Apron Feeder Maintenance Pdf

apron-feeder-maintenance-pdf 2/15 Downloaded from thesource2.metro.net on May 31, 2022 by guest graphs. The Aggregates Handbook, Second Edition National Stone, Sand & Gravel Association 2013-03-20 Food Code United States. Food and Drug Administration X-Ray Equipment Maintenance and Repairs Workbook for Radiographers and Radiological

Learn MoreEvolution of Design and Applications of Apron Feeders

3 AN APRON FEEDER IS A MECHANICAL FEEDER USED TO EXTRACT RAW MATERIAL TYPICALLY FROM OWNER S MANUAL Model MH1230 Important Safety Instructions Assembly

Learn MoreAGGRETEK heavy duty apron feeders

Because of their durable, long life components, our apron feeders are low maintenance even under severe conditions. Optional Dribble Conveyor. As an optional

Learn MoreAn expert insight into apron feeder evolution - Quarry Magazine

Apron feeders are robust machines that are designed for long-term use in need to lift heavy rollers manually when servicing the machine.

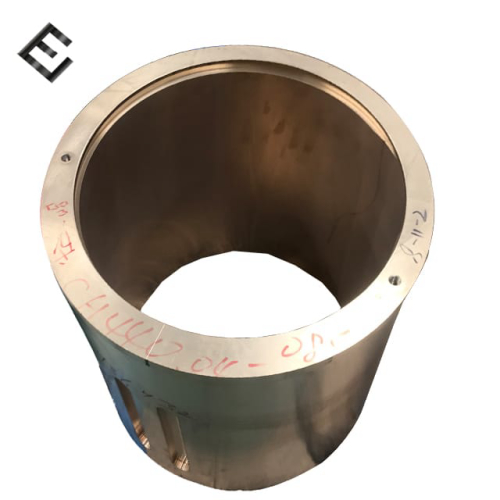

Learn MoreApron feeder parts - Outotec

All Outotec apron feeder parts are designed to meet the precise specifications of the components of your feeders. Original equipment replacement parts ensure proper fit and

Learn MoreDocs - Aumund - Ademin-Met

1 Apron Feeder Retrofit . 2 CENTREX® EN 3D Animation . 3 Pan Conveyor . 4 Samson® Feeder . 5 Storage & Discharge Equipment . 6 BEW BL - Rotary Discharge Machine

Learn MoreHow to clean the bottom of Apron Feeder

2.The viscous material --CLAY Apron feeders is running with material, the material runs to the head and falls down, a part of the material is unloaded, and some materials are stuck on the chain plate continue to run. When the clay on the chain plate accumulates to a certain amount, the weight of the chain plate increases.

Learn MoreHow to clean the bottom of Apron Feeder

2.The viscous material --CLAY Apron feeders is running with material, the material runs to the head and falls down, a part of the material is unloaded, and some materials are stuck on the

Learn MoreApron feeder upgrades

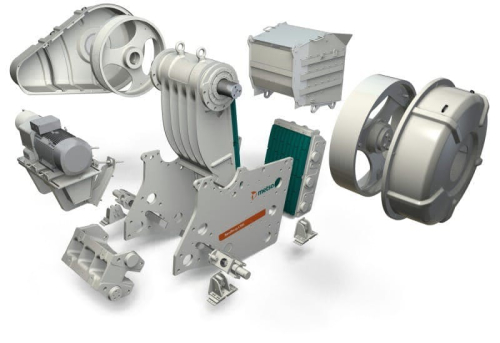

Generally, apron feeders are a high-torque low- speed application, and many older models use multiple reducers, chain and sprocket sets, open gearing, countershafts, etc., to achieve the necessary mechanical advantage. Spare parts inventory requirements are high and older parts can often become obsolete and difficult to source.

Learn MoreReliability centered maintenance: apron feeders - Assetivity

Let's use the example of apron feeder maintenance to illustrate how you might develop a better maintenance strategy for your key assets.

Learn MoreDocs – Aumund – Ademin-Met

1 Apron Feeder Retrofit 2 CENTREX® EN 3D Animation 3 Pan Conveyor 4 Samson® Feeder 5 Storage 6 BEW BL - Rotary Discharge Machine SAMSON 1 Eco Hopper - C

Learn MoreMAF SERIES APRON FEEDERS

APRON FEEDERS TECHNICAL SPECIFICATIONS www.mekaglobal.com >> At specified inclination and 1.6 t/m3. Capacities depend not only on feeder size but also on feeder inclination, feed gradation, etc. Feeders can be supplied in lengths to suit

Learn MoreFEED TUBE CLAMP BLOCK | apron feeder maintenance manual

HSK TOOLING SYSTEM. Please rotate the clamping ring counterclockwise more than 360 Coolant tube is included. Super Tite-Lock Milling Chuck (High-Balanced Type ).

Learn MoreApron feeder installation and management - Outotec

Apron feeders in mining need to be installed correctly with proper upkeep to maintain a high. Apron feeders require proper installation and

Learn MoreApron feeders - Automation - PDF Catalogs | Brochure

custom-designs and manufactures durable accessories to last the life of your feeder while requiring minimal maintenance or added costs. Drive Units A wide

Learn MoreApron feeders - RCR Mining Technologies

RCR MT Apron Feeders are recognised throughout the industry for their robust design and low maintenance requirements.

Learn MorePDF Apron feeder upgrades - MetsoPDF

Apron feeder upgrades Significantly improve reliability, maintenance, efficiency, and safety with our range of customized retrofit solutions. The Outotec solution Outotec can help you understand which parts on your apron feeders are worn, prone to failure, or need immediate attention. We can also recommend upgrade

Learn MoreTAKRAF APRON FEEDER

Our continuously expanding reference list demonstrates that owners and TAKRAF Apron Feeders are designed for demanding material handling work in mineral

Learn MoreApron Feeders - TAKRAF

TAKRAF delivered the apron feeder as part of the fully mobile crawler-mounted crushing plant BRF-W2-10000 for the Clermont coal mine in Australia. The apron feeder receives the material by shovel and feeds the crusher of the mobile plant. Project figures 10,000 t/h Efficiency

Learn MoreAPRON FEEDER - Elecon

APRON FEEDER. Suitable for most robust applications and for absor heavy Impact Loads. ELECON has supplied appron feeders with capacity upto 3000 TPH and

Learn MoreApron Feeder - Austmine

Optimising maintenance. Eliminating downtime. Using Less rollers. $40.40 per roller p.a. Purchase. $34.40. Avg

Learn MoreQE330-Fintec-640.pdf - Crusher Works

All data and information in this manual may be changed without further Apron Feeder . in the operating and maintenance instructions.

Learn MorePDF Industrial Solutions Apron feeders - ThyssenKruppPDF

Apron feeder RKF 2.2 x 15.8 - D8 with inboard chain Apron feeder RKF 3.4 x 17.0 - D9 with outboard chain Apron feeders are designed for conveying capacities of more than 14,000 t/h and can be integrated into stationary, semi-mobile or mobile plants. Stationary single-shaft impact crusher (right) fed by two apron feeders

Learn Moreapron feeder maintenance manual

apron feeder - - free download as pdf file (.pdf), text file (.txt) or using long life components, jaques apron feeders provide low maintenance refer to the appropriate operators

Learn MoreApron feeders - Automation - PDF Catalogs | Technical

Dribble Drag/Belt Conveyors When required for cleanup, feeders Open the catalog to page 6. Expect results to help them reach their goals. Minerals Industries, Inc., 4000 Town Center Blvd., Ste. 400, Canonsburg, PA 15317, USA, tel +1 412 269 5000, fax +1 412 269 5161, www.metso.com. Open the catalog to page 8.

Learn MoreApron Feeders - Aumund

Apron Weigh Feeder DPB The possibility of combining material extraction from the hopper, weighing and metering in one machine. For applications where usage of belt weigh feeder is

Learn MorePDF Minerals Processing Systems D SERIES APRON FEEDERSPDF

D Series apron feeders are low maintenance even under severe conditions. MOVE MOUNTAINS ®Jaques D Series Apron Feeders • Capacities up to 14,500 mtph (16,000 tph) • Custom designed for any application • Variable speed optimises plant capacity • Proven design based on crawler tractor components

Learn MoreApron Feeders Australia | Apron Feeder Parts, Pans & More - Minprovise

Our improvements have allowed us to complete these apron feeder change-outs 36 hours early. Contact Us To find out more about the range of apron feeder, pans, parts and chains we can supply, fill out the contact form below. Alternatively, contact us on (08) 9359 6800 today.

Learn MorePDF Conveying Equipment Apron Feeders - dokaendustri.com.trPDF

A. Throat opening should be at least 2.5 times the maximum lump size. B. Clearance under strike off point should be at least 1.5 times the maximum lump size. C. Headshaft location to prevent material flow when it is not running should be 18" past the repose angle (angle R) immediately outside the bin opening. D.

Learn MorePDF Handbook of Cots and Aprons Installation and Maintenance - InarcoPDF

Maintenance of Aprons - a few suggestions Do not change top and bottom aprons together Use apron size recommended by OEM only Use traverse motion 8-10 mm and check it regularly Traverse motion with minimum dwelling time is always beneficial since apron wear out will be less Wash aprons in lukewarm soap solution and rinse with water thoroughly

Learn MoreIndustrial Solutions Apron feeders - ThyssenKrupp

Apron feeder RKF 2.2 x 15.8 - D8 with inboard chain Apron feeder RKF 3.4 x 17.0 - D9 with outboard chain Apron feeders are designed for conveying capacities of more than 14,000 t/h and can be integrated into stationary, semi-mobile or mobile plants. fed by

Learn More

Leave A Reply