Cone Crusher Liners - Makuri Group

January 07th, 2022. The MAKURI Group New Year Update. The Makuri Group have had a very busy Makuri Technology Pte Ltd of Singapore has completed the 100% acquisition of Mine To

Learn More2022 Bathtub Liners Cost Calculator | Livingston, Montana | Manta

Bathtub Liners Park County Costs. Knowing the bathtub liners Livingston costs is recommended before starting a bathtub liners project. While looking at national averages can give a general idea, such numbers usually do not include factors which may affect the final price, such as local labor hourly rates, material costs and any local permits required for the Livingston bathtub liners project.

Learn MoreCone Crushers | McLanahan

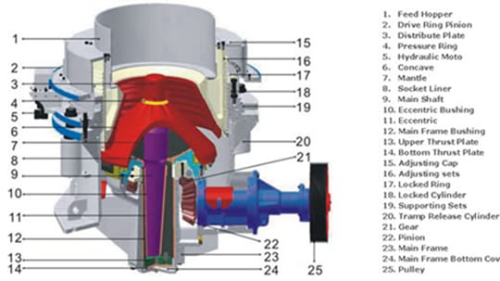

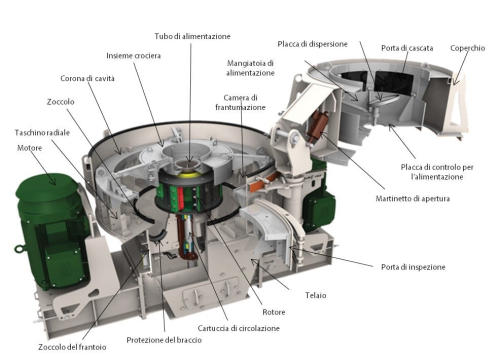

Features & Benefits. A Cone Crusher will deliver a 4:1 to 6:1 reduction ratio. As we set the closed side setting tighter to create a finer output, we also reduce the volume or throughput capacity of the machine. Generally speaking, multiplying the closed side setting by two is a good guide to the top size of the gradation exiting the machine.

Learn Morecone cursher liner | spare bronze casting of impact coal crusher

S6800 Bowl Liner/concave And Mantle Cone Crusher. Crusher Liners - China Luoyang Hengin Heavy Industry. and Cone Crusher Liners material is high manganese steel. After water toughening, a single austenite structure with excellent toughness and non-magnetic properties can be obtained. Its characteristic is that under the

Learn MoreResearch on the Wear Behavior of the Fixed Cone Liner of a

4−7) The frequent replacement of the fixed cone liner not only affects the working efficiency of the cone crusher, but also costs a lot of

Learn Morecone cursher liner | factory sale hammer crusher spare locating bar of

Resminer Cone Crusher Liner - Supplier and Manufacturer in. Manganese Bowl Liners (aka. manganese liners) are one of the widely used wear liners for cone crusher equipment in various applications, including aggregate production, mining, recycling, etc. This type of liner material (steel) does not require heat treatment because it is usually

Learn MoreCrusher Liners - Luoyang Hengin Heavy Technology Co., Ltd

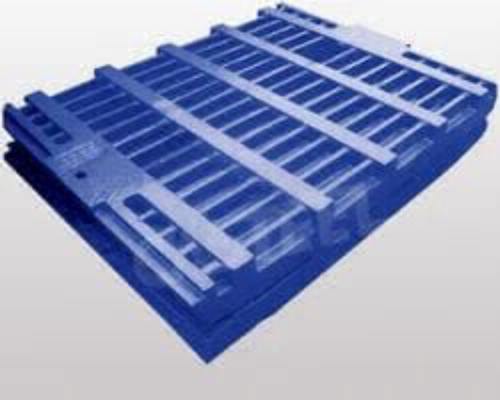

HENGIN'S OEM Crusher Spare Parts products include hydraulic cone crusher, jaw crusher, gyratory crusher main frame, adjusting ring, copper sleeve, bearing,

Learn MoreCrusher Liners | Cone Crusher Liners | Crushing Wear Parts

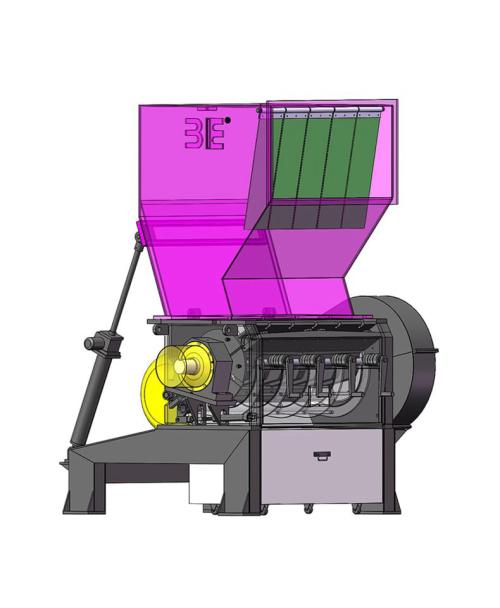

Crusher Liners CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years' experience supplying crushing wear parts to global mining and mineral processing, oil sands, steel, cement, power and aggregate customers.

Learn MoreLiner Replacement For Cone Crusher - How simple it is!

Leading Crushing and Screening Equipments Manufacturer in Korea.

Learn Morebowl liner for cone crusher | crusher eccentric wearing plate australia

Cone crusher parts : Bowl Liner and Mantle Crusher wear. Cone Crushers for Mining: Cone Crusher Bowl Liners and Mantles for Extreme Conditions Because of the extreme crushing conditions experienced by the crushers used in mining operations, special attention must be paid to the materials used in producing these castings. h6800 series cone

Learn MoreHigh Manganese Bronze Casting Cone Crusher Spare Parts Socket Liner

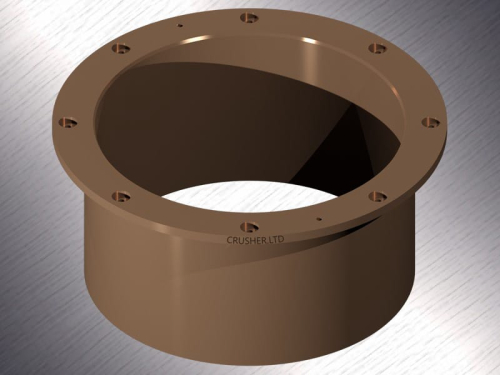

High Manganese Bronze Casting Cone Crusher Spare Parts Socket Liner Bronze is one of the most important material of Crusher Machine Parts,The raw material is high-lead bronze with good property of self-lubrication, which helps to prevent the machine from locking and being damaged when the lubricating oil can't be supplied steady.

Learn MoreCone Crusher Liners Selection - Wear Parts For Industry - Qiming Casting

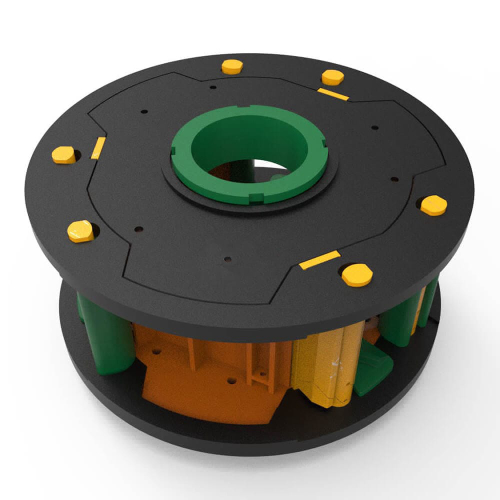

2.Crusher Liner's Material Cone crusher wear parts, concave and mantle, are casting by manganese steel. Mangalloy, also called manganese steel or Hadfield steel, is a steel alloy containing an average of around 13% manganese. Mangalloy is known for its high impact strength and resistance to abrasion once in its work-hardened state.

Learn Morecone cursher liner | grasslands countershaft bushing mill

Cone Crusher Liners - EB Castworld % Cone Crusher Liners. Cone Crusher Liner has the characteristics of beautiful appearance, high internal quality, resistance to emptiness, wear, extrusion, and long service life. It fully meets the requirements of the concentrator for the use of Cone Crusher Liner: Cone

Learn MoreBowl Liner & Mantle | Wear Resistant Crusher Parts - GTEK

And the bowl liner which is also known as cone crusher concave, is the sacrificial wear liner which sets inside the upper frame for protecting the upper

Learn MoreWhen to change Cone Crusher liners - Cast Steel Products

Depending on the application, If the Cone Crusher liner is wearing evenly throughout the chamber, when it has worn down to about 1” (2.5 cm) thick at the bottom it is generally time to consider changing it. At about 3/4” to 5/8” (1.9 cm to 1.6 cm) thick, the liner will crack, causing the backing material to begin to disintegrate.

Learn MoreProlonging Cone Crusher Liner Life - Agg-Net

Cone crushers operate by having stone fed into the top of the crusher chamber. The chamber is lined with wear parts, namely the mantle and bowl liners.

Learn MoreCone Crusher Cavity Types And - Qiming Machinery

The most important factor in Cone Crusher liner selection is the feed. Cone Crusher Cavity Types. You should have a well-graded feed going into the crushing chamber. A well-graded feed is generally considered as: 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two.

Learn MoreCone Crusher Liners - EB Castworld % Cone Crusher Liners

EB uses Mn13, Mn13Cr2, Mn17Cr2, Mn18, Mn18Cr2 to produce Cone Crusher Liners according to the customer’s working environment to effectively prevent the wear during the crushing

Learn MoreCone Crusher Liners: What To Choose And When To Change - KeepandShare

Cone Crushers are equipped with crushing chambers. It is the space between the concaves and mantle, which is the moving piece of steel. Concaves and mantles are protected from daily wear by replaceable manganese liners. Selecting a Cone Crusher liner There are numerous liners for both fine and coarse feeds.

Learn MoreCONE CRUSHER LINER

Cone Crusher Liners Key words: Mantle, Bowl Liner, Concave Permanscess has been providing premium manganese steel and hight chrome crusher liners for decades. our liners have been proven in mining and aggregate production to achieve and often exceed the performance of the equivalent castings supplied by Original Equipment Manufactures.

Learn MoreCone Crusher Liners | Crushing Wear Parts

Our CSP Crusher wear liners offering covers major gyratory crushers, jaw crushers, cone crushers, impact crushers and roll crushers – optimized for any size

Learn MoreHP100™ cone crusher - Outotec

Less downtime, more confidence. HP100™ cone crusher delivers less downtime and increased operator confidence. Dual-acting hydraulic tramp-release cylinders are used to let the crusher pass tramp iron and to provide a large clearing stroke if needed. The double accumulator combination provides better reactivity of the hydraulic system.

Learn MoreCone Crusher Liners Selection - Wear Parts For Industry | Qiming

2.Crusher Liner’s Material. Cone crusher wear parts, concave and mantle, are casting by manganese steel. Mangalloy, also called manganese steel or Hadfield steel, is a steel alloy

Learn MoreCone Crusher Wear Parts - Columbia Steel Casting Co., Inc

For better production and longer wear life, choose Columbia cone crusher liners. · Standard, heavy-duty, and custom wear parts for all popular cone crushers.

Learn MoreManganese Mantle Bowl Liner Suit Cone Crusher Wear Parts T900

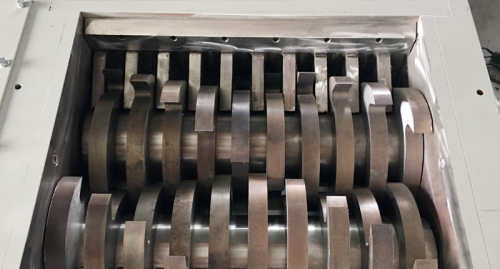

Manganese Mantle Bowl Liner Suit Cone Crusher Wear Parts T900. Hyton produce High manganese casting liners mainly include Mantle, Bowl Liner, Feed Cone , jaw plate, check plate, Arm Liner , Steel Ball ,and etc.. Cone Crusher Spare Parts-Cone Concave Advantage and Features. 1. Use: Wear parts for crushers in the quarry, mining, cement, aggregate, recycling, shredding and demolition

Learn MoreCone Crusher Liners For Popular Brands With Various Material

Cone crusher concave, which sits in the upper frame of the crusher to protect it from wear. It is the outer sacrificial wear liner that sits inside the upper frame. Common Aliases: Cone crusher

Learn MoreCone Crusher Mantles & Bowl Liners - Optimum Crush

Optimum Crush has the highest quality cone crusher mantle & bowl liners available! Optimize your mining with our custom engineered products.

Learn MoreCone Crusher Liners | Manufacturing and service of

We understand that to keep your equipment and process running smoothly, it may require an approach that is more in-depth than just choosing a different material grade or Cone Crusher

Learn MoreCS Series Cone Crusher Liners - Hunan JY Casting

Experience customer support beyond what you'd get from ® crusher dealers. Hunan JY Casting offers high-quality CS series cone crusher liners for your ® crusher-guaranteed to perform as well as (or better than) OEM crusher parts. Hydroset™-style crushers have been around for decades. As the brand names have changed

Learn MoreCone Crusher Bowl Liner, 442.8249 - Pinterest

Qiming Machinery manufactures the aftermarket cone crusher bowl liner (Part number: 442.8249, Weight: 622kg )for the customer who uses the CH430 cone

Learn MoreEXCEL™ Crusher Liners for ® MP™ series crushers

We manufacture MP® cone crusher liners. A large copper mine in South America contacted us for assistance with their pebble crusher. The mine operates a MP

Learn More

Leave A Reply