Jaw Plates | Jaw Dies - Crusher Wear Parts

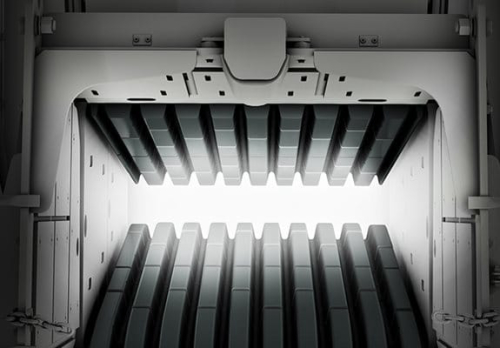

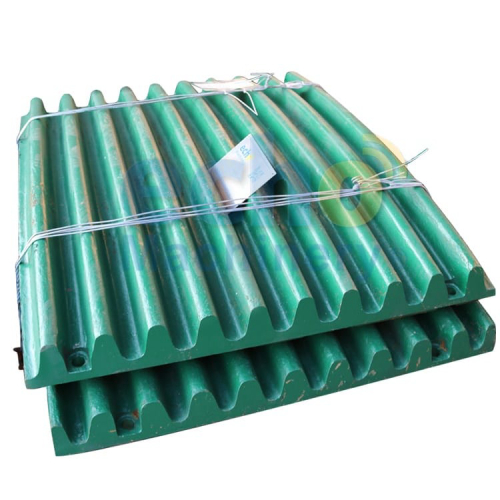

A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw). Compression of material undergoing crushing in a jaw crusher

Learn MoreCrusher Jaw Plate Latest Price, Manufacturers & Suppliers

We are the renowned company in offering Jaw Crusher Plate to our clients. This product is widely appreciated in the market for high strength and resilience.

Learn MoreJaw Crushers | McLanahan

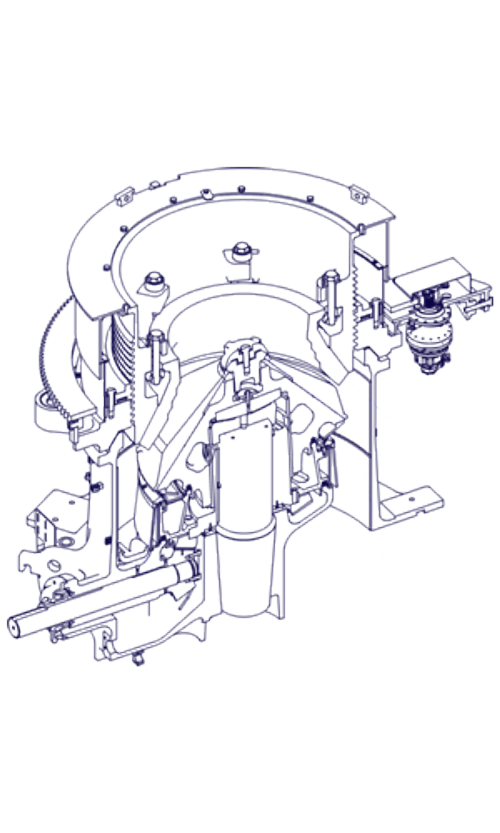

H-Series Jaw Crushers still use a toggle plate that has the dual purpose of transferring the crushing action and a fuse to protect the crusher's major components. Also used are off-the-shelf bank hydraulic cylinders which provide for tramp iron relief with auto-reset to the last stored set point of the closed side setting.

Learn MoreCrusher Jaw Plates For Popular Brands By Hunan JY Casting

Premium Crusher Jaw Plates. The crusher jaw plates are the main wear-resistant parts installed on the machine body to squeeze and crush the stone. Normally, it consists of a 1 piece fixed

Learn MoreJAW PLATES - Precision Casting

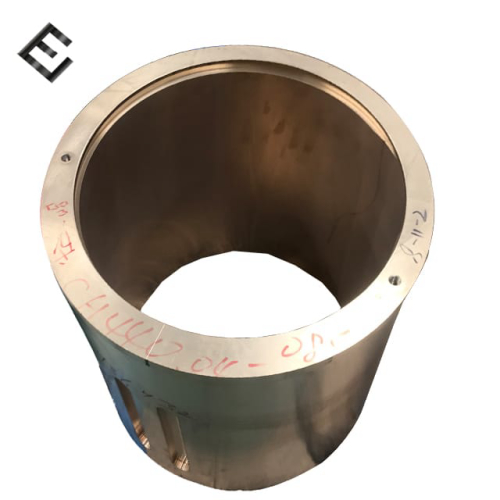

Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing

Learn MoreJaw Plate, Teeth Plates, Jaw Crusher Wear Parts for Sale - Willing

Jaw Plate – Jaw Crusher Wear Parts. Jaw Plate is the main wear part of Jaw Crusher, including fixed plate and jaw plate . We can produce a variety of meet the requirements of the jaw plate

Learn MoreResminer Stone Crusher Jaw Plates - Wear Resistance Supplier in China

The pattern of stone crusher jaw plate was used in this process to achieve the shape of the stone crusher jaw plate. Pouring Melted Chemical When the raw material turns into liquid, it will be transferred to the machine outlet to get the desired shape. Heat Treatment Process A modern and high-tech furnace machine is used in this procedure.

Learn MoreJaw Crusher Components & Parts - Mineral Processing & Metallurgy

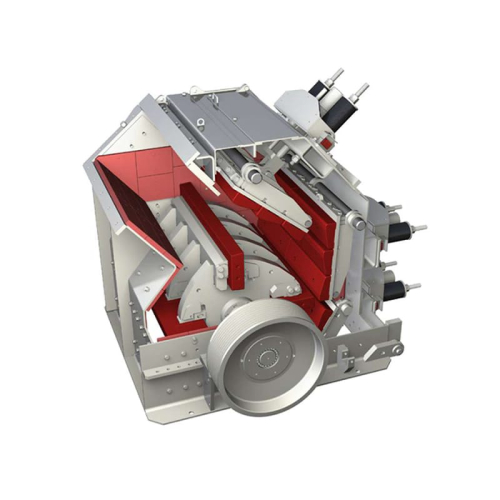

Jaw Crusher Parts. Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel. These are the parts and components that generate the crushing action and provide the energy needed to break the ore. Let's follow the chain of events within a crushing cycle to see how

Learn MoreHow to Choose the Right Jaw Plates for Jaw Crushers - Ware Resistance

A jaw crusher crushes stone or ore using large steel crushing plates (jaw plates) that move in two converging tracks with an adjustable gap width. Raw material enters at the top of these tracks, and as it slides down, it is squeezed by these plates until finally getting jammed as its size prevents further convergence.

Learn MoreMaterials of Jaw-crusher plates and application of Bi-layers

The present paper reviewed the various metal materials for the Jaw-crusher plate used currently in the related machines abroad and domestic,

Learn MoreJaw Plates - SHANVIM

JAW CRUSHER PLATE-JAW LINER. Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time. A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw).

Learn MoreChina Jaw Crusher Accessory Deflector Plate, Jaw Crusher

China Jaw Crusher Accessory Deflector Plate manufacturers - Select 2022 high quality Jaw Crusher Accessory Deflector Plate products in best price from certified Chinese Accessory Equipment, Metal Accessory suppliers, wholesalers and factory on

Learn MoreJaw Crusher - an overview | ScienceDirect Topics

Rose and English [9] determined the capacity of a jaw crusher by considering the time taken and the distance travelled by the particles between the two plates after being subjected to repeat crushing forces between the jaws. Therefore, dry particles wedged between level A and level B (Figure 4.4) would leave the crusher at the next reverse movement of the jaw.

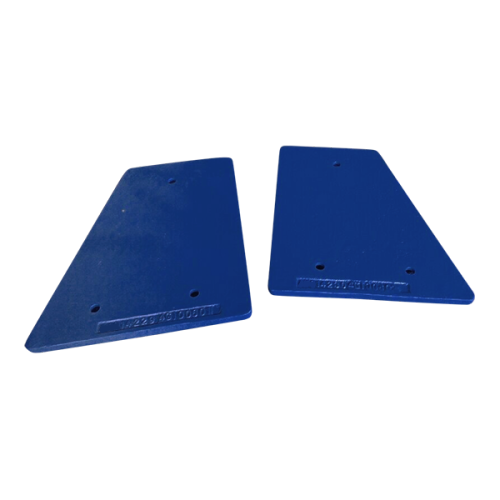

Learn MoreKenco Longer Wearlife Parts | Jaw Cheek Plates

Jaw Crusher Cheek Plates Kenco Engineering tungsten carbide impregnated Cheek Plates provide the solution to wear problems encountered with jaw-type crushers.

Learn MoreJAW CRUSHER SERIES

The nip angle is the angle between the fixed and moving jaw plates. Our CJ crushers have an optimum nip angle in the 16-23 degree range.

Learn MoreJaw Crusher Plate manufacturers & suppliers

Jaw Crusher Plate manufacturers & suppliers ; US$ 1.4-1.9 / kg. (FOB Price). 10 kg (MOQ) · ISO 9001: · High Manganese Steel ; US$ 1.55-1.89 / kg.

Learn MoreJaw Crushers - MEKA Crushing & Screening Plants

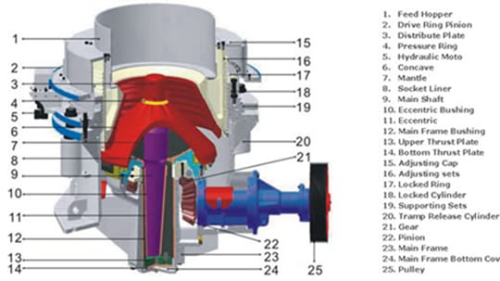

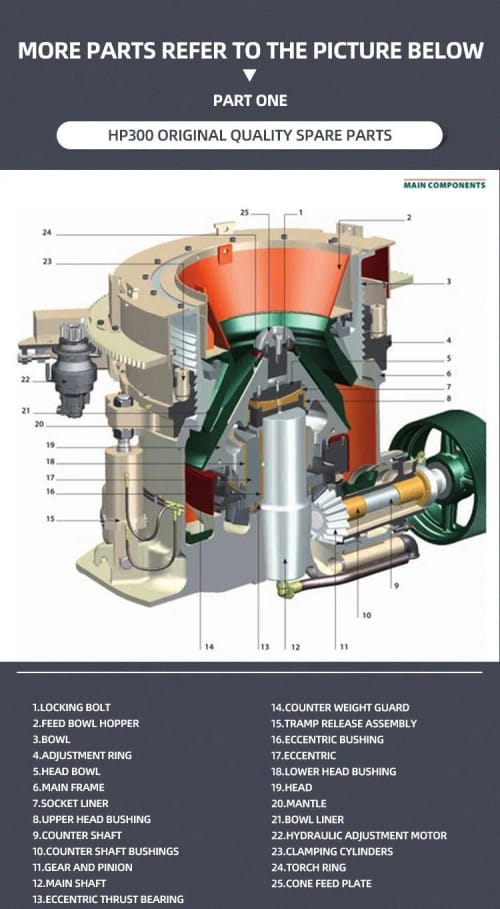

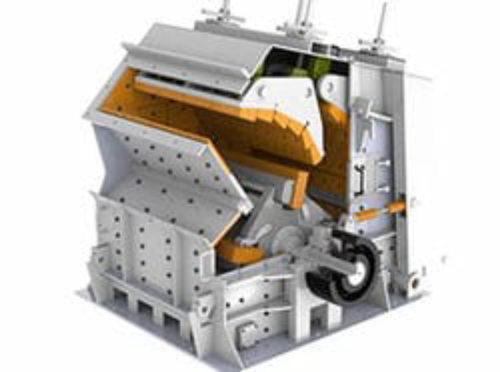

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds

Learn MorePDF JAW CRUSHER SERIES - Mining and Rock TechnologyPDF

Jaw crushers are normally capable of a reduction ratio of 1:2 or 1:3. This ratio is affected by the feed material's bulk density, crushability, size distribution and moisture content - among other factors - and will affect the crushing chamber performance. The nip angle is the angle between the fixed and moving jaw plates. Our CJ

Learn MoreWhat happened? Jaw plates which need to change frequently for jaw crusher!

Our replacement jaw feature in three grades depending on the crushing conditions encountered 13%MN, 18%MN, 21%MN. BDI's replacement jaws offer to wear life and fit and go through a rigorous quality control process. Benefit: Proprietary alloys offer increased toughness and durability. Better fit for quick and easy replacement

Learn MoreJaw Plate - Toughing Crusher

Additional information. Introduction:Jaw plate is the main wear part of jaw crusher, which is divided into moving jaw plate and fixed jaw plate TOUGHING’s jaw plate and cheek plate is

Learn MoreJaw Plate Crusher Jaw Plate Price Discount - EB Castworld

The jaw plate is made of new high manganese steel, super high manganese steel, Super high manganese steel and other materials are suitable for jaw crushers of various specifications. The jaw crusher is composed of a working cavity composed of movable and fixed jaws.

Learn MoreC160 Crusher Jaw Plates - Hunan JY Casting

When it comes to C160 crusher jaw plates, Hunan JY Casting focuses on manufacturing those wear parts for a long time.

Learn MoreCrusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 28 Listings

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn MoreCrusher Parts Jaw Plate Tooth Plate Suit for C125 Jaw Crusher

Certification: CE, RoHS, ISO 9001:2000, ISO 9001: Standard: ASTM Surface Treatment: Polishing Manufacturing Process: Casting Material: High Manganese Steel Descripition: Crusher Jaw Plate

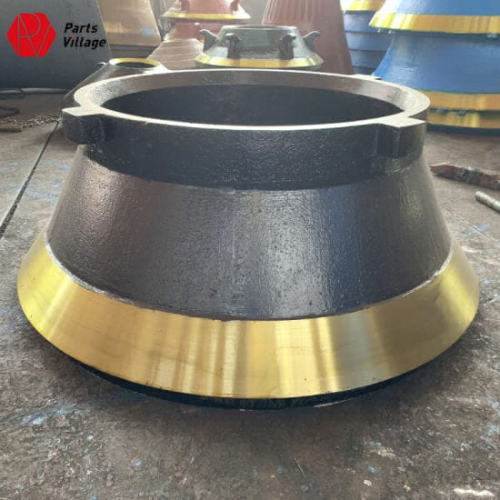

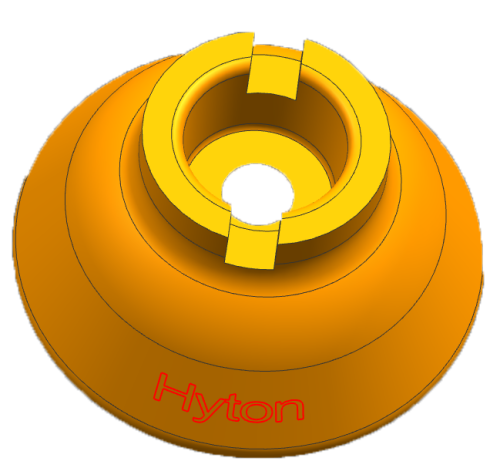

Learn MoreJaw Plate Manufacturer | Bowl Liner | Blow Bar - Casteel Foundry

Our full-line of products from VSI Parts bucket Teeth ,hammers,blow bars To large Concave, Mantle , Jaw plates, Grates Mill Liners and much more have been highly recognized among customers and used in wide range of applications.

Learn MoreChina JAW CRUSHER PLATE-JAW LINER Manufacture and Factory - SHANVIM

Description Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time. A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw).

Learn MoreJaw Crusher Plate - EB Castworld

The short life of the jaw crusher’s high steel jaw plate has a lot to do with assembly. When assembling, it is generally requested that the jaw plate of the crusher must be firmly pasted on the jaw Crusher plate. At the same time, pay attention to the leveling. When the crusher is working, the jaw plate of the jaw crusher cannot show looseness.

Learn Morecrusher jaw plates At The Best Prices

Jaw Crusher Plate Crusher Jaw Plate High Manganese Jaw Crusher Spare Parts Fixed Jaw Plate And Mobile Jaw Plate. $1,600.00/ Ton. 1 Ton (Min. Order) 2 YRS CN. Supplier. Contact Supplier. Compare. Ad. 1 / 6.

Learn MoreJaw Crusher Wear Parts - Unicast Inc

Increase machine up-time with Unicast Jaw Crusher replacement wear parts including jaw plates, cheek plates, wedges, and toggles.

Learn MoreThe 5 Abrasion Reasons Of Jaw Plates In Jaw Crusher (I

In jaw crusher, the crushing cavity is formed by movable jaw plate and fixed jaw plate. As we know, raw materials are crushed in the crushing cavity, so jaw plates directly contact with the raw material and are easily damaged. In this case, jaw plates are the main wear-resistant parts in jaw crusher and need to be changed regularly.

Learn MoreJaw Crusher Plates - Wear Parts For Industry | Qiming Casting

Our foundry had succeeded to offer jaw plates for crusher, crusher and other famous brands.On the other hand, Qiming Casting also offer a variety of manganese contents, from 14% up to 22% for the more demanding applications. In some means, we also improve material choice and casting technology. Wedges Wedges

Learn More

Leave A Reply