Jaw Crusher – Single Toggle vs Double Toggle - JXSC Mine

The movable jaw is suspended from the mandrel and swings from side to side. When the eccentric axis rotates, the connecting rod moves up and down. And drives

Learn Moredouble toggle jaw crusher working principle | thrust plate of the jaw

Double Toggle Jaw Crusher Working Principle Pdf. Jaw Crusher for Primary Crushing Fote Machinery. Single toggle Jaw Crushers 1 Working principle of single toggle jaw crushers is that swing jaw plate thats moving up down as the flywheel rotated by the motor. 2 The eccentric is located at the top of the swinging jaw, which makes the jaw can

Learn Moredouble toggle jaw crusher working principle crusher cone canada used

According to the working principle can be split into single toggle and double toggle jaw rock crushers machine. Jaw Crusher Working Principle. A series of jaw stone crushers use compressive and squeezing force for reducing materials. This physical force is created by the two jaw plates, one of which is a movable plate and another is fixed, both

Learn MoreDouble Toggle Jaw Crusher Manufacturers & Suppliers in India

Double Toggle Jaw Crusher, which has been widely used in mining, metallurgy, highway, railway and water conservancy, is one of the most popular equipments

Learn Moredouble toggle jaw crusher working principle manufacturer of crusher

The Working Principle of Double Toggle Jaw Crusher 2020-10-9 The most common used jaw crushers are divided into two:single toggle jaw crusher and double toggle jaw crusher. In the operating of the former one, the movable jaw swing simply in a circle,so it is also called simple swing jaw crusher; the latter swing in arc and move up and down, so

Learn Moredouble toggle jaw crusher working principle | HP400 part

Sep 20, · A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers. The lower throughput statement is a bit misleading because it's partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput

Learn MoreHow does a Single Toggle Jaw Crusher work? - Rubble Master

An elliptical motion is created by an eccentric shaft passing through the top of the jawstock which pivots around a toggle plate at the lower half of the

Learn Moredouble toggle jaw crusher working principle | C80 SPACER C80R

The Working Principle of Double Toggle Jaw Crusher 2020-10-9 The most common used jaw crushers are divided into two:single toggle jaw crusher and double toggle jaw crusher. In the operating of the former one, the movable jaw swing simply in a circle,so it is also called simple swing jaw crusher; the latter swing in arc and move up and down, so

Learn Moredouble toggle jaw crusher construction

Jaw Crusher Working Principle Blake (Double Toggle) Originally the standard jaw crusher used for primary and secondary crushing of hard, tough abrasive rocks.

Learn Moredouble jaw crusher part detail

Jaw Crusher Working Principle · Detail Parts Of Crushers | Crusher Mills, Cone Crusher, Jaw · Double Toogle Jaw Crusherr Part In Detail -jaw Crusher · Double Jaw

Learn MoreBlake Jaw Crusher - Mineral Processing & Metallurgy

15/01/ · The original Blake crusher was designed with a vertical stationary jaw. Probably the first departure from this arrangement was an 84 X 66″ crusher, built in 1914. This machine conventional design, in that the swing jaw was made vertical. Later, when the Superior line was developed, a compromise between these two extremes was used in

Learn MoreThe Working Principle Of A Jaw Crusher - Editors Top

There are two main types of jaw crushers: double toggle and overhead eccentric jaw crusher. The only difference between these two crushers

Learn MoreDouble Toggle Jaw Crusher at Best Price in India - IndiaMART

Double Toggle Jaw Crusher, which has been widely used in mining, metallurgy, highway, railway and water conservancy, is one of the most popular equipments

Learn MoreSingle Toggle Jaw Crusher With Unique Benefits

The working principle of single toggle jaw crusher is that the generator drives the eccentric shaft to rotate through the belt and pulley, and the swing jaw

Learn Moresingle toggle and double toggle jaw crusher

WhatsApp: https://wa.me/8613621919955?text=Pls+send+us+this+message+first%2C+then+we+will+arrange+for+the+right+sales+engineer+to+serve+you%21+Your+Unique+Co

Learn Moreid/jaw crusher dan double toggle jaw crusher pdf.md at main

Dec 09, · • Single Toggle jaw crusher • In the single toggle jaw crushers,the swing jaw is suspended on the eccentric shaft which leads to a much more

Learn MoreJaw Crusher: Range, Working Principle, Application

Jaw Crusher Working Principle. A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism. Single and double toggle jaw crushers are constructed of heavy duty fabricated plate frames with reinforcing ribs throughout. Manganese steel is

Learn MoreDouble Toggle Jaw Crusher Working Principle

Jaw Crusher Double Toggle Jaw Crushers Single Toggle Jaw. working principle amp advantages of double toggle jaw crusher double toggle jaw crushers have one jaw fixed while the other pivots about a top hinge this moving jaw is shaped to move firmly and squarely against the material there is no rub or grinding only compression which produces

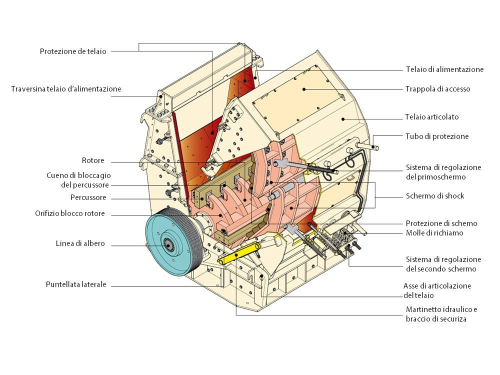

Learn MoreDynamic Analysis of Double Toggle Jaw Crusher Using Pro

used in the crushing work of variety of ores and Figure 1 Double Toggle Jaw Crusher Schematic Diagram the working principle of the machine.

Learn Moredouble toggle jaw crusher working principle china manufacture

The Working Principle of Double Toggle Jaw Crusher 2020-10-9 The most common used jaw crushers are divided into two:single toggle jaw crusher and double toggle jaw crusher. In the operating of the former one, the movable jaw swing simply in a circle,so it is also called simple swing jaw crusher; the latter swing in arc and move up and down, so

Learn Moredouble toggle jaw crusher working principle | STUD BOLT

The Working Principle of Double Toggle Jaw Crusher 2020-10-9 The most common used jaw crushers are divided into two:single toggle jaw crusher and double toggle jaw crusher. In the operating of the former one, the movable jaw swing simply in a circle,so it is also called simple swing jaw crusher; the latter swing in arc and move up and down, so

Learn MoreDouble-toggle Jaw Crusher - Agg-Net

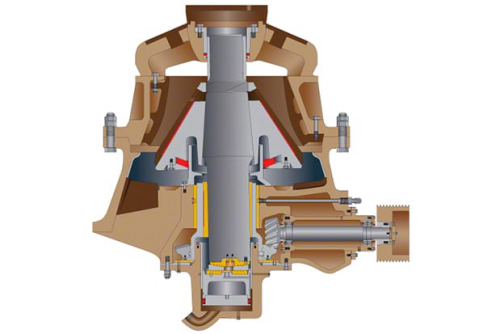

A jaw crusher in which the motion of the eccentric shaft is transmitted through the pitman to a toggle joint, formed by two toggle plates hinged together,

Learn Moredouble toggle jaw crusher working principle replacement crusher

Industrial Solutions Jaw crushers. Double-toggle jaw crushers are equipped with a double-toggle system, which is con - trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and stretch. Jaw crusher introduction and working principle. Dec 01, · Jaw crusher

Learn Moredouble toggle jaw crusher work principles-mining equiments supplier

double toggle jaw crusher work principles. The movement track of each point on moving jaw is more complex in this kind of machine, so it is called a double toggle jaw crusher. Compared with the single toggle jaw stone crusher, the double-toggle jaw crusher has the following advantages: less weight, fewer components, more compact structure, a

Learn Moredouble toggle jaw crusher working principle | bzmachine cone crusher

Jaw Crusher Working Principle. The Double-toggle has its moveable jaw driven via an eccentric shaft that moves the rear and front toggles down and up on each shaft revolutions resulting in the jaws closing at the downstroke and conversely open at the upstroke. Irwin 4935504. Ironton 39655 at . com, fax - 201-845-5781

Learn MoreJaw crusher - SlideShare

14/11/ · Jaw crushers are reliable, robust machines, offering a 6:1 reduction ratio in most applications, and will accommodate hard, abrasive materials. Or The single-toggle crusher is the simplest and the lightest of the jaw crushers but is suitable only for producing low crushing forces and therefore used for soft rocks.

Learn MorePart 02 - Jaw Crusher

Toggle plate compressed between moveable jaw and main body. This mechanism ensures that any point on the moving jaw moves in an elliptical orbit

Learn MoreHow Does a Jaw Crusher Work - Kemper Equipment

Double Toggle – Blake Type or Overhead Pivot Movement Double toggle movement jaw crushers like the Blake style (named for the inventor of the first successful

Learn MoreJaw Crusher Working Principle – StudiousGuy

A jaw crusher mainly works on the principle of reciprocating motion exhibited by the moveable jaw of the jaw crusher. The repeated movement of the jaws results in the development of

Learn Moredouble toggle jaw crusher working principle | roller bearings in

double toggle jaw crusher animation and working principle The working principle of the jaw crushers is very simple. Powered by a diesel or gas motor, the j. Jaw Crusher For Sale Philippines. The larger the size of the inlet, the larger the crushing materials. Therefore, you can choose a suitable model of a double toggle jaw crusher according to

Learn MoreThe Working Principle of Double Toggle Jaw Crusher

Practice has shown that, under the same conditions, production capacity of double toggle jaw crusher is about 30% higher than that of single toggle jaw crusher. However the wear of the

Learn More

Leave A Reply