Column distillation stages, calculating number - Big Chemical Encyclopedia

Distillation stage calculations are usually performed with ideal stages, The number of ideal stages required for the separation is divided by the overall column efficiency (Sec, 7,1,1) to obtain the required number of trays. In packed towers, the number of stages in the column is multiplied by the HETP ( Height Equivalent of a Theoretical Plate

Learn MoreColumn distillation optimum feed stage - Big Chemical

A distillation column will use the optimum feed stage. A liquid side stream is withdrawn on the third stage below the total condenser at a rate of 15.0 kmol/h. The feed is a two phase mixture

Learn MoreAnalysis of the connecting zone between consecutive sections

Tray by tray methods for the design of distillation columns cannot compete with column, it flashes adiabatically and spontaneously to the feed stage

Learn MoreFeb 21, - Chemstations

4. 26. · About 93 mol% of ethanol in feed and 5 mol% of n-propanol in feed is desired to be present in the distillate stream. Design a continuous distillation column to meet the desired specifications using Shortcut column in CHEMCAD and report the total number of stages, minimum number of stages, feed stage location, minimum and calculated

Learn MorePDF CHEMCAD DYNAMIC COLUMN CALCULATION User's Guide DistillationPDF

CC-DCOLUMN is an engineering software tool designed to simulate the behavior of distillation columns and their associated equipment. CC-DCOLUMN is designed to be used at all levels and stages of distillation process design and analysis. It can be extremely useful to: Quantify the requirements of operability, control loop tuning, changes in

Learn MoreOptimization and Dynamics of Distillation Column Using Aspen Plus

assumptions the distillation column consists of non-ideal column with following assumptions; x the liquid on the tray is perfectly mixed and incompressible. x tray vapor holdups are negligible. x dynamics of the condenser and the reboiler is neglected. x vapor and liquid are in thermal equilibrium (same temperatures) but not in phase equilibrium.

Learn MoreImpact of Feed on Liquid and Vapor Flows in a Distillation Column

Organized by textbook: https://learncheme.com/Uses an interactive simulation to describe the impact of the state of the feed to a distillation column on the

Learn MoreImproving the distillation energy network - DigitalRefining

The following are common strategies that can be applied to practical energy improvement projects. Feed temperature. Feed temperature is a major factor influencing the overall heat balance of a distillation column system. Increments in the feed enthalpy can help reduce the required energy input from the reboiler at the same degree of separation.

Learn MoreWhat are the effects of feed tray location in distillation column?

Feed tray determines the nature of the column. If feed tray is on the top then it is called a stripper column , if the feed tray on the bottom of the column

Learn MoreDistillation - Chemical Engineering Separations: A Handbook for Students

generic stage number, stage 1 is at the top of the column = metric that reflects the physical state of the feed stream (unitless) = reflux ratio = bubble-point temperature of the feed stream at the column operating pressure (temperature) = dew-point temperature of the feed stream at the column operating pressure (temperature)

Learn MoreFeed-Stage Multiplicity in Multicomponent Distillation

A binary mixture of light and heavy components is fed as a saturated liquid into a distillation column with 20 ideal trays plus a partial

Learn MoreDesign of Distillation Column||Optimum Feed stage|| Design

Jan 11, · Instagram:https://www.instagram.com/cheme.friends/Email: [email protected]

Learn MoreOptimization of Feed Locations for Double-feed Columns

It is found that the appropriate feed stages of a double-feed column are positions For chemical plants, typical double-feed distillation columns are

Learn More5 - Multi-Stage Distillation - Alan Lane

5.4 200 mol/s of an n-hexane (30 mol%) and n-octane (70 mol%) mixture is fed to the middle stage of a three-stage distillation column operating at 1000 mm Hg. The feed is a mixture of vapor and liquid such that half contributes to the vapor flowing up from Stage 2 to Stage 1 and half contributes to the liquid flowing down from Stage 2 to Stage 3.

Learn MoreLecture 11. Binary Distillation (1) [Ch 7] [Ch. 7

Optimal and nonoptimal locations of feed stage Distillation (fractionation) vs. absorption and stripping method for trayed towers

Learn MoreAnalysis of the effect of feed composition and thermal

A trayed distillation column is normally divided into a series of stages to allow multiple liquid-vapor contacting leading to a cascade of equilibrium stages.

Learn MoreColumn distillation stages, calculating number - Big Chemical

Distillation stage calculations are usually performed with ideal stages, The number of ideal stages required for the separation is divided by the overall column efficiency (Sec, 7,1,1) to

Learn MoreTwo Phase Flow Feed Pipes to Distillation Columns

Performance* of distillation towers can be adversely affected by the piping sizing and layout upstream of a column, something.

Learn MorePDF DISTILLATION COLUMN DESIGN AND ANALYSIS - AIChEPDF

COLUMN DESIGN: EIGHT PRACTICAL STEPS 1. Define product specification(s) 2. Choose an operating pressure 3. Choose appropriate VLE data 4. Calculate the number of theoretical trays 5. Select a tray efficiency 6. Select appropriate tower internals 7. Perform tower sizing and tray hydraulics 8. Select a process control scheme 14

Learn MoreOptimum Feed Tray Location in an NGL Fractionation Column

A fractionator is a column equipped with trays or packing materials for separating a mixture of components into two or more products,

Learn MoreDistillation Design The McCabe-Thiele Method - CHERIC

to design a distillation column to produce these results. • With the McCabe-Thiele Method, the total number of necessary plates, as well as the feed plate location can bidd if i lbbe estimated,

Learn MoreDistillation Tutorial II - URI Engineering Computer Center

The collection of trays above the feed stage is called the rectifying section of the distillation column and distillate product is generally withdrawn from

Learn MoreFeed Stages in a Distillation Column - Wolfram Demonstrations Project

The flow rates to and from a feed stage of a distillation column are proportional to the thickness of the arrows in the figure. Liquid (blue) flows down the column and vapor (green) flows up. Use the slider to change the quality of the feed stream.

Learn MoreDistillation Column - an overview | ScienceDirect Topics

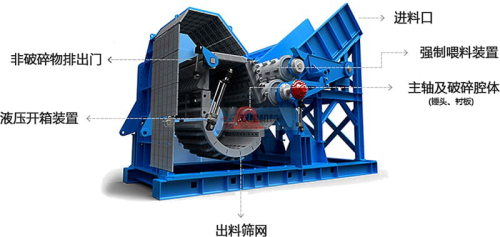

A typical distillation column consists of several major parts: 1. A vertical shell where separation of the components is carried out. 2. Column internals such as trays, or plates, or packings that are used to enhance component separation. 3. A reboiler to provide the necessary vaporization for the distillation process. 4.

Learn MoreColumn - processdesign - Process Design Open Textbook

Reflux ratio; Feed point location; Column Pressure; Number of equilibrium stages/real stages. Assuming that we have already

Learn MoreDistillation Columns - an overview | ScienceDirect Topics

The layout of a simple distillation column is shown in Figure 1. A single feed enters the column at the side and two products are produced: the light or most volatile components are withdrawn from the top and heavy components are removed from the bottom.

Learn MoreDISTILLATION COLUMN DESIGN AND ANALYSIS - AIChE

A distillation column is a series of equilibrium flashes with two feeds and two product streams Exiting liquid is at bubble point Exiting vapor is at dew point Compositions obey the equation yi

Learn MoreFeed distribution in distillation: Assessing benefits and limits

As mentioned, simple column design using the CPM method is much the same as boundary value method, but the CPM method's true

Learn MoreStage-to-stage calculations of distillation columns by fixed-point

Jun 08, · For simplicity, a distillation column with one single feed on stage N F (N F = 2 in the example of Fig. 2) and without any side-draws is considered. The method described in the

Learn MoreColumn distillation optimum feed stage - Big Chemical Encyclopedia

A distillation column will use the optimum feed stage. A liquid side stream is withdrawn on the third stage below the total condenser at a rate of 15.0 kmol/h. The feed is a two phase mixture

Learn MoreSingle Stage Flash Distillation Methods - ChemEnggHelp

Heat Balance for Flash Distillation The quantity of vapor fraction depends upon the heat supplied to the feed and pressure drop across the valve. So, we can write an enthalpy balance for the flash distillation system as below, F*HF = V*HV + S*HS Where, H F, H V & H S are the enthalpies/mole of feed, vapour and liquid streams respectively.

Learn More

Leave A Reply