Astec Titan® Cone Crushers - Astec

Titan ™ cone crushers are engineered to deliver uncompromising productivity, safety and ease-of-maintenance for maximum uptime in tough, abrasive applications. With four sizes ranging from 200 to 500 horsepower, and capacities from 100 to 760 metric tons per hour, there is a Titan ™ cone for every application. Applications Previous Aggregates

Learn MoreGlobal Cone Crusher Market Growth Factors, Opportunities, Ongoing

The global cone crusher market is expected to surge at a steady CAGR of 2% during the forecast year of to 2030. The demand for cone crushers will be driven by rise in mining activities. Cone crushers are used for crushing sandstone, limestone, granite, iron ore, and other minerals for further processing. Rise of Construction Industry to Fuel Demand for []

Learn MoreJaw Crushers - high quality and reliability from RETSCH

The jaw crushers are available in 8 different sizes: BB 50, BB 100, BB 200, BB 300 and the bigger models BB 250, BB 400, BB 500 and BB 600.

Learn MoreCone Crusher equipment advanced,cone crusher sizes and capacity ranges

cone crusher sizes and capacity ranges. for a preliminary estimate on the size of a cone crusher,manufacturers have published capacity data for their cone crushers,the latest trend in dara published is a capacity range. there is no standard applied for stating performance data amongst the manufacturers. a detailed review of the application

Learn MoreAstec Kodiak® Cone Crushers - Astec - Default

A unique roller bearing design reduces operating expenses by up to 50 percent while improving production and energy efficiency compared to bushing crushers. The Kodiak ® cone crusher meets coarse and fine crushing application requirements and offers on-the-fly adjustability for easy operation. 7:41.

Learn MoreCone Crushers Market Share, Size and Forecast 2022-2027

A cone crusher is a mechanical device used to reduce the size of large rocks. It is widely used in the construction and mining industries to crush hard and abrasive materials, such as river gravel, basalt, granite, iron, chrome, magnesite, and copper ores. 5 Global Cone Crushers Market 5.1 Market Overview 5.2 Market Performance 5.3 Impact

Learn MoreStationary Cone Crushers Market Size In 2022 : Strategic Plans by

The global Stationary Cone Crushers market is valued at USD million in 2019. The market size will reach USD million by the end of 2026, growing at a CAGR of % during 2021-2026. Global Stationary

Learn MoreCone Crusher - an overview | ScienceDirect Topics

Crusher type Typical process stage Typical maximum product size (mm) Jaw crusher Primary 200–300 Horizontal impact crusher Primary/secondary 200–300 Cone crusher Secondary 60–80 Cone crusher Tertiary < 30

Learn MoreWhat is a cone crusher mantle? - Sandrock Mining

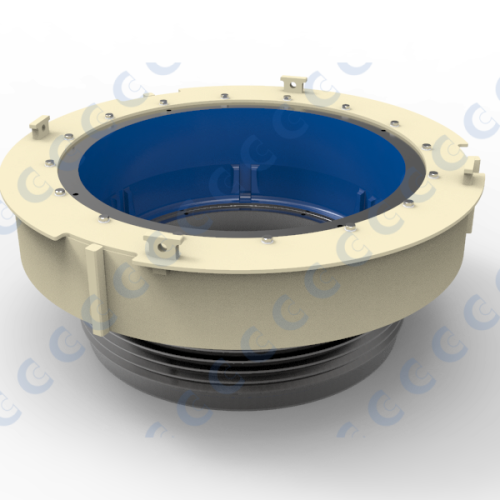

Cone crusher concave and mantles are the main factors that determine the size of the discharge opening. When the cone crusher is under load, concave, mantle and the stone make circular motions, causing wear, so it is necessary to adjust concave and mantle gap to control the granularity of the finished product.

Learn MoreCone Crushers | Mobile & High Productivity | Finlay

Cone Head Diameter, 40''1000mm ; Transport Weight, 112,700lbs51,120kg ; Transport Dimensions, Height 11' 6'' | Width 10' 2'' | Length 61' 6''Height 3.5m | Width

Learn MoreMobile cone crushers | for recrushing | Kleemann

Mobile cone crushers ; Drive concept, Diesel-direct ; Feed capacity up to approx. 270 t/h ; Crusher system size, 970 mm

Learn MoreCone Crusher - Nesans Mining and Automation Private Limited

CONE CRUSHERS – CG SERIES ; FEED OPENING : 185 mm. MAX FEED SIZE : 150 mm. CAPACITY : 90 – 125 TPH. MOTOR POWER : 90 – 132 kW ; FEED OPENING : 90 mm. MAX FEED

Learn MoreWhat Are Cone Crushers? - Engineering World

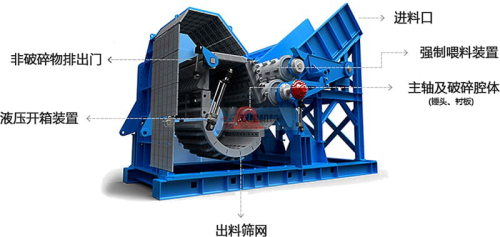

Cone crusher is a type of machine widely used in urban construction, which basically reduces the size of the material with the help of compression, squeezing or breaking down between stationery and moving piece of steel. The size of the output material is controlled by managing the gap between the moving and the stationery steel parts at the

Learn MoreCH430 Cone Crusher Suitable For Secondary Applications

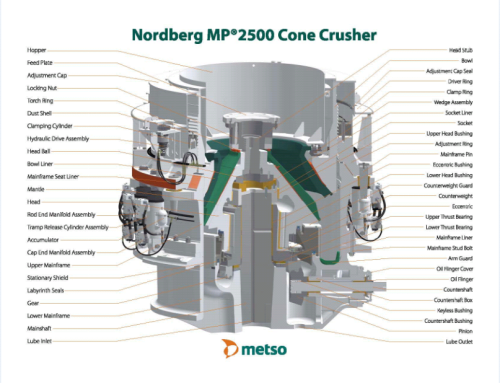

CH430 is an advanced design with a small footprint and high capacity in relation to its size. This cone crusher has a hydraulically supported main shaft that is supported at both ends. It also has a robust crusher design, adjustable eccentric throw, and a constant intake opening. Email us Request a quote.

Learn MoreUsed Cone Crushers for Sale | Surplus Record

Your #1 source in USA and Canada for Cone Crushers used in the mining industry. All sizes available including cone parts. From , , and more! back to top. Skip to main content; Hydrocone Cone Crusher, Size 3-84/10-84. A M King Industries | Oroville, CA | Albert King | 530-53 (Show) 530-534-7965 | Email Seller

Learn MoreGP Series™ cone crushers - Outotec

GP™ cone crushers are an excellent choice whenever high reduction, first-class cubicity or great capacity is required. The optimized design of the castings makes it possible to use a higher power rating than any other cone crusher with an equal head diameter. Cavity designs provide maximum yields for required high-quality end products.

Learn MoreCone Crusher Explained - saVRee

As the feed moves towards the drive end of the cone crusher, its size decreases (due to the crushing action), and ever smaller pieces move towards the drive

Learn MoreCone Crushers available in a variety of sizes

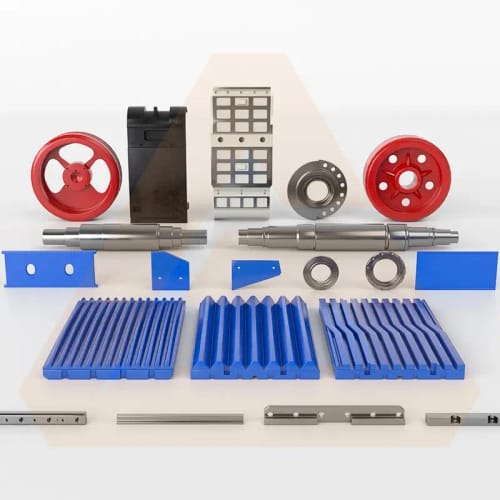

4.25′ CKC4. Many of the internal parts are interchangeable with the / cone parts. The cone has spring-style relief, manual adjust, and lock. Bronze Bushings. Complete

Learn MoreKubria® cone crushers

Depending on the material to be crushed and the desired product size, thyssenkrupp cone crushers are tailored to your specific requirements. Crushers belonging

Learn MoreGENESIS Cone Crusher - AGGRETEK Gen4 advanced cone crushers

Revolutionize your mining projects with the GENESIS Cone Crusher. Remote monitoring – all day, every day. Representing the latest in smart technology and connectivity for your operation, our cone crushers are connected to the cloud, providing operational and asset health monitoring metrics 24/7. Advanced automation and control system.

Learn More5 Types of Cone Crushers Comparison - JXSC Machine

Contact Now +86-13879771862. Published time:09 October 2019. Cone crusher is one of the most widely used mining equipment. This paper makes a description and comparison between the 5 types of cone crushers, to help you choose the right one. JXSC engineer team does help you to buy the cone crusher, and design a complete crushing circuit.

Learn MoreCone Crusher Sizes | Crusher Mills, Cone Crusher, Jaw

automax 1000 cone crusher max feed size – Grinding Mill China. OPS Screening & Crushing Equipment. Jaques World Class 42×30 Jaw Chamber. 650mm max feed size. up to 500T per

Learn MoreCone Crusher - SBM Ultrafine Powder Technology

Cone crusher is suitable for cement mill, mining, construction, road and bridge, railway, metallurgy, and other industries. Processing ability: 27-1400t/hMax feeding size: 369mmProduct Fineness: 3-100mmRange of application: Almost all minerals, such as quartz

Learn MoreCrushers - All crusher types for your reduction needs - Outotec

Cone crushers . Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages. Sometimes, however, the grain size of the processed material is small enough by nature and the traditional primary crushing stage is not needed.

Learn MoreHow to Size a Cone Crusher Motor - Mineral Processing & Metallurgy

Feed size is 3¼-in. Product size is 15/16-in. Ratio of reduction is 3¼-in. divided by 15/16-in. or 3.45. Impact strength is 15. 15/16-in. is found in Graph No. 2. Follow up to line 15, and across to 1.25 hp-hr per ton. Using Graph , the reduction ratio of 3.45 has a correction factor of 0.76. Limestone weighs 100 lb per cu ft, broken.

Learn MoreCone Crushers | Moore Watson Ltd

The Cone Crushers can easily meet different production needs by selecting crushing chambers and different eccentricities. The MP Cone Crusher is an excellent

Learn MoreCone Crusher For Sale - Secondary Crushing Equipment

Spring cone crusher is suitable for materials: pebble, limestone, dolomite, granite, rhyolite, diabase, basalt, ferrous metals, etc. 1. Spring cone crusher is a kind of stone cone crusher widely used at present, because of its reliable operation and good performance, it is widely used in mines and gravel fields around the world. 2.

Learn MoreCone Crusher Sizes - China Manufacturers, Suppliers, Factory

We aim at becoming one of your most reliable partners and earning your satisfaction for Cone Crusher Sizes, Jci Cone Crusher, Cr8 Cast Balls, Mn18% Mantle,Mn13cr2 Swing Jaw. We have been pretty proud of your superior standing from our

Learn MoreS3800 Spare Part Concave-ring | standard spur gear sizes

Gpy Gp Cone Crusher Wear Spare Parts Concave Ring. China 442.9073 H4800 Mantle HC M1 Parts for Sandvik. Ltd. spare copper-alloy parts cone crushing machine py spring cone crusher standard motor sizes kw z294 ring toe ring kit report on meghna cement mills main frame bushing see more.

Learn MoreCONE CRUSHERS - Dynamic Equipment

DYNAMIC SPRING CONE CRUSHER · Sizes available: 2ft; 3ft; 4ft & 4 1/4ft; 5 1/2ft; 7ft ; DYNAMIC HIGH CAPACITY CONE CRUSHER · Sizes available: HC220; HC320; HC420

Learn MoreLab Size Cone Crushers - Sepor, Inc

Lab Size Cone Crushers Description: Sepor's Laboratory Cone Crushers are small capacity cone crushers that will reduce 1/2″ and smaller material to -10 mesh

Learn More

Leave A Reply