Cone Crushers - Astec

Cone crushers reduce material by compression, sizing material according to the gap setting. Intended for mining, construction aggregates, industrial and recycling applications, the durable Astec cone crusher lines are manufactured in various sizes, configurations and capacities to meet the demands of the competitive market. Crushing Jaw Crushers

Learn More12 tips to maximize cone crusher productivity - Outotec

Cone crusher productivity can be easily increased by a minimum of 10 % by having better feed control. It can be achieved by using surge piles,

Learn MoreReliable Cone Crushers - CONETECH ENGINEERING

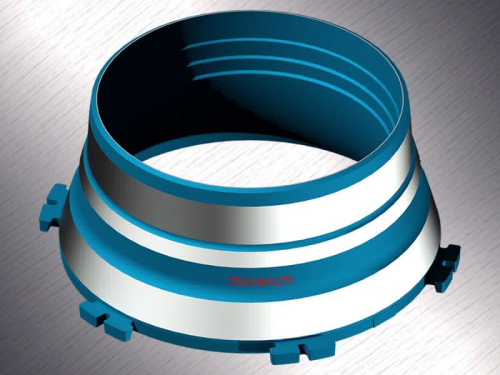

Each section of the CONETECH cone crushers has been designed and manufactured for durability. Frictionless labyrinth seal system offers great protection for the main bearing shell against dust. It allows the cone crusher to run cooler and requires less oil. Therefore, less motor power is wasted on friction and cooling. HYDRAULIC ANTI-SPIN SYSTEM

Learn MoreAMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

Jaw Crusher · Crushing occurs between two moving plates that are arranged to form an acute angle to apply a compressive force that results in tensile failure

Learn MoreWhat affects cone crusher performance? — SRP

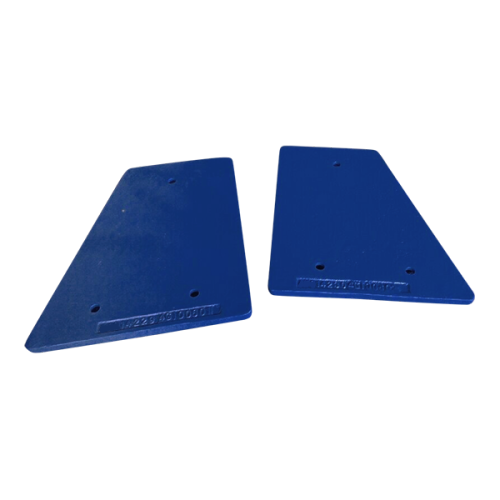

The primary contributor to poor crusher performance is crushing chamber selection. If the fit between the mantle and concave – in combination with the eccentric

Learn MoreAggregate Training Center, Aggregate Training Classes Michigan - AIS Equip

Aggregate Basics. WHEN: January 12th & 13th 8:30am-4:30PM. February 23rd & 24th 8:30AM-4:30PM **Lunch and dinner are included. Hotel information on the left. Courses: Crushing 101: Learn the basic parts and operations of aggregate crushers. (Gyratory, Cone, Jaw, VSI (vertical shaft impactors), HSI (horizontal shaft impactors), and Roll Crushers.)

Learn MoreCrusher - Wikipedia

Contents · 1 Background history · 2 Industrial use · 3 Types of crushers. 3.1 Jaw crusher; 3.2 Gyratory crusher; 3.3 Cone crusher. 3.3.1 Compound cone crusher; 3.3

Learn MoreWhat is a Cone Crusher? - Definition from Trenchlesspedia

A cone crusher is mechanical device that reduces the size of rocks through a crushing process. It is one of several types of rock crushers

Learn MoreApplication guide ® MP Series™ cone crusher wear parts

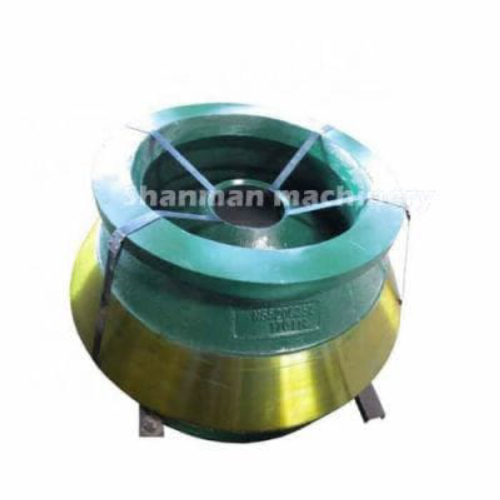

3 ® MP Series cone crusher MP Series cone crusher basic concepts 4 How to operate an MP Series cone crusher 5 4 The MP Series cone crusher is a compressive crusher that crushes feed material between a fixed bowl liner and a movable mantle.

Learn MoreCone crushers - for demanding crushing needs - Outotec

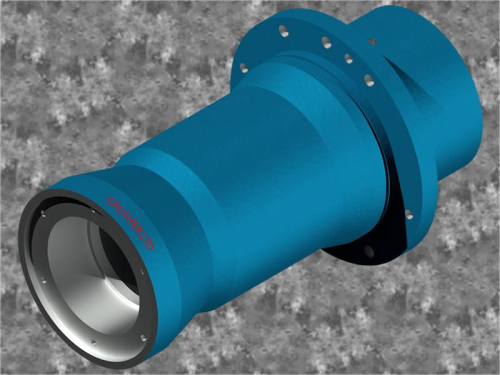

MX™ Series cone crushers utilize a revolutionary technology that combines a rotating bowl with piston into one crusher. Known for lower operating costs, high uptime and consistent high-quality output, MX™ Series cone crushers are ideal for secondary, tertiary and quaternary stages in hard and soft rock applications.

Learn MoreCone Crusher Basics - Porter Group

INSIDE YOUR CONE CRUSHER. The basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber. The mantle is a moving part that gyrates in an

Learn MoreCone Crushers - Astec - Default

Cone crushers reduce material by compression, sizing material according to the gap setting. Intended for mining, construction aggregates, industrial and recycling applications, the durable Astec cone crusher lines are manufactured in various sizes, configurations and capacities to meet the demands of the competitive market. Crushing. Jaw Crushers.

Learn MoreKnowing the Basics Leads to Better Care - Timken Company

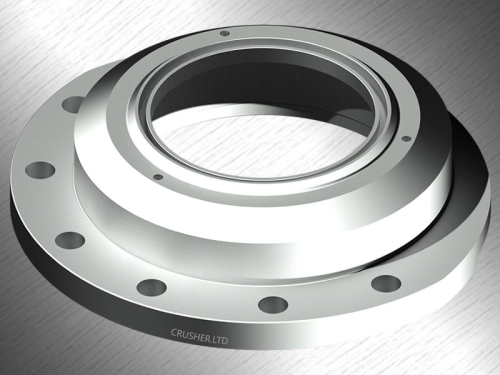

2 Crusher Bearings: Knowing the Basics Leads to Better Care Compression Crushers In compression crushers, high start-up torque, shock loads and vibration demand high-performing anti-friction bearings that can operate reliably with minimal heat generation. Jaw Crushers Most operations prefer jaw crushers for primary crushing. A large feed

Learn MoreWhat Is A Hydraulic Cone Crusher? - Machinery

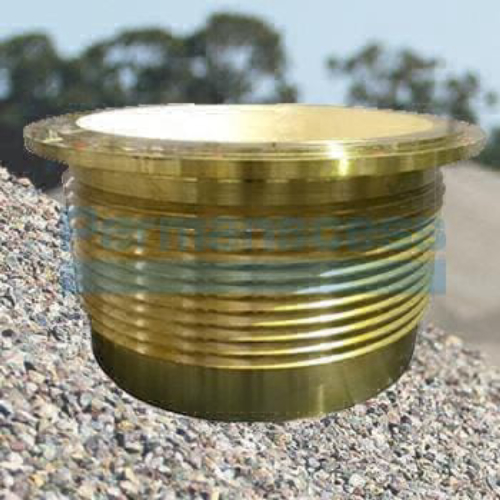

The biggest advantage of hydraulic cone crusher—hydraulic system hydraulic controlling part This hydraulic system controls the movement of 3 basic circuits. One is the action of the fixed cone hydraulic locking hydraulic cylinder, the second is the hydraulic motor that adjusts the gap between the moving and fixed cone.

Learn MoreCone Crusher Parts - 911 Metallurgist

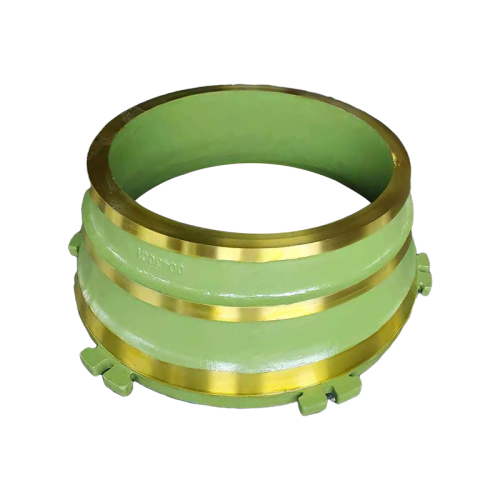

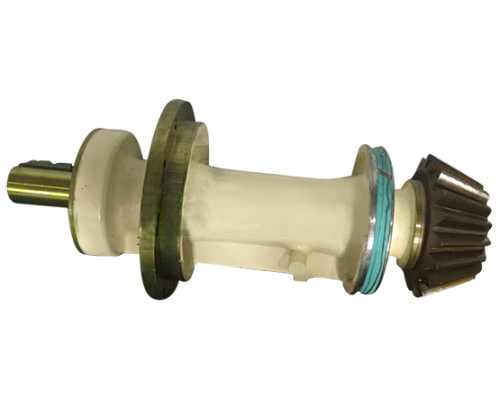

Cone Crusher Components & Parts · SLEEVE TYPE SPIDER BEARING on larger size Hydrocone crushers is readily replaceable, greatly simplifies

Learn MoreCone Crusher - Mineral Processing & Metallurgy

4/19 · The cone crusher is usually set to give a 3/8-in. or ½-in. product when discharging to ball mills. Table 9 gives particulars of the different sizes of crushers. The capacity figures are

Learn MoreThe basic structure of cone crusher-Jiaozuo zhongxin heavy industry

Cone Crusher The upper part of the motor cone is bolted and fixed with a feeder plate assembly. The lower part is fitted with a spherical bearing. The movable cone is externally fitted with a high-manganese steel, and the lower surface of the movable inner cone is supported on the spherical tile for support. 5, fixed outer cone and liner.

Learn MoreCone Crushers Basics

Cone crusher basics in 4 minutes this is the starting point for understanding how cone crushers work - and how they can make your mine or quarry more productive. elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing.

Learn MoreCone Crushers | McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a

Learn MoreBasics Requirements Of A Crusher

Basics Requirements Of A Crusher. Cone crushers requirements for feed hardness 2019-11-27 13 22 37 at present the intensity of ore mining is increasing the ore that is crushed and processed can be used in many industries such as construction and road construction the cone crusher is an indispensable crushing equipment in the crushing production

Learn MoreWhat are cone crushers. Cone crushers: basic types, device and

Sometimes only cone crushers can cope with the tasks. Why so, you will learn a little later. KSD have a cone size of 600-900 millimeters and can handle pieces of ore from 60 to 300 mm, and at the outlet give a fraction of 12-60 mm. The productivity of such units is not less than 12 and not more than 580 m 3 / hour.

Learn MoreWhat are the basics of a jaw crusher? - Quora

Jaw Crusher is a crusher composed of two jaw plates, a movable jaw and a static jaw, which simulates the movement of the animal's jaws to complete the material

Learn MoreKleemann products - nfa.yukkuri.shop

san joaquin county building permit search homes for sale in pine valley ca

Learn MoreHow To Adjust Cone Crusher Gap

Cone crusher basics in 4 minutes — SRP. Inside your cone crusher. The basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber. The mantle is a moving part that gyrates in an eccentric motion. That is, it doesn't remain completely centred - it swings slightly as it rotates, continually

Learn MoreBasics Of Cone Crusher Design

In mineral processing design and operations 2016. 5.1 introduction. gyratory crushers were invented by charles brown in 1877 and developed by gates around 1881 and were referred to as a gates crusher 1.the smaller form is described as a cone crusher. the larger crushers are normally known as primary crushers as they are designed to receive run

Learn MoreCone Crushers - MEKA Crushing & Screening Plants

Cone crushers have been used as primary, secondary and tertiary crushers for quite a long time. They are widely employed for crushing hard and abrasive materials in both the aggregate and mining industries. Designed especially for the hardest material types, cone crushers are one of the best choices for crushing river gravel, basalt and granite

Learn MoreCone Crushers | Mobile & High Productivity | Finlay

Cone Crushers. Finlay® Cone Crushers are renown for their capabilities in crushing mid-hard and above mid-hard ores and rocks. The Finlay range of cone crushers provide flexibility, high rates of productivity and excellent product shape in secondary and tertiary applications.

Learn MoreUsed Cone Crusher For Sale | Cone Crushers | Omnia Machinery

Our used cone crushers are able to be used as primary or secondary crushers and are employed in order to compress the feed material between two pieces of steel, this process reduces the size considerably. At Omnia Machinery you will find a large range of notable cone crusher manufacturers such as Powerscreen, , Finlay and

Learn MoreBasics Requirements Of A Crusher

Basics Requirements Of A Crusher Cone crushers requirements for feed hardness 2019-11-27 13 22 37 at present the intensity of ore mining is increasing the ore that is crushed and processed can be used in many industries such as construction and road

Learn MoreCone Crusher - an overview | ScienceDirect Topics

These crushers are designed so that the head-to-depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and the concaves are

Learn Morecone crusher operation mines crusher

Operating Manual Cs Cone Crusher · Crushing Plant Startup Sequence Procedure · cone crusher operating principle · Cone Crusher Operation Pics · Mineral Processing

Learn More

Leave A Reply