PDF) Design and Construction of Rock Crushing Machine

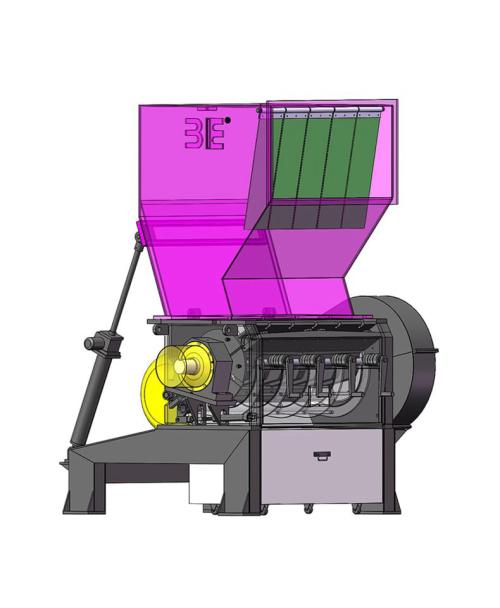

Calculation were carried out as per the required length,. shape, allowance and quantity needed to avoid waste of material. Jaw Crusher.

Learn MoreJaw Rock Crusher - BUILD Ep.5

Aug 20, 11K Dislike Share Description Donn DIY 847K subscribers Fabricating a jaw rock crusher from scratch. Making the toggle plate mount and fabricating a dedicated trailer using scrap

Learn MoreJaw Crusher Working Principle – StudiousGuy

Working Principle of a Jaw Crusher. A jaw crusher mainly works on the principle of reciprocating motion exhibited by the moveable jaw of the jaw crusher. The repeated movement of the jaws

Learn MorePDF Construction Working and Maintenance of Crushers for Crushing Bulk ...PDF

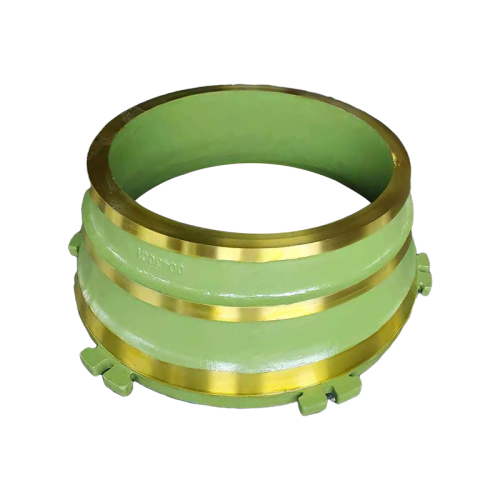

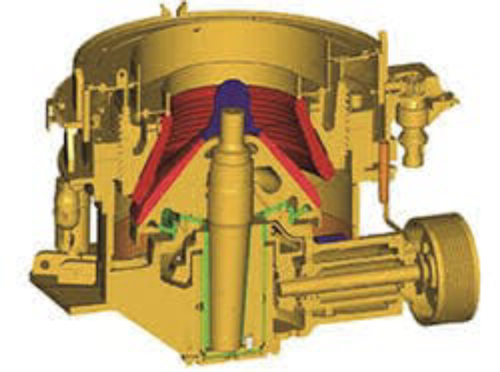

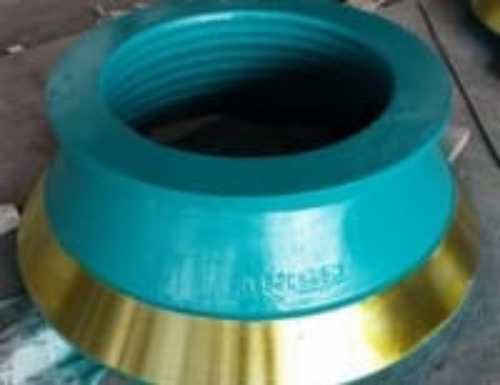

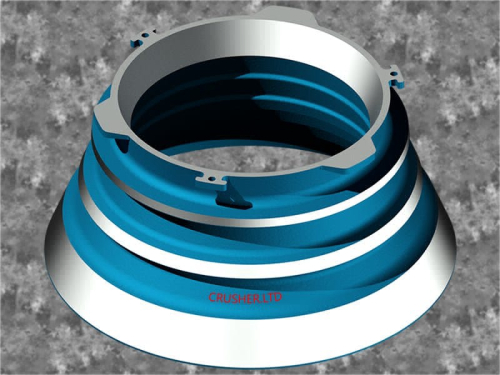

Construction detail and working of the crusher is as under. The main shaft of the crusher is journaled in the spider bearing and in the eccentric bearing assembly. The spider bearing fixes the position of the upper end of the main shaft. Eccentric bearing assembly with inner bushing can be replaced, or in some models turned, to adjust the stroke.

Learn MoreHow Does a Jaw Crusher Work | Jaw Crusher | Kemper Equipment

Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart. The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical product similar to impact crushers. Cone crushers have traditionally been used as secondary and sometimes tertiary crushing stations.

Learn MoreBR1000JG-1 Mobile Crusher

quarry industry where jaw crusher has traditionally been used, designed a peculiar 50- crushing of debris from construction work , the following.

Learn Moreconstruction of jaw crusher | sun hydraulics 740-224

Modular design is adopted to save time and installation cost, and minimize on-site construction work. Blake Jaw Crusher - Mineral Processing & Metallurgy. Jan 15, · In the history of crushers, both chronologically, and by virtue of its standing in the field of heavy-duty crushing, the Blake jaw crusher stands first in the list.

Learn MoreAIM: CRUSHING AND GRINDING MAHINERY: - DTE Assam

To study the construction, operation and engineering utilities of “Blake jaw Crusher” . into coarse crushers, intermediate crushers and fine grinders.

Learn MoreJaw Crusher | manufactor | thyssenkrupp Mining Technologies

All in all, thyssenkrupp’s jaw crushers are convincing due to their rugged and reliable design with high capacities, low wear and tear and high ease of maintenance. The advantages can be summarized as follows: Crushing of hard rock such as granite, basalt and ores. High capacity due to enhanced kinematics of the swing jaw.

Learn MoreHydra-Jaw® Crushers - Astec

Crushed Stone. Crushed stone is a versatile product that can be used in a wide range of applications from construction to road building and even agriculture. Processing this material may include reducing its size with a crusher, sizing the crushed material with a screen and conveying the material into different stockpiles.

Learn MoreJaw crusher: types, principle and applications - ResearchGate

Jaw Crusher can be used in mining, metallurgical industry, construction, road and railway building, chemistry etc. FEATURES OF JAW CRUSHER • Simple structure easy maintenance.

Learn Moreconstruction of jaw crusher

construction of jaw crusher America Corp.'s Mobile Jaw Crusher. Sep 28, · America Corp. announces the introduction of the BR580JG-1 Mobile Jaw Crusher. With a newly designed vibrating grizzly feeder and an all-hydraulic drive system the new crusher is suitable for highway construction, quarry and demolition and excavation

Learn MoreWhat is a Jaw Crusher? – MEKA Crushing Equipment

All jaw crushers feature two jaws: one of which is fixed while the other moves. The working principle of jaw crushers is based on the reciprocating movement

Learn MoreJaw Crusher Market Size, Share and Industry Growth by 2027

Jaw crusher finds its major application in construction & demolition, metallurgy, mining, water conservation, waste management. These equipment are powered

Learn MoreJaw Crusher | Crushing Plant | Hard Rock Mining Equipment | DOVE

DOVE JAW CRUSHER FEATURES: High tonnage capacity of up to 1000 Tons/ Hour, and low operating cost. Designed for toughest rock material, with compressive strength of up to 320 MPa. Supplied for Primary coarse crushing and secondary Fine crushing, within the rock reduction plant. Wide range of closed side setting adjustment.

Learn MoreJaw Crushers - Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

Learn MoreCharacteristics and Comparison of Four Types of Jaw Crushers

Mobile jaw crusher: High mobility determines that it is suitable for frequent conversion of crushing sites (like road construction, urban construction waste disposal, etc).Thus, its price is higher than other kinds of jaw crushers. Why choose Fote jaw crusher manufacturer? The various types of jaw crushers designed by Fote are widely used in many fields including heavy-duty mining, cement

Learn MoreConstruction Of Jaw Crusher With Their Parts In Pakistan

About CFTC PE jaw crusher Price in India: Sold to the region: India Type: Jaw Crusher(PE250*400,PE400*600,PE600*900,PE250*1000) Application: Construction, Mine. jaw crusher parts jaw plate Details. The jaw plate is the most important accessory in the jaw crusher and the most vulnerable part, so it often needs to be replaced. what is the price

Learn MoreBlake Jaw Crusher - Mineral Processing & Metallurgy

1/15 · The original Blake crusher was designed with a vertical stationary jaw. Probably the first departure from this arrangement was an 84 X 66″ crusher, built in 1914. This machine

Learn MoreConstruction Of Jaw Crusher Cone Crusher

Construction detail and working of the crusher is as under. The main shaft of the crusher is journaled in the spider bearing and in the eccentric bearing

Learn MoreJaw Crushers - Astec - Default

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

Learn MoreCrushing technology - kleemann

Jaw crushers operate according to the principle of pressure crushing. The crushed material is crushed in the wedge-shaped pit between the fixed crusher jaw and

Learn MoreScaled-up apparatus for removing petroleum and solid bitumen from rock

OSTI.GOV Journal Article: Scaled-up apparatus for removing petroleum and solid bitumen from rock and for separating them from each other. [Design, construction, and testing of jaw crusher, extraction plant, deasphaltization plant, absorption chromatograph, and rectification plant]

Learn MoreWaste #concrete crushing jaw crusher test video for waste construction

Jingying Machinery is the factory with over 30 years experience for the stone crusher line (stationary crushing line or mobile crushig line). Give me more de

Learn MoreJaw Crushers produced by Jaw Crusher Manufacturer | Korea Crusher

Jaw Crusher Manufacturer, Samyoung plant also manufactures single toggle jaw crusher with stationary and Mobile jaw crusher. As a Jaw Crusher Manufacturer of full set of crushing and screening equipment in Korea, based on years’ experiences and researches Samyoung plant has produced Jaw crusher (FSK Series) which is one kind of

Learn MoreFrame Construction Series Jaw Crusher

Jaw crushers supply the best way to crush hard stone. Dividing the style structural design simplify the installation specially in down hole operation. The speed

Learn MoreJaw Crusher Explained - saVRee

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top i.e. the opening), and each jaw will have a 54-inch width. If a

Learn More5 Common Questions about Jaw Crushers Answered | For Construction Pros

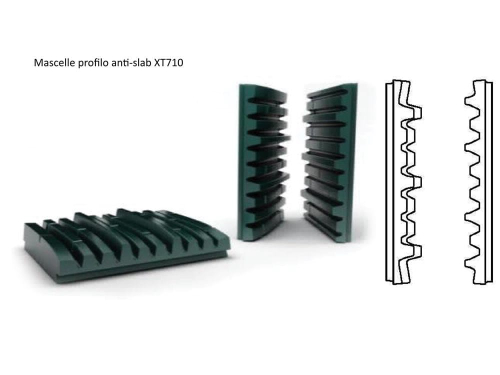

A fixed jaw, mounted in a V-shaped alignment, is the stationary breaking surface, while a movable, "swing" jaw exerts force on the feed material by pushing it against the stationary plate. The

Learn MoreConstruction Of A Jaw Crusher-HN Mining Machinery Manufacturer

Construction Jaw Crusher - karishmasteel.com. 20' X 30' Jaw Crusher. jaw crushers are the workhorse of the crushing industry for mining, construction, and demolition recycling. mt. baker mining and metals' jaw crushers are industrial grade, continuous duty machines. they take large pieces of rock, ore, concrete, or other materials, and crush

Learn Morejaw crusher construction - Crusher production line of large mining

A wide variety of construction equipment jaw crusher options are available to you, such as new. You can also choose from kyrgyzstan, turkey, and saudi arabia construction equipment jaw crusher, as well as from easy to operate, competitive price, and high productivity construction equipment jaw crusher, and whether construction equipment jaw crusher ::: 2021-7-23 · DOVE

Learn MoreGyratory Crusher - an overview | ScienceDirect Topics

A jaw crusher consists essentially of two crushing plates, inclined to each other forming a horizontal opening by their lower borders. Material is crushed between a fixed and a movable plate by reciprocating pressure until the crushed product becomes small enough to pass through the gap between the crushing plates.

Learn More

Leave A Reply