltd.

Learn MoreSAG and Ball Mill Liner - EB Castworld

SAG and Ball Mill Liner system serves two purposes: Protect the mill shell from wear caused by the impact and abrasion of the mill charge, and to elevate and tumble the mill contents in the necessary manner to create a grinding action. To achieve this, the mill liner profile must be constructed from high wear resistant materials and incorporate correct geometry to help determine the elevation

Learn MoreEvaluation of Abrasive Wear Measurement Devices of Mill

mill liners of an ore dressing plant” for a mining industry mining company, M, and a mill liner behaviour and power draw we a ball mill.

Learn MoreBall Mill Liners

Ball Mill Liner components: Our ball mill liners solutions can be fitted with MultoMet composite lifter bars, shell plates and head plates. The MultoMet range utilises Hardox 500 wear-resistant

Learn MoreSelection and design of mill liners - ResearchGate

These mill configuration factors lead to an exceedingly high tendency for ore to pack between liners and the high ball load exacerbates liner

Learn More21 Factors You Must Know About Ball Mill Liner - Mining-pedia

05/05/ · 2) Binding ball mill liner is used in the first grinding chamber, which can make the grinding body rise higher with the greater impacting energy. 3) Convexo-plane shape ball mill liner is similar to the binding ball mill liner. 4) Wave shape ball mill liner is suitable for the rod ball mill. 5) Stepped shape ball mill liner is suitable for

Learn MoreBall Mill Liners - Vulcan Sanat

Ball mill liner. The ball mill are a special kind of grinding machine, in this machine the media balls along with the solids materials are placed in a

Learn MoreDouble Wave Ball Mill Liners - EB Castworld % Ball Mill Liners

Characteristics of Double Wave Ball Mill Liners. ⒈High wear resistance and impact resistance The alloy steel liner in dual-medium quenching is scientifically and reasonably formulated with alloy elements, so that the liner has good physical and chemical properties. The hardness is above HRC45-55, the impact toughness is above 25J, and the

Learn MoreEfficiency Improvement Of Ball Mill Liners By Simulation Of

A plant audit at the Sarcheshmeh copper complex indicted that due to the inappropriate design of ball mills liners, the liners wear and tear increased and

Learn MoreGrinding Mill Liners- An Overview

They are light weight and the balls infill the liners and provide an effective wear material. They are manufactured in manganese steel which

Learn More

Leave A Reply