Designing a pad-eye: little items with big intricacies

05/04/ · Pad-eyes can also be without cheek plates, and they may also come with two cheek plates on either side. The base of the pad-eye is generally welded to the item to be lashed

Learn MorePadeye design and calculation

a pad eye consists of a main plate and occasional ring stiffeners. The main plate is conducted with a pair of cheek plates to stiffen the pinned connection and

Learn MorePadeye engineering tool development - TU Delft

The main plate is conducted with a pair of cheek plates to stiffen help in the design and strength check of a diversity of structures.

Learn MorePadeye Design Cheek | PDF | Mechanical Engineering | Civil

DESIGN OF PADEYE USING CHEEK PLATES Bottom of Spreader Beam Rev C1. Material Properties: Yield strength of plate Material performance factor Loads (using factors for Lift

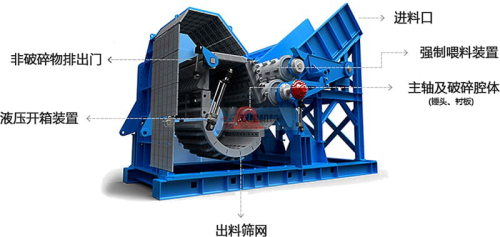

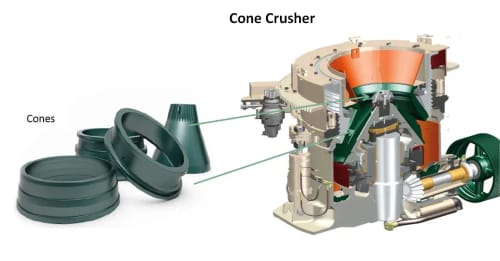

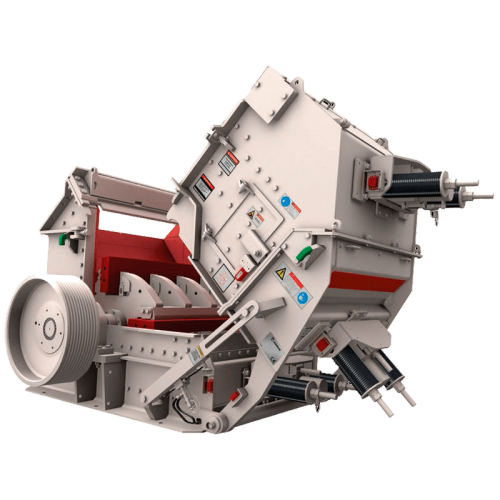

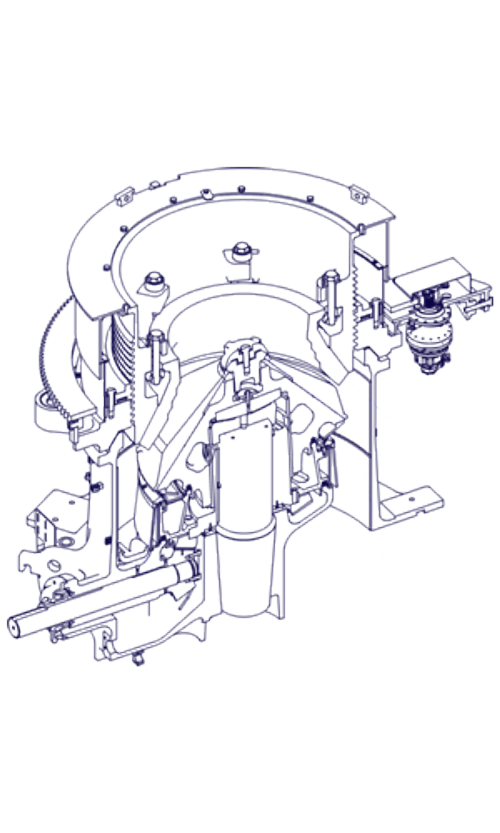

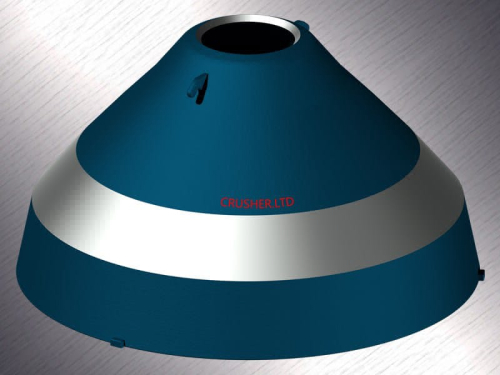

Learn Morejaw crusher cheek plate designs

The design of a lighter brittle crusher requires a more accurate billing of stresses and deflections in the sanding plates than is available in the conventional art The design of the oscillating cheek plate is made with CAD, ie the cheek plate was modeled with CATIAV5R16 in solid state

Learn MoreDesign of Padeye

designed as to permit free movement of the shackle and sling If fillet welded cheek plates are used to obtain the pad eye thickness required in 3.4.1

Learn MoreLifting Plate Design Assumptions - Eng-Tips Forums

Usually the cheek plates are included in order to centralise a large shackle jaw on what would otherwise be a thin main plate and reduce the possibility of twisting / out of plane loads. [ Post Deleted] CARunderscore (Structural) (OP) 29 Jan 18 22:59 Quote (RandomTaskkk)

Learn MorePadeye design and calculation

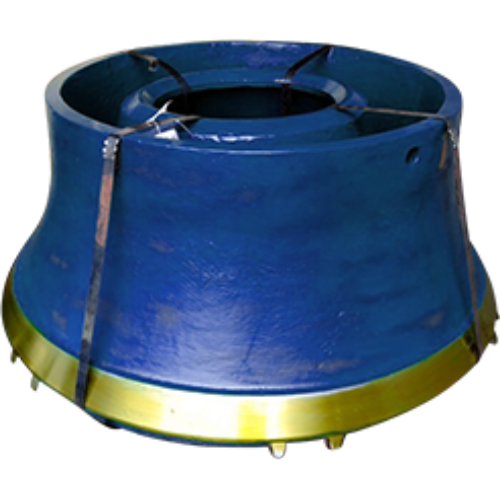

CHEEK PLATE For padeyes rated above 2000kg capacity cheek plates must be fitted to reduce the play in the shackle-padeye connection. These must be fitted as additional plates welded

Learn MorePDF C series jaw crushers Wear parts application guidePDF

piece jaw die design. A 1 piece jaw design is now also designed for large crushers (C110, C120, C125, C140, and C160). Upper cheek plate Lower cheek plate Movable jaw Fixed jaw 6 5 4 3 2 1 0. 10 Accessories Intermediate plate An intermediate plate can be used when feed capacity is low (empty cavity), feed size

Learn MoreUS5222886A - Cheek plate for a vane pump - Google Patents

It is an object of the present invention to design a cheek plate such that it can be manufactured at low cost. Specifically, fewer steps of manufacture are

Learn MoreStandard padeye CAD drawing ready for cutting (dwg, dxf, pdf

Standard pad eye design suitable for lifting and seafastening applications. (8) Plate thickness as per drawing and padeye weight as table below

Learn MoreNew & latest Cheek Plate products 2022 for sale online from

New Cheek Plate products manufacturing in China, with stylish and cool design emerge. Source new and latest Cheek Plate products in 2022 from credible China manufacturers, suppliers and factories. Contact most popular products of manufacturers, trading companies, wholesalers & exporter directly on

Learn MorePadEye Calculator | shackle compatibility & capacity | CalQlata

1) Enter design load including factors ( F) 2) Select a shackle size from the 'SWL' list 3) Enter cheek-plate and pin-hole clearances ( C & Cᴾ) 4) Enter a maximum allowable stress for the padeye plate ( σ) 5) And a few other dimensions (cheek-plate thickness, Young's modulus and weld joint factor)

Learn MoreCHEEK PLATE LOWER | altec dc1217 parts manual

A&S produces manganese wear liners and accessories for most crushing brands including , , , Cedarapids, , Plate 200421 Jaw Plate 200422 Jaw Plate 46590860 Jaw Plate 46591200 C110 JAW PLATES Cheek Plate Upper 901531 Cheek Plate Lower PDF pipe - tube - bar. - the perfect choice in stainless.

Learn MoreTHORDSEN CUSTOMS | Thordsen Customs

AR-15 Gen III Stock Kits. FRS-15 Gen III 5.56/.223 Bundles (AR-15) FRS-15 Gen III .308 Bundles (AR-10) FRS-15 Gen III AK-47 Bundles; FRS-15 GEN III SIG SAUER Bundles

Learn Morecrusher teeth of the cheek plates catalog details

英语网站资料. Contribute to /en development by creating an account on GitHub.

Learn MoreCLARK: CHEEK PLATE Cheek plate (reverse), with eagle design and the

Download CLARK: CHEEK PLATE Cheek plate (reverse), with eagle design and the motto 'The Spirit of Seventy-six,' on the butt of a rifle belonging to Am

Learn MoreCheek Plate Patterns | Library of Congress

Title Cheek Plate Patterns Contributor Names Harrell, Alfred (Photographer) Created / Published

Learn MoreCheek Plates 101 - What's Wrong With This Picture?

13/05/2022 · Apr 15, 2020. #1. Moving the head mount forward on this a full 6" after swapping out the 320 lbs 130 HP Subaru for a 170 lbs 160 HP Yamaha, permanently leaving elephant Soobie mother-in-law on ground permanently Just finished up the Visio cheek plates redesign this evening, thought to share with you the old problems that jump out that need

Learn MoreULTIMATE CAPACITY OF PAD EYES USED FOR LIFTING

main types of design geometries for pad eyes are described in NORSOK R-002 lifting stand - ard [1]. Type 1 is made of plate, with a uniform thickness, as shown in Fig, 2. Type 2 is made of cheek plates attached to the main plate by a fillet weld, as shown in Fig. 2, while type 3

Learn MoreCLARK: CHEEK PLATE Cheek plate (obverse), with angel design, on the

Download CLARK: CHEEK PLATE Cheek plate (obverse), with angel design, on the butt of a rifle belonging to American soldier and explorer William Clark

Learn MorePDF Optimum Analysis of Offshore Structures Lifting Padeyes Using Finite ...PDF

Padeye design and analysis plays an important roles during the lifting, load out and installation of heavy structures. This study addressed the different dynamic The effective thickness of the cheek plate can be increased to 100% with proper fabrication and welding sequence. Finite Element analysis is a good tool to have better

Learn MoreLifting Lug Design with example – What Is Piping

27/01/2022 · A Lifting lug is a plate with a hole in it. As the term specifies, lifting lugs are used for lifting. The hole is sized to fit a clevis pin. Using lifting lugs combined with the clevis pins, loads are transferred from one mechanical component to another. For mechanical static equipment (Fig. 1), these lifting lugs are used by cranes for

Learn MorePadEye Calculator (shackle compatibility & design capacity

Fig 2 shows the limiting stresses to be considered when designing a padeye. Bearing stress is distributed across the main plate and the cheek plates.

Learn MorePadeye Design Cheek.xls [j3nowq3opy4d]

DESIGN OF PADEYE USING CHEEK PLATES Bottom of Spreader Beam NOTES RELATING TO PREVIOUS SPREADSHEET PAGE Check requirements of CM-E-S-P-M00-PH.216 1. Edge distance Dr - Dh = 26.4 Dh = 126 Edge distance insufficient 2.Hole diameter Recommended hole diameter, Dh - Dp =

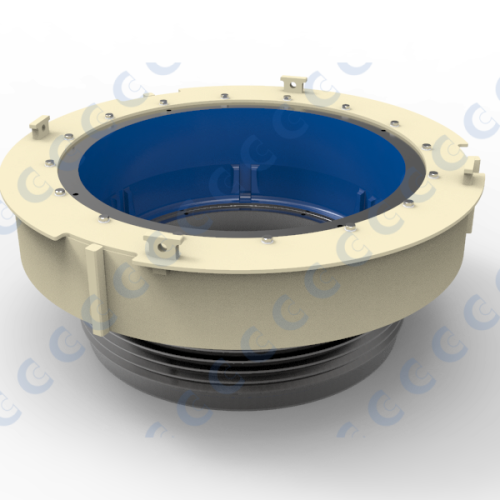

Learn MoreJaw and cheek plate lifting tools - Outotec

Crusher spare parts. Jaw and cheek plate lifting tools. Exclusively designed to lift Outotec manufactured wear parts for C jaw crushers.

Learn MoreCheek Plate - Sandrock Mining

We can provide customized design according to our clients’ requirement and also refine our products by our clients’ feedback. Available Models for Jaw Crusher Parts CJ Series CJ211,CJ409,CJ411,CJ412,CJ612,CJ613,CJ615,CJ8115

Learn MorePadEye Calculator | shackle compatibility & capacity

The padeye calculator is based upon the following calculation procedure: 1) Enter design load including factors (F) 2) Select a shackle size from the 'SWL' list 3) Enter cheek-plate and pin

Learn MorePadeye Design - Structural engineering general discussion - Eng-Tips

19/02/ · MVPs. zaxen (Structural) (OP) 15 Feb 12 23:58. I am designing a single padeye plate (no cheek plates) with a single shackle pin going through it. I am accouting for the two most

Learn MoreEffect of roll compactor sealing system designs

The studies were conducted on pharma- ceutical powders using laboratory roll compactors integrated with fixed side seals (cheek plates),

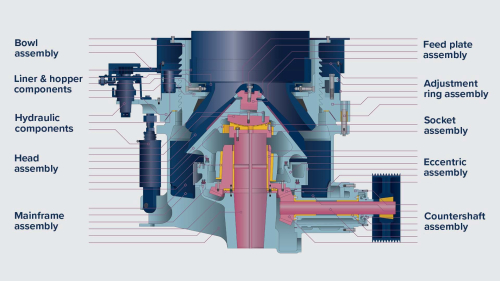

Learn MoreWhy skewing is not beneficial for your HPGR - Outotec

Traditional cheek plates vs. flanged roll design #3 - Skewing helps to even pressure across the full width of the roll. All machines with static cheek plates are designed to control skewing via the hydraulic system. Pressure is reduced on the skewing side of the roll with the smaller grinding gap (distance between the two rolls) in order to

Learn More

Leave A Reply