PDF "Computer Aided Design of Jaw crusher"PDF

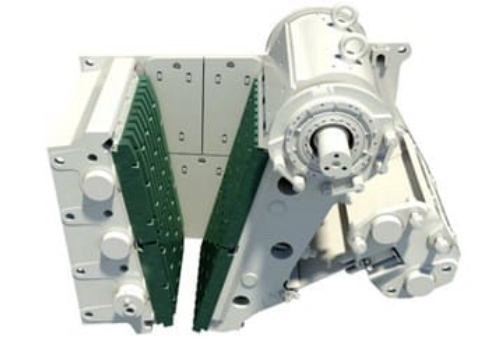

The characteristics of such crusher are: 1. Larger, rough, massive and sticky rocks can be crushed. 2. They are easy to maintain 3. It is very simple to adjust and prevent much of wear and are easy to repair, 4. Moving jaw can be reinforced with high tensile manganese to crush very hard rock. Figure 1.2 2) Dodge Type Jaw Crusher

Learn Morecrusher design calculation - Crushing and Screening Plant

crusher design calculation pdf- [crusher and mill] Crushing Plant Design and Layout Considerations. Operating schedule calculation - for 3 x 8 hours per shift rocks per year 365 (1) Wright Engineers Ltd. Internal Design and Fabrication of - IJIRSET Design and Fabrication of

Learn MoreDesign Calculations For Crusher Machine

Chapter 2: Design and Calculation 2.1 Design of V-Belt drive 7 2.2 Design of Shaft 10 2.3 Design of Hammers 14 2.3.1 Using Impact Bending 14 A crusher is a machine designed to reduce large solid chunks of raw material into smaller chunks.

Learn MoreComputer Aided Design of Jaw crusher” - ethesis

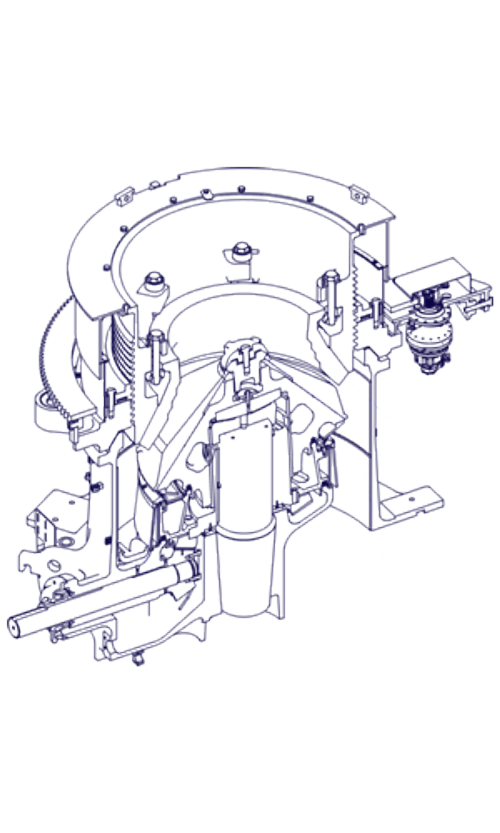

4.2 Role of flywheel in a jaw crusher. 32. 4.3 Stresses in a flywheel. 34. 4.4 Design calculations. 38. 4.5 Design of spring for tension bar.

Learn MoreDesign Calculations Of Jaw Crusher-HN Mining Machinery Manufacturer

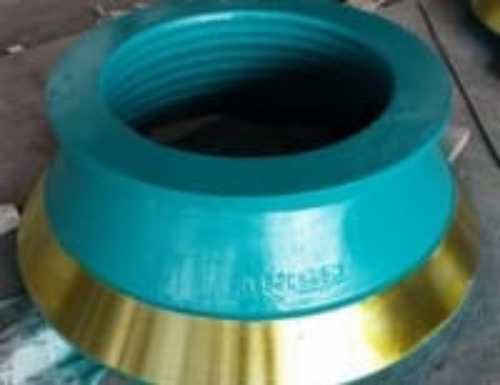

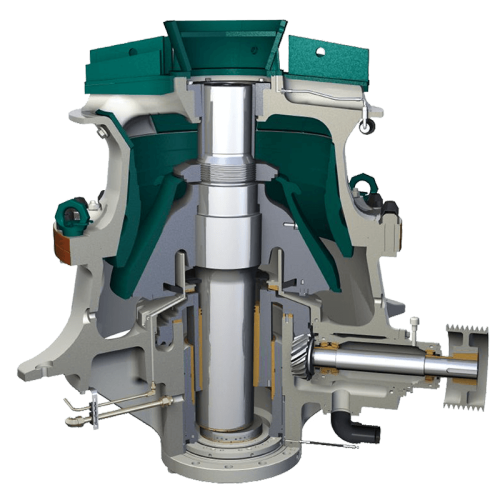

Design Calculation Of The Jaw Crusher In Nigeria. Calculation In The Design Of A Grinder Or Crusher. Design calculation of a gyratory crusher pdf cs cone crusher rebuild specs amroninternationalin a crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dustthe earliest crushers were hand held stones where the

Learn Moredesign calculation of jaw crusher

Design And Calculation Of Flywheel Of Jaw Crusher. Design And Calculation Of Flywheel Of Jaw Crusher Hydraulic jaw crusher fly wheel design - rajcatererscoinaw crusher working principle 911 metallurgist jul 2 a sectional view of the single-toggle type of jaw crusher is shown belowturn flywheel so that counter weights are parallel with movable jaw the setting adjustment system is designed

Learn MorePDF "Computer Aided Design of Jaw crusher" - National Institute of ...PDF

Chapter 4 Design of flywheel for Jaw crusher 4.1 Flywheel 32 4.2 Role of flywheel in a jaw crusher 32 4.3 Stresses in a flywheel 34 4.4 Design calculations 38 4.5 Design of spring for tension bar 40 4.6 Final results and Discussion 41

Learn MoreDESIGN AND ANALYSIS OF IMPACT CRUSHERS

1.4 Advantages of Impact crushers 5 1.5 Principle of Operation 5 Chapter 2: Design and Calculation 2.1 Design of V-Belt drive 7 2.2 Design of Shaft 10 2.3 Design of Hammers 14 2.3.1

Learn MoreMmer Mill Crusher Design Calculations - VCharty Crusher

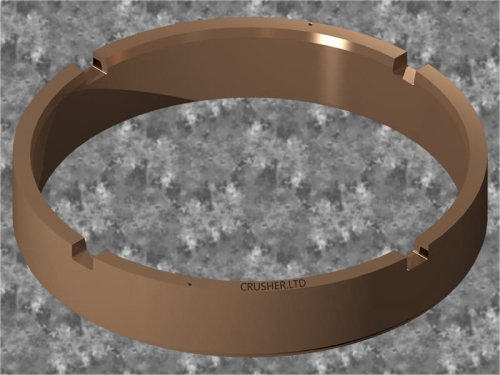

2. design analysis and calculations 2.1 roll crusher geometry it is necessary to estimate the maximum size of the mineral particles that can be fed into the machine for a known roll diameter, roll length and roll gap. it is convenient to assume that the particle is spherical and the roll surfaces are smooth when calculating for.

Learn MorePDF Crushing Plant Design and Layout ConsiderationsPDF

Table 2 Production Requirements - Typical Example: 60" x 89" primary crusher & mill feed conveyor system Operating schedule calculation - for 3 x 8 hours per shift Days per year 365 Tonnes per year 32,850,000 Metric tonnes per day 90,000 TOTAL TIME AVAILABLE 8,760 Hours per year UNPLANNED DOWNTIME

Learn MoreDevelopment Design for Jaw Crusher Used in Cement Factories

Keywords—Jaw Crushers, Cement Factpries, Manufacturing and Design. count for these the equation has to be modified using factors that.

Learn MorePDF Design and Analysis of A Horizontal Shaft Impact CrusherPDF

Fig.3 Scheme of breaking process in crusher [1] Mass Balance (Size distribution) According To size distribution model given by whiten (1972)the particles are represented in a discrete form of vectors [1] (f) and (p) where f = feed vector P = product vector C = Classification operator, computes the probability of breakage of each particle size.

Learn MorePDF DESIGN AND ANALYSIS OF IMPACT CRUSHERS - National Institute of ...PDF

Stamp mills- Use cans to lift weighted vertical hammer which are dropped by gravity to crush the material. DESIGN PARAMETERS: The principal design parameters that drive crushing plant selection and configuration included. 1. Production Requirements 2. Ore characteristics 3. Project location 4. Operational considerations 5. Climate conditions 6.

Learn MoreAMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Jaw Crusher Fundamentals Vertical Height = 2 x Gape Width of Jaw > 1.3 x Gape < 3.0 x Gape Throw = 0.0502 (Gape) 0.85 Gape is measured in meters. Jaw crusher action Jaw Crusher Sizes and Power Ratings Size is specified in terms of the gape and width, typically listed as

Learn MoreCrusher Standard Calculation Association

cone crusher design calculation pdf · crusher standard calculation association coal pdf · coal crusher standard calculation association coal pdf · Calculation Coal

Learn MoreAggregate Processing Plant Design Calculation - Crusher Mills

design of crushing plant steve mellor pdf - Rocks Process -KWS. aggregate processing plant design calculation Steve Mellor explains why uses aggregate risk as a tool for managing the risk Before starting a QRA on a

Learn MoreMODELLING, SIMULATION AND OPTIMISATION OF ... - CORE

design of a control model utilising two crusher variables and a self-tuning control algorithm. Kick and Bond are perceptions of one universal equation.

Learn MoreDesign Calculations Of Jaw Crusher-HN Mining Machinery

Design Calculation Of The Jaw Crusher In Nigeria. Calculation In The Design Of A Grinder Or Crusher. Design calculation of a gyratory crusher pdf cs cone crusher rebuild specs amroninternationalin a crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dustthe earliest crushers were hand held stones where the

Learn MoreCrushing Plant Design and Layout Considerations

Example: 60” x 89” primary crusher & mill feed conveyor system Operating schedule calculation - for 3 x 8 hours per shift Days per year 365 Tonnes per year 32,850,000 Metric tonnes per day

Learn MoreRoll Crusher Design Calculations

Crusher Power Calculation. crusher power calculation. home - power calculation of double roll crusheraxwell crushtech, jaw crushers, loaders, feeders the maxwell smooth double roller crusher has very easy and accurate css setting through square threaded jack without insertion of sims or any additional part usagehe roll change is easy as it is

Learn MoreManufacturer Jaw Crusher Design Calculation Pdf - Alibaba

jaw crusher design calculation pdf ; C6X110, 850×1100, 720, 80-200, 160-550 ; C6X125, 950×1250, 800, 125-250, 280-760

Learn MoreDESIGN AND FABRICATION OF CAN CRUSHING MACHINE

The Can crushing machine which is fabricated This is used to crush Aluminium 3.1 Design Calculation for pulley and V-belt.

Learn MoreDesign and Fabrication of Glass Crushing Machine - EasyChair

The crusher is a device which is used for reduction in size ratio of particle from large particles into the small size particle. Here, the glass crusher used is of type horizontal 3.1 Design Calculation The estimation of shaft diameter, torque required ,power, area used for crushing are selected with calculation as shown below,

Learn Moredouble roll crusher calculation

double roll crusher calculation · Roll Crushers · DESIGN OF MECHANICAL CRUSHING MACHINE · DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER · Roll Crushers.

Learn MoreDesign and Analysis of Rotor Shaft Assembly of Hammer Mill

Design and Analysis of Rotor Shaft Assembly of Hammer Mill Crusher The equation may be written as compressive) is given by the bending equation.

Learn MoreEstimate Jaw Crusher Capacity - Mineral Processing & Metallurgy

jaw crusher production capacity Example capacity calculation of a 10″ x 20″ (250 mm x 500 mm): Pp = 2800 (2.8 SG) e = 0.2 (halfway between dolomite and sandstone) A = 250/1000 x 500/1000 Wj = 0.5 Nj = 225 = 2800 x 0.25 x 0.5 x 0.5 x 225 x (1-0.2)/60 = 525 kg/hr = 13 TPD vs 300 to 420 TPD —> I can't make this work!

Learn MoreDESIGN OF A BEVERAGE : A LEAN ... - iaeme

poisson's ratio were used in the design calculation and simulation of the crusher. Each of the component part and the complete assembly of the machine was

Learn MoreBall Mill Design Calculation | Crusher Mills, Cone Crusher, Jaw Crushers

ball mill critical speed calculation - CGM Grinding Plant. Apr 01, · Ball mil design calculation? . Ball mills are normally operated at around 75% of critical speed, so a mill with diameter 5 metres will .

Learn MoreDesign Calculation For Waste Materials Crusher

Calculation Cone Crusher Design. North Carolina Division of Air Quality PSD Preliminary Oct 22 2007 trucks will transfer the large pieces of rock to the primary jaw These smaller stones are then conveyed to the secondary crusher that is located clay quarry spoils bauxite (principal ore of aluminum) fly ash bottom ash sand and mill material

Learn MoreEstimating Crushing Force of Cone Crusher using ... - IRJET

Mineral processing industries as Secondary or Tertiary stage crusher to crush blasted rock material. In this work to calculate the output from a cone crusher,

Learn Moreen/jaw crusher design calculations.md at main - GitHub

jaw crusher design calculation jaw crusher design calculation crushers are mainly of three egories ie cone crusher,jaw crusher and calculation per unit mass

Learn More

Leave A Reply