Gyratory Crusher - Mining Fundamentals

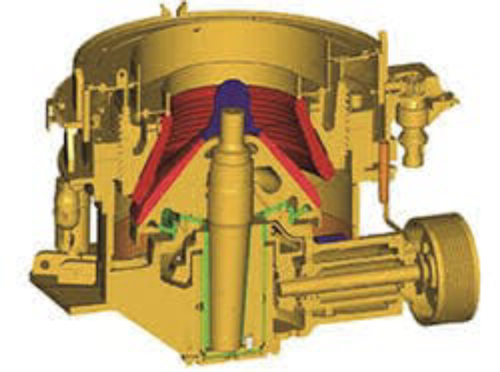

A gyratory crusher is an ore processing machine that crushes the ore between an eccentrically mounted cone and a crushing throat,

Learn MoreGyratory Crusher HOW IT WORK

how a gyratory crusher works | Crusher Solutions Gyratory and cone crushers work in pretty much the same way, although they have slightly different designs. how a gyratory

Learn MoreTag Archives: gyratory crusher - International Mining

The jaw gyratory crusher is characterised by an especially enlarged feed opening, according to thyssenkrupp. It is normally serrated and, together with the

Learn MoreGyratory Crusher (TS) for harsh environments

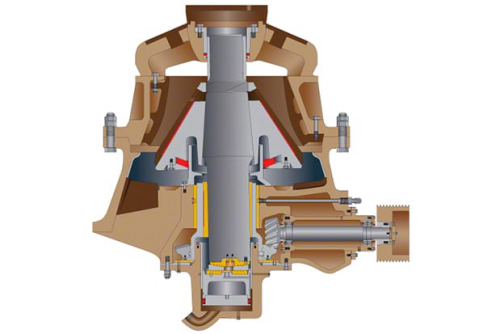

The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions. It is designed so that you can easily access and remove the eccentric assembly, bushings and hydraulic piston through the top of the crusher, hence the name

Learn MoreGyratory Crusher

HGT Hydraulic Gyratory Crusher is a primary crusher integrated mechanical, hydraulic, electrical, automated and intelligent control together. And the automatic control system is the greatest feature, makes operation more convenient.

Learn MoreWhat Type of Crusher Is Best for Primary Crushing?

Gyratory Crushers are an excellent choice for a primary crusher, as they can handle very hard and abrasive material. They are ideal for dry

Learn MoreJaw Crusher VS Gyratory Crusher - JXSCMACHINE

The gyratory crusher is taller than the jaw crusher, thus needs a high workshop design. Besides, gyratory crusher is heavy than jaw crusher, it's not convenient to move. Capacity. Gyratory crusher can work continuously, has high productivity and crushing ratio ( up to 6-9.5), working performance is very stable, light vibration.

Learn MoreGyratory Crushers - Sandrock Mining

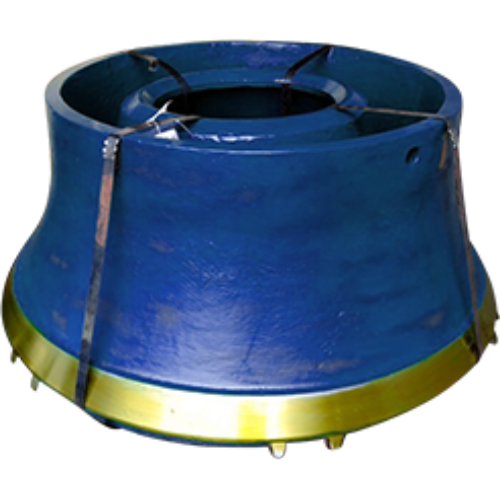

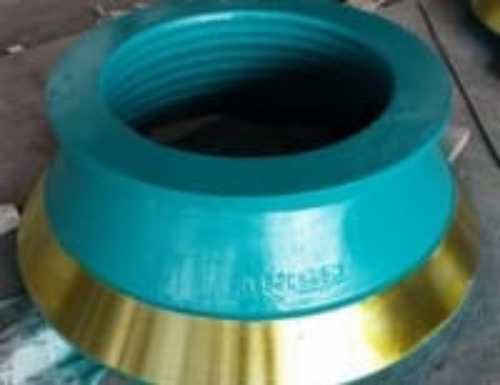

Gyratory Crushers. Sandrock Mining Gyratory crushers are frequently used in the primary crushing stage and a little less often in the secondary stage. Gyratory crushers have an oscillating shaft. The material is reduced in a crushing cavity, between an external fixed element (bowl liner) and an internal moving element (mantle) mounted on the

Learn Moreconstruction of gyratory crusher

15/09/2022 · WhatsApp: https://wa.me/8613621919955?text=Pls+send+us+this+message+first%2C+then+we+will+arrange+for+the+right+sales+engineer+to+serve+you%21+Your+Unique+Co

Learn MoreGyratory Crusher Services I Service - thyssenkrupp Mining Technologies

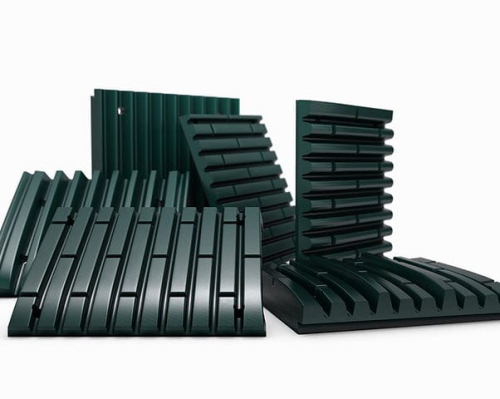

Detect and rectify faults at short notice through the analysis of your plant's operating and process data. Visualization of crusher KPIs and analytics results (trends, prognosis, machine conditions, wear analysis and more) Identify process and operation improvements. Benchmarking for evaluation of improvement potentials.

Learn MoreGyratory Crusher & Cone Crusher Mantle Differences

25/07/ · While the Secondary and the Tertiary crusher’s travels between 500-600 R.P.M. This difference in the speed results in a HAMMERING type crushing action over the SQUEEZING

Learn MoreHow Gyratory Cone Crusher Works | Crusher Mills, Cone Crusher, Jaw Crushers

Gyratory Crusher,Cone Crushing Plant,Gyratory Breaker-Cone But strictly speaking, gyratory crusher and cone crushers are not the same. Each crusher is designed to work with a certain maximum size of raw material,

Learn MoreGyratory Crusher How It Works

Gyrating crusher broken cone of the cyclic movement of the cone cavity within the shell, squeeze the material, splitting and bending, rough chopped . What Is The Working Principle of Gyratory Crusher? - Crusher FAQ. When it comes to Replacement Gyratory Crusher Parts, Excel has been crushing the market for decades.

Learn MoreCG830 Gyratory crusher — SRP - rockprocessing

CG830i crusher offer excellent reliability and safer & faster maintenance – up to 30% faster than competing crushers. A robustly designed one-piece main

Learn MoreGyratory Crusher Explained - saVRee

Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly referred to as a ‘Gate’s crushers’ in the early years). A primary

Learn MoreMethod for securing a gyratory crusher mantle - Google Patents

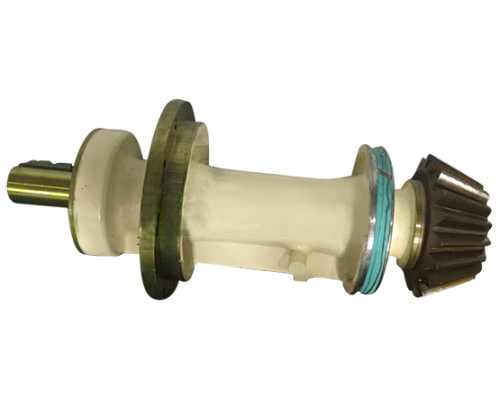

The head nut assembly for gyratory crusher which includes a shaft having a lower portion, a tapered middle portion and a threaded upper portion.

Learn MoreGyratory Crusher | Hazemag North America

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the

Learn MoreHeavy duty, maintenance-friendly Gyratory Crusher

High-power crushing and easy maintenance with the Gyratory Crusher NT Get the best features of the previous model with added safety and usability functions.

Learn MoreIndustrial Solutions Gyratory crushers - ThyssenKrupp

Jaw gyratory crushers – design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The

Learn MoreWhat The Difference Between Cone Crusher And Gyratory

The Gyratory crushers are similar to cone crushers but they are different.Bebon heavy industry is a Gyratory crushers manufacturer as well as cone crusher difference between gyratory and jaw crusher -

Learn MoreThe Features and Differences between Jaw Crusher and Gyratory Crusher

d. It is required to feed the ore with a uniform particle size, otherwise the crusher is easy to be blocked, and the miner must be set before crushing. e. It is suitable for crushing massive ore, and sometimes the discharge particle size is too large for strip or flake ore. (A jaw crusher works in Morocco's 500tpd silver ore dressing plant)

Learn MoreWhat Is Gyratory Crushers

Gyratory Crushers. Gyratory crushers feature a conical head and concave surface (often lined with manganese steel) and break apart material by compression through what is known as eccentric movement. Like jaw crushers, gyratory crushers are often utilized in primary crushing stations, though they may sometimes be used as secondary crushers

Learn MorePrimary gyratory crusher parts - Outotec

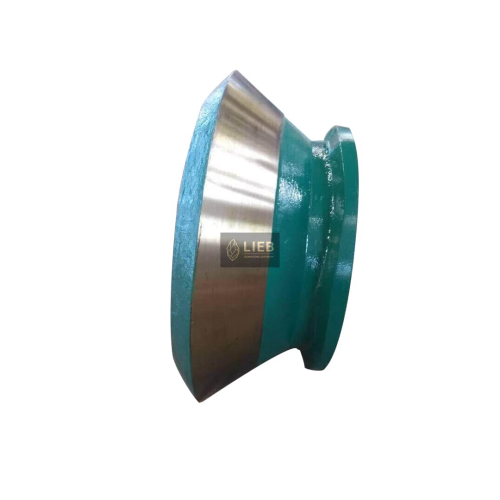

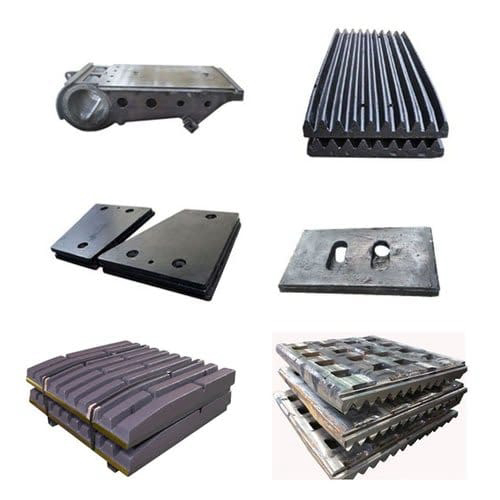

Primary gyratory crusher parts Improve crushing performance and prolong service life Wear parts High-quality primary gyratory crusher parts increase the crushing performance and reduce unexpected downtime. We offer standard or tailor-made parts according to your application requirements. OEM quality

Learn MoreGyratory Crusher Operation - Mineral Processing & Metallurgy

18/07/ · Gyratory Crusher Operation. Crusher are used to reduce the ore in size, the purpose and the responsibility of the crusher operator is to operate that crusher in such a manner as to

Learn MoreCrusher Close Side Settings - Mineral Processing & Metallurgy

17/01/ · Crushing angles may vary between the approximate limits of 22 and 30 degrees in a line of standard gyratory crushers. It is possible to use larger angles in the larger sizes of crushers because the greater weight of the individual pieces of material tends to minimize slipping. In these large machines, a difference of a few degrees in the

Learn MoreTorque Analysis of a Gyratory Crusher with the Discrete

Gyratory crushers are the most common ma- chine used in the primary crushing in the copper mining industry of Chile and worldwide, and they are

Learn MorePDF Industrial Solutions Gyratory crushers - ThyssenKruppPDF

Jaw gyratory crushers - design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The

Learn MoreGyratory and Cone Crushers - Mineral Processing & Metallurgy

21/11/ · Gyratory crushers and cone crushers, while looking the same and performing similar duties, are two different machines.A quick look at a machine will allow you to determine

Learn MoreGyratory Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

Gyratory Crusher: Introduction The design of the gyratory crushers and jaw type gyratory crushers is based on more than one hundred years of experience of . US Patent # 5,718,390. Gyratory crusher – Patents.com. A gyratory crusher includes a flexible dust seal having an outer edge attached to a cone head of the crusher and to an outer of a

Learn MoreSuperior™ MKIII Series primary gyratory crushers

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. Outotec's Superior™ MKIII primary gyratory crushers

Learn MoreHow A Gyratory Crusher Works

Crusher & Grinder « Novamining. What is a Cone Crusher and how it works? The cone crusher is a modified version of gyratory crusher. The essential difference is that the shorter spindle of the cone

Learn More

Leave A Reply