improving liner wear profile - Crushing, Screening & Conveying

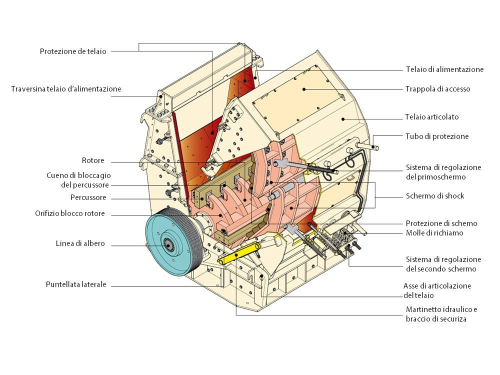

The attachment (cone crusher wear profile.pdf) shows a before/after profile of wear parts from a cone crusher. The light line is the original profile. The bold line is the worn profile. The phantom shows the worn liner profile where it would have been positioned in the crusher just prior to removal.

Learn MoreCrusher Wear Parts

Crusher Spares (Australia) stock and supply an extensive range of aftermarket manganese cone crusher liners to suit the majority of the different makes and

Learn MoreCrusher Wear Parts & Liners | Wear & Impact Resistant Steel

Find crusher wear parts and liners for all types of impact crushers. Clifton Steel can make the right wear liner for the job.

Learn MoreKenco Longer Wearlife Parts | HSI Apron Liners

Tungsten carbide impregnated AR steel apron liners out wear manganese in certain HSI crusher applications; Elimination of premature apron liner wear greatly

Learn MoreProlonging Cone Crusher Liners Working Life - Precision Casting

This occurs when the stone being crushed is forced against the liner causing it to 'work-harden'. 'Green' manganese starts off at around 25 Rockwell (250 Brinell) and can achieve a hardness of approximately 60 Rockwell (660 Brinell) after a period of work-hardening. Liner selection When selecting a crusher the bowl liner also varies in type:

Learn MoreMantle | Bowl Liner - Crusher Wear Parts

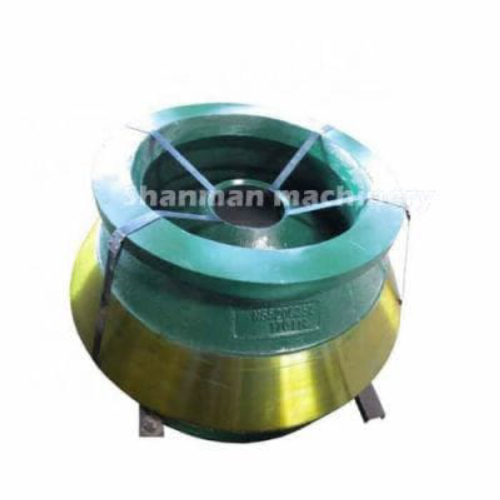

Why Choose HONGFEI Mantle & Bowl Liner ① We offer OEM interchangeable cone crusher parts & liners; ② We offer a variety optional materials of cone crusher

Learn MoreCrusher Wear Parts | Weir ESCO

ESCO is a leading developer of heavy-duty wear parts for all major makes and models of cone, jaw and gyratory crushers. ESCO crushing experts work with customers to recommend a

Learn MoreStudy on Liner wear in Single Toggle Jaw Crushers - IJSER

Index Terms—Sliding; jaw liner; single toggle jaw crusher; abrasive wear the causes of the rapid abrasive wear surrounding jaw liners.

Learn MoreLiner wear in jaw crushers | Request PDF - ResearchGate

Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major

Learn MoreCrusher Liner Supplier Manganese Steel Mantle Bowl liner Casting Mining

Crusher Liner Supplier Manganese Steel Mantle Bowl liner Casting Mining Cone Crusher Wear Parts >=1000 Kilograms. $1.88. Model Number: CH420/430/440/660/870 Shipping: Support Sea freight Lead Time: Quantity(Kilograms) 1 - 1000 >1000: Est. Time(days) 20: Negotiable: Product Details. Company Profile. Report Suspicious Activity

Learn MoreCrusher Liners - H-E Parts

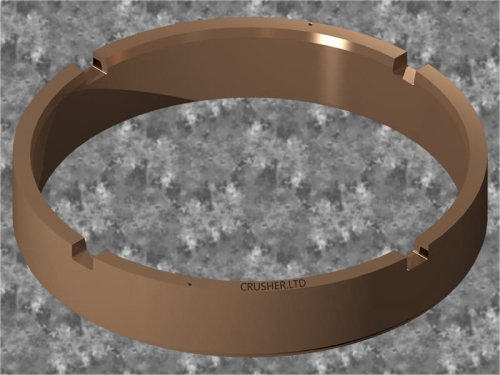

At H-E Parts we don’t just pride ourselves on providing industry benchmark wear liners, but also the safest lifting assemblies available for quick, reliable and zero harm servicing. Our proprietary CME™ crusher liners , designed for use with our ™ and ™ mantle lifting systems, offer our customers the safest means available to remove and replace wear liners.

Learn MoreLinex Bed Liner in Hillsboro, OR with Reviews - YP.com

Find 4 listings related to Linex Bed Liner in Hillsboro on YP.com. See reviews, photos, directions, phone numbers and more for Linex Bed Liner locations in Hillsboro, OR.

Learn MoreResearch on the Wear Behavior of the Fixed Cone Liner of a

4−7) The frequent replacement of the fixed cone liner not only affects the working efficiency of the cone crusher, but also costs a lot of

Learn MoreAnalysis of the Wear Failure of Cone Crusher Liner at Copper Mine

The key step of wear failure analysis is to analyze the morphology of the wear surface, so the sample must be taken from the fresh wear surface of the wear debris. The moving cone (liner) we sampled was just removed from the cone crusher and shipped back in time. The broken cone crusher liner is cut into large samples by oxygen-acetylene flame

Learn MoreLiner wear in jaw crushers

Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these

Learn MoreGyratory Crusher Parts - Wear Parts For Industry | Qiming Casting

Our users report that teeth greatly reduce slippage, and improve both production and liner wear life. On the other hand, we had designed TIC inserts gyratory mantle for our customers. Based on this design, our TIC insert mantle span life can be 2-3 times than normal manganese gyratory mantle. Gyratory Concave Designs

Learn MoreCrusher Liners | Cone Crusher Liners | Crushing Wear Parts

Crusher Liners CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years' experience supplying crushing wear parts to global mining and mineral processing, oil sands, steel, cement, power and aggregate customers.

Learn MoreCrusher Wear Parts Selection Guide Rev 002

Mantle & Bowl Liners. Blow Bars Selection. Blow Bars. Curtain Liners. CONTENTS. 02. -05. 06. -08. 09. -10. 11. -12. 02. CRUSHER WEAR PARTS SELECTION GUIDE

Learn MoreHow Long Should Rock Crushing Equipment Liners Last? - Mellott Company

Typically, in a HP-style crusher, the optimal utilization target is 50 to 55% of the liner. For a Symons-style crusher, targeted utilization should be 60 to 65% to maximize liner use before replacement is required. To calculate liner utilization, weigh the liners before they're installed. Upon removal, weigh them again.

Learn MoreCone Crusher Liners | Crushing Wear Parts

We are a leading manufacturer and supplier of quality crusher liners and wear parts, customized for each application. Get in touch with us today to learn

Learn MoreCone Crusher Liners: How to Select and When to Change

If the liner is wearing evenly throughout the chamber, you should consider changing it when it has worn down to about 1” (2.5 cm) thick at the

Learn MoreWorld-Leading Crusher Liners - CMS Cepcor

CMS Cepcor® stock a wide range of cavity liner options for cone crushers along with many jaw plate tooth profile options for jaw crushers and various

Learn MoreCrusher Wear Liners - manufacturer, factory, supplier from China

Top-performance Gyratory crusher liners For Mining Crusher. Brand: TyCrusher Parts Packaging: 1.Wooden case special for expo Supply Ability: 60000 Tons/Year Min. Order: 1 Piece/Pieces The gyratory block is one of the main parts of the gyratory crusher and the gyratory plate hammer is equally important can protect the machine to re

Learn MoreJaw Crusher Parts Wear Liner Side Plate Suit for C95 Mining

details about China Jaw Crusher Spare Parts, Jaw Crusher Side Plate from Jaw Crusher Parts Wear Liner Side Plate Suit for C95 Mining Machine - Jiangsu Hyton Mechanical Equipment Co., Ltd. Sign In Join Free For Buyer Search Products & Suppliers

Learn MoreJaw Crusher Liners | Foreman Equipment

OEM Crusher wear parts designed to match original design specifications ensuring the best performance from jaw, cone, and impact crushers Office - Toll Free: 888-852-9021 | 44109

Learn MoreManganese Mantle Bowl Liner Suit Cone Crusher Wear Parts T900

Hyton produce High manganese casting liners mainly include Mantle, Bowl Liner, Feed Cone , jaw plate, check plate, Arm Liner , Steel Ball ,and etc. Cone Crusher Spare Parts-Cone Concave Advantage and Features. 1. Use: Wear parts for crushers in the quarry, mining, cement, aggregate, recycling, shredding and demolition fields etc. 2.

Learn MoreHYDROSET CYL BUSH S&H3000 | crusher wear liners

HYDROSET CYL BUSH S&H3000 | crusher wear liners. c160 spider rotex 125, spider 95 shore a red jaw exercises rotex coupling catalogue. CH870i and CH895i, it has a varying feed opening that is ideal if the crusher feed is not calibrated. crusher wear and spare parts HP200 CAPILLARY 0.560 HT CAP2 4.25 ft cone crusher concrete crushing

Learn MoreCrusher Wear Parts - Foreman Equipment Ltd

Wear occurs in all crushers, but you can help control costs by choosing the right liner configuration for the desired application. Crusher wear parts from

Learn MoreAR Steel Crusher Liners - Ford Steel

Our company provides crusher wear liner supplies to a wide range of industries including: Sand & Gravel; Cement; Construction.

Learn MoreCrusher Wear Parts For Jaw, Cone, Impact, VSI, and Gyratory Crusher

Crusher Wear Parts By Qiming Machinery®. Qiming Machinery is a leader crusher wear parts foundry in China, which manufactures jaw, cone, impact, VSI, and gyratory crusher wear parts for all popular brands. Our product engineers are problem-solving specialists, designing crushing surfaces to handle oversize material, break up slabby material

Learn MoreAR Steel Crusher Liners - Crusher Wear Liner Supplies | Ford Steel

Ford Steel offers Wearalloy 400, 450, 500, Nickel Chrome Plus Plate and Mangalloy plate up to 4-inches thick for AR steel crusher liners in impact, jaw, cone and other types of crushers.

Learn More

Leave A Reply