US5765769A - Method for adjustment of jaw crusher toggle block, and device used therein - Google Patents

The swinging jaw 11 is suspended from the swinging jaw shaft 13 as the fulcrum, and swings with the movement of the pitman 21 moving up and down with the rotation of the eccentric shaft 2, and the toggle mechanism on either side of pitman. In this case, a double

Learn MoreHow does a Single Toggle Jaw Crusher work? | RUBBLE MASTER

Jaw crushers are used for a variety of natural stone materials: soft and hard stones, highly abrasive rock, ore, and for concrete recycling with lots of rebar. Easy maintenance & low wear Jaw ties and cheek plates last for a very long time and can be changed easily and quickly. A single toggle jaw crusher works like a giant nut cracker

Learn MoreHow to Change the Toggle Plate Jaw Crusher - The Uplift

The first method is by changing the gaskets which are located between the supporting base of the toggle plate and the frame of the body, and the other method is simply by adjusting the two wedge blocks which are located between the toggle plate and the frame of the body. The last function of the jaw crusher is nothing but the functioning as a

Learn MoreJaw Crusher - Toggle Plate Seating AREA

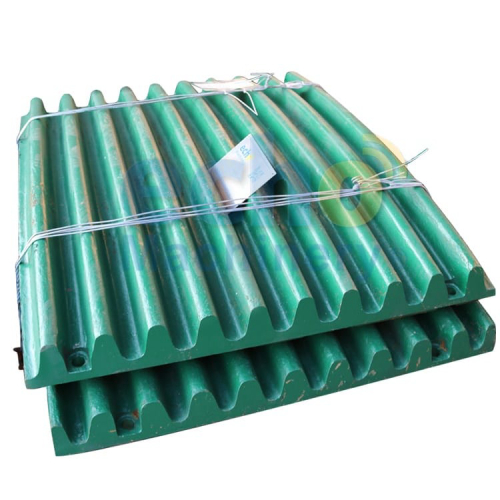

Jaw crusher plate - over 6,550,232 jaw plate, check plate, toggle plate are the spare parts of jaw crusher main material is high manganese steel.We can manufacture different plate Jaw Crusher,Jaw Crushers for sale,Used Jaw Crushing Machine The PE series Jaw Crusher,

Learn MoreDouble Toggle Jaw Crusher VS Single Toggle Jaw Crusher - Dry Mortar Plant | Sand Dryer | Cement Silo Manufacturer | FUREIN

10/19 · The up and down movement of single toggle jaw crusher can promote the discharge of material, and it is easy to break large materials, and its crushing efficiency is higher than that of double toggle jaw crusher. The disadvantage is that the jaw plate wears out quickly.

Learn MoreJaw Muscle Soreness treatment near Hillsboro, OR

Find top doctors who treat Jaw Muscle Soreness near you in Hillsboro, OR. Book an appointment today! LIST YOUR PRACTICE ; Dentist ; Pharmacy ; Search . Find a doctor near you. Search doctors, conditions, or procedures . The location you tried did not return a result. Please enter a valid 5-digit Zip Code.

Learn MoreSingle Toggle Jaw Crusher Specification

Single toggle jaw crushers for mining, quarrying and . Machine specifications. JW40: JW42: JW55: Feed Opening: mm: 1000 x 625: 1070 x 760: 1400 x 760: inch: . The JW Group of

Learn MoreSingle Toggle Swing Jaw Crusher - MAX Plant

MAX Plant Single Toggle Jaw Crushers are built for operation in tough and continuous aggregate and mineral processing applications.

Learn MoreSingle Toggle / Double Toggle - Jaw Crusher

Four Toggle Bearing required in a jaw Crusher. TOGGLE PLATES : The toggle plates are fabricated from M.S plates and well designed for correct jaw movement. The toggle bearing serves as safeguard in case of uncrushed materials enters between the jaw plates. The Toggle plates get broken saving the breakage of other parts like bearing, Crank shaft

Learn MoreJaw Crusher Working Principle - 911 Metallurgist

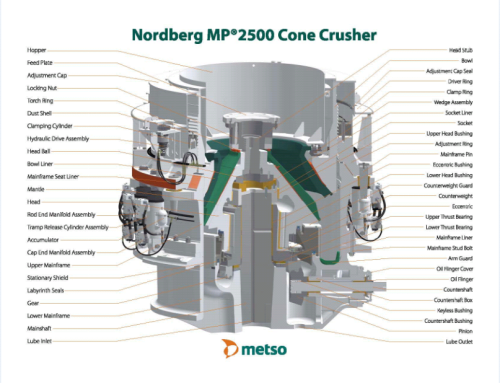

The Double-toggle has its moveable jaw driven via an eccentric shaft that moves the rear and front toggles down and up on

Learn MoreWhat is a Jaw Crusher? – MEKA Crushing Equipment

Toggle plate compressed between moveable jaw and main body. This mechanism ensures that any point on the moving jaw moves in an elliptical orbit. This mechanism makes a movement aka four bar linkage movement. Through this movement, the movable jaw applies both pressure and friction forces to the material to be crushed.

Learn MoreUsed Jaw Crushers for sale. equipment & more | Machinio

42 x 48 in (1 x 1.2 m) Allis Chalmers jaw crusher. USED. Manufacturer: Allis-Chalmers. - Double toggle jaw - Removed and dismantled - In storage - Bare jaw, no motor - A1 type machine - Feed opening: 42 x 48 inches - Throughput: 290-475 TPH - Closed side setting: 15-25 cm - 150-175 HP motor required. USA.

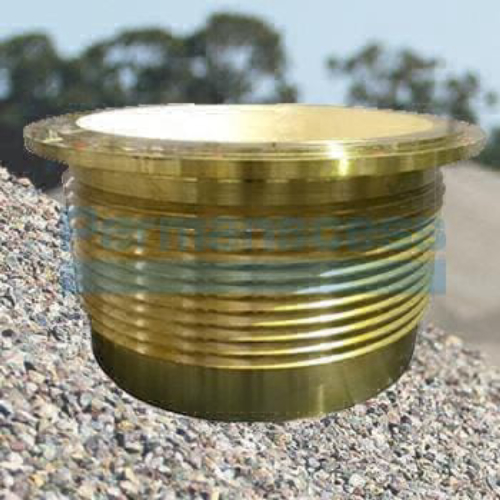

Learn Moresingle toggle and double toggle jaw crusher | MP1000 SOCKET LINER FOR

Manufacturer of Jaw Crushers - Single Toggle Jaw Crushers, Double Toggle Jaw Crushers, 36x24 JAW CRUSHER and 30x24 JAW CRUSHER offered by jaw rock crusher plates MP1000 SOLENOID VALVE 2 POS. 2 WAY CARTRIDGE T hp4 belt guard, assy painted version for hor lime stone inpact crusher main shaft bushing manufacturers from rxtq60tavjua

Learn MoreJaw Crusher - ScienceDirect

Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw). The faces of the plates are made of hardened steel. Both plates could be flat or the fixed plate flat and the moving plate convex. The surfaces of both plates could be plain or corrugated.

Learn MoreJaw Crusher - Eastman Rock Crusher

Capacity. 1-1120t/h. Output Size. 10-350mm. Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications. mining, quarry, construction waste recycling, aggregate making, etc. Materials.

Learn MoreSource The Ideal Wholesale toggle plate jaw crusher - Alibaba

Hot sale jaw crusher toggle liner plate replacement parts for jaw crusher JM 1208 protection wear plate. $2.00-$3.00 / kilogram. 1000.0 kilograms (Min Order) 12YRS. CN. Supplier > Contact Supplier. 1/6. spare parts toggle plate and seat for crusher c105 C106 c110 jaw crusher. $125.00 / piece. 1 piece (Min Order) 10YRS. CN. Supplier > 5.0

Learn MoreSingle Toggle Jaw Crusher - Mechtech Engineers

With a robust build, and designed for versatile applications, MechTech Single Toggle Jaw crushers are capable of crushing soft to medium and very hard

Learn MoreSingle Toggle Jaw Crusher at Best Price in India

SRIRAM JAW CRUSHERS are designed for primary crushing of various Hard and Abrasive minerals with minimum rub action. There is no action of rub but by

Learn MorePDF Engineered for the toughest feed materials ® C Series™ jaw crushersPDF

and ASC also includes a toggle plate for optimum jaw crusher protection. Safe and effortless operation and maintenance The setting of the C Series jaw crusher can be adjusted with two wedges without shim plates. The adjustment system is mechanically moved as standard, and the fully automatic hydraulic option is available

Learn MoreJaw Crusher Toggle Plates vs. Hydraulic Toggle Relief

A toggle plate basically operates like a fuse. If any material enters a jaw crusher that cannot be crushed, whether due to its size or

Learn Morefunction of toggle joint in jaw crusher

The fine jaw crusher range includes: Essa® JC1250 Fine Jaw Crusher - the scaled down and more affordable version of our fine jaw crushers. Evolved from an intensive two-and-a-half-year research and development program to present power and value for high workload crushing. Clever design makes it easy for you to control product sizing.

Learn Morejaw crusher double toggle

WhatsApp: https://wa.me/8613621919955?text=Pls+send+us+this+message+first%2C+then+we+will+arrange+for+the+right+sales+engineer+to+serve+you%21+Your+Unique+Co

Learn MoreSingle Toggle vs Double Toggle Jaw Crusher

The double toggle jaw crusher has two forms of working direction: one is a swing motion toward the fixed die plate, and the other is a vertical

Learn MoreJaw Crusher Manufacturer | Propel Industries

JAW CRUSHERS AVJ SERIES Propel AVJ series single toggle Jaw Crusher offers maximum possible fatigue strength and best reliability with various mounting possibilities. Details may

Learn MoreJAW CRUSHER SERIES - Mining and Rock

Our jaw crushers are of the single-toggle type and feature a deep, symmetrical crushing chamber, a large feed opening for its size, and an ideal nip angle that offers smooth material flow and high reduction efficiency. Jaw crushers are normally capable of aratio of

Learn MoreJaw Crusher Working Principle – StudiousGuy

Working Principle of a Jaw Crusher. A jaw crusher mainly works on the principle of reciprocating motion exhibited by the moveable jaw of the jaw crusher. The repeated movement of the jaws results in the development of compression force that further causes the breakdown of the rock or the ore placed between the two jaws into smaller pieces.

Learn MoreJaw Crusher Double Toggle

Single and double toggle jaw crushers on first appearance seem to overlap their application as a primary crusher; however, they both have their specific advantages. 1 - KUE KEN 16" x 36" Double Toggle Jaw Crusher with 100 HP motor Featured Products.

Learn MoreCJ411 Single-Toggle Jaw Crusher For High Production

CJ412 single-toggle jaw crusher is engineered for the toughest applications thanks to its heavy-duty design. Characterized by an attention to detail in its design and manufacture, this machine is an excellent choice when you need high production and low total cost.

Learn MoreSingle Toggle Jaw Crusher With Unique Benefits

The single-toggle jaw crusher is mainly composed of a frame, a jaw plate, two side guard plates, a toggle plate, a flywheel, a shaft, and a regulating device.

Learn MoreSingle Toggle Jaw Crusher

Each machine is backed by the Jaques total after-market service and spare parts support. We have been manufacturing jaw crushers for 120 years and over

Learn MoreToggle Plate | Genuine Alternative Jaw Crusher Parts

Toggle Plate is a simple & low-cost but very important part of jaw crusher. It is usually made of cast iron, and it is used to hold the lower part of the jaw in position, it also serves as a safety

Learn More

Leave A Reply