PRODUCTION PROCESS OF SPANNERS – Raman Exporters

PRODUCTION PROCESS OF SPANNERS. RAMAN EXPORTERS endeavors to stay ahead of its peers and competitors by harnessing the sophisticated and state of the art machinery and

Learn MoreAll About Die Cutting (Types of Machines, Tools and Processes) - Thomasnet

Flatbed die cutting, also referred to as steel rule die cutting, is a fabrication process which employs a flatbed die cutting press and custom steel rule dies to convert the material into custom shapes and designs. This process is suitable for processing thicker material, producing larger parts, and completing small orders or short production runs.

Learn MoreSpanner Wrench Forging Process and Closed die Drop Forging Hammer Selection

At present, there are two kinds of wrench spanner manufacturing processes: one is casting, the other is wrench spanner forging process. Is Spanner Wrench Cast or Forged? Spanner wrench casting process. Melt the bar into liquid state, then pour it into the die cavity with spanner shape, and wait for it to solidify to form a complete spanner

Learn MoreCN104625626A - Spanner tool manufacturing method

The invention discloses a spanner tool manufacturing method which mainly comprises the steps of material preparation, initial forging, first end stamping, second end stamping

Learn MoreAdjustable wrenches manufacturing process | IREGA

Manufacturing. Incoming steel. Our high tonnage forging hammers provide us total independence and control of the process. Machining. Our modern CNC machining centers guarantee minimum tolerances, so our wrenches exceed the international ISO and ANSI standards. Heat treatments.

Learn MoreSpanners Tools Manufacturer in India - Ajay Industries

Ajay Industries, the best hand tools manufacturer in India, provide a huge range of spanners that are available in different specifications.

Learn More10 Types of Spanners And How to Use Them - Engineering Choice

5. Box Spanner. Commonly made of steel tubes, the box spanner is typically used for removing spark plugs. They normally feature a six-sided ring-type head that fits the nut that has been pressed out of the steel tube during the manufacturing process. They are turned using a T-bar passed through the two holes in the middle. 6. Combination Spanner

Learn More3 reasons to consider Cloud Spanner for your next project

Spanner offers up to 99.999% availability with zero downtime for planned maintenance and schema changes. Spanner is a fully managed service, which means you don't need to do any maintenance. Automatic software updates and instance optimizations happen in the background. This is achieved without any maintenance windows.

Learn MoreMethod of making a spanner - MyScienceWork

The method (4) of making a spanner (8) according to claim 1, wherein said second end stamping step (44) forms said second arch-shaped part (d2) by pressing said

Learn MoreCN103111810A - Manufacturing process and material of adjustable spanner

The invention discloses a manufacturing process and material of an adjustable spanner blank. The technique comprises the steps that at first aluminium magnesium alloy material are obtained, and an original adjustable spanner blank is cast by a metal mold in the mode of gravity casting; then the original adjustable spanner blank is carried out on heat treatment by a multifunction heat treatment

Learn MoreHand tools machine supplier for pliers adjustable wrench

We are professional hand tools machine supplier around the world, like production line for pliers, adjustable wrench, spanner, socket, screwdriver,

Learn MoreWhat is the best material and manufacturing process for a spanner

What is the best material and manufacturing process for a spanner? Most types of spanner are made using the drop forging process. Steel rods are cut into short lengths, called billets, and each one is passed through an induction heating coil which uses electromagnetism to heat the metal to about 1000 degrees Celsius.

Learn MoreHow to Manufacture Paints? | Business

In traditional varnish manufacture an open kettle is set over a fire in which copal or other natural gum is heated and dissolved in hot oil. Other ingredients such as driers are added and after cooling the varnish is thinned out to a workable consistency with solvent. It is then clarified by gravity settling, straining or centrifugation.

Learn MoreAdjustable wrenches manufacturing process - IREGA

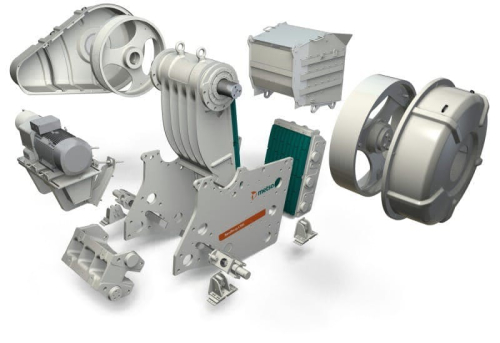

Hot forging gives the shape to our adjustable wrenches. Our high tonnage forging hammers provide us total independence and control of the process.

Learn MoreKR102224191B1 - manufacturing method of spanner - Google Patents

The present invention relates to a method of manufacturing a wrench. Specifically, from the manufacturer′s perspective, the effect of improving the reliability of the product leads to an effect of increasing sales, and from the consumer′s perspective, costs incurred to repurchase the product due to the breakage of the wrench can be reduced.

Learn MoreSpanner Manufacturers & Suppliers - Global Sources Magazines

Spanner USB Flash Drive, Available Flash Memory Capacity of 1/4/8/16/32/64GB. US$ 1.5 - 10 / Piece. 100 Pieces (Min. Order) Lead Time: 7 days. FOB Port: Hong Kong SAR. Inquire Now Compare. We exhibited at 25 Global Sources trade shows View More.

Learn MoreDrop Forging for Spanners

A spanner is a tool used to provide grip and mechanical advantage in applying torque to turn objects—usually rotary fasteners, such as nuts and bolts—or

Learn MoreHow are spanners manufactured? - Wonkee Donkee Tools

Most types of spanner are made using the drop forging process. Steel rods are cut into short lengths, called billets, and each one is passed through an induction heating coil which uses electromagnetism to heat the metal to about 1000 degrees Celsius.

Learn MoreProcess Flowchart | Flow Chart Process Of Spanner Manufacturing

ConceptDraw flowchart maker allows you to easier create a process flowchart. Use a variety of drawing tools, smart connectors, flowchart symbols and shape libraries to create flowcharts of complex processes, process flow diagrams, procedures and information exchange. Process Flowchart | How To Construct A Spanner,

Learn MoreWrenches - Unior Tools

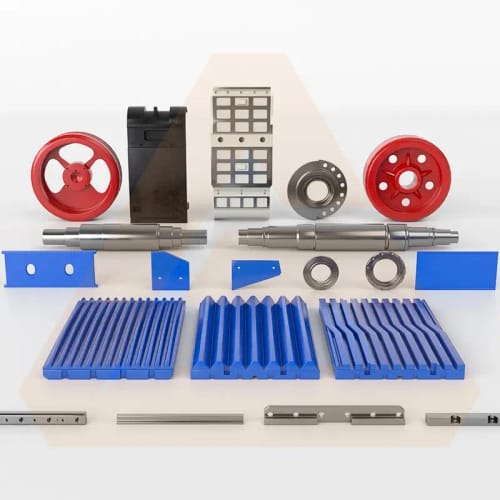

Wrenches · Manufacturing procedure for a combination wrench at Unior · Cutting · Forging · Trimming · Perforation · Burring and grinding · Machine marking and bending:.

Learn MoreMethod of forming socket wrenches - KUC; JOHN

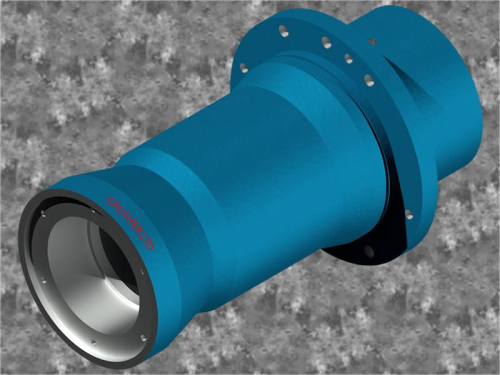

Such prior methods of manufacturing socket wrenches are generally completed in a standard screw machine. These methods include initial insertion of the bar stock into a lathe followed by through openings being drilled and the bar stock generally

Learn MoreWhat is the manufacturing process of spanner? - Fast-Advice

Most types of spanner are made using the drop forging process. Steel rods are cut into short lengths, called billets, and each one is passed

Learn MorePDF Manufacture of hot forged hand tools - GedorePDF

water quenching process, the spanner is reheated and tempered to the correct hardness, which ensures optimum torque and durability. 2 3 4 1 The two-layered nickel/chrome electroplating process provides the spanner with an effective corrosion protective layer, as well as giving it the distinctive GEDORE satin finish. SPANNERS Production of a

Learn MoreManufacturing Infrastructure - Vishal Tools & Forgings

It is a process where the sizes and brand names are mechanically stamped on the wrenches surface. The clearly defined sizes and branding are essential for

Learn MoreUS20030012614A1 - Method for manufacturing a ratchet type ring spanner

A method for forming a cavity in a handle of a ratchet type ring spanner in accordance with the present invention comprises providing a ring spanner having a handle and a head extending from the handle, forming a cutout on a face of the handle, the cutout being communicated with a hole of the head, placing a cutter in the hole of the head, and moving the cutter toward the handle until a shaft

Learn MoreSTAHLWILLE's No 13 spanner

STAHLWILLE's No 13 spanner are made in Germany and are manufactured with thin-walled rings using a special manufacturing process.

Learn MoreBeta Tools combination wrench manufacturing process [English

05/02/ · This is a fascinating look at all the steps in manufacturing the model 42 combination wrench.Beta Utensili, Italy. http://www.beta-tools.itBeta Tools, UK. ht

Learn MoreManufacture of hot forged hand tools

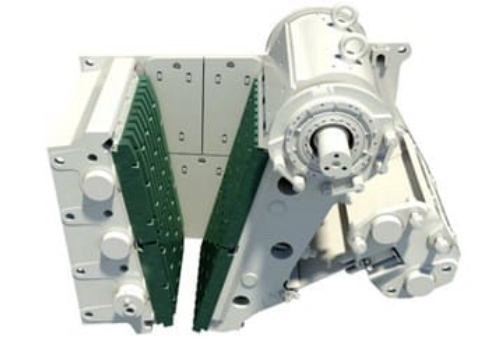

A drop forging process is well suited to produce products such as spanners, pliers and puller yokes. Heated raw material is transformed at high speed in a

Learn MoreAdjustable Wrench Manufacturing Process - Hand tools machine

Spanner Manufacturing Process; Socket Manufacturing Process. Video; News; Service&Support; Contact; [email protected] +86-13002508187. Home; Production Process; Adjustable Wrench Manufacturing Process; Adjustable Wrench Manufacturing Process. 30 years+ experiences in hand tools feilds. Offer the turn-key project.

Learn MoreEastman - Socket Spanners & Hand Tools Manufacturers, Dealer

Our manufacturing process is constantly refined and updated, taking advantage of the latest technologies and improvements. The quality schemes in place are under continuous re-assessment, such as our dye penetration inspection, which remains the best available method for detecting cracks in base materials.

Learn MoreDouble Open Ended Jaw Spanners Manufacturers

Our manufacturing process undergoes stringent quality checks so as to maintain the standard. We also have the ability to custom make our range as specified by

Learn More

Leave A Reply