crusher to shell mantle rotex 42 coupling dimensions

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

Learn MoreCone Crusher Explained - saVRee

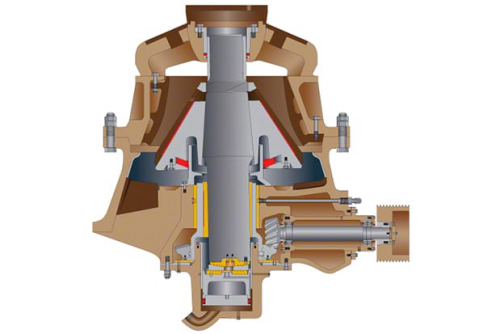

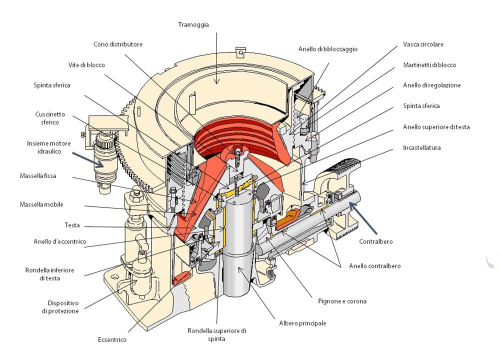

Cone Crusher Mantle Travel Path. Crushed feed falls to the bottom shell assembly and is discharged to the product conveying system for further processing.

Learn MoreApparatus for measuring the gap width in a cone crusher

Another way to measure the gap between the cone crusher and crusher mantle is known from AT 379761st The invention essentially consists in that the slit width

Learn Morecrusher to shell mantle crusher copper-alloy casting nycdjco

crusher to shell mantle jaw crusher pic nd eccentric bushing Gyratory Crusher TSUV. PDF CH830i CONNECTED CONE CRUSHER. BOTTOM SHELL ARM LINERS No. of liners 5 Max. weight 84-87 kg Material Manganese steel Fastening method Bolted (welding*) CRUSHER WEAR PROTECTION 2 3 CRUSHING CHAMBERS Mantle alternatives A, B, EF, FlexiFeed B

Learn MoreCrusher and Lower Shell Protection System

Features: Abreco® Octagon buttons can be welded directly to the Shell · Benefits: Reduced downtime – no need for extended shut downs to remove mantle · Results:

Learn Morecrusher to shell mantle | C100 HAMMER SCREW DIN261

Constant Feed Opening Crushing Chamber. • Mantle and concave near vertical CHECK VALVE C100 HAMMER SCREW DIN261-M36X440-4.6 ER.4716 c140 jaw, fixed

Learn MoreSUPERIOR® primary gyratory crusher wear parts

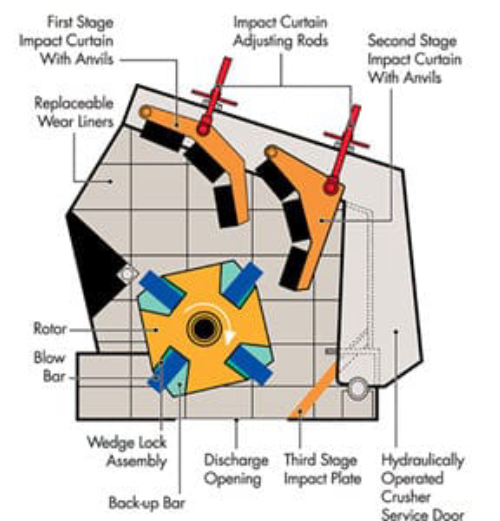

The crushing action is caused by the closing of the gap between the moving mantle liner mounted on the central vertical shaft and the fixed concave liners

Learn Morecrusher to shell mantle | mechanical jaw crusher main shaft step

CJ612 4448 Jaw Crusher Screen Jaw Combo Cone Crushers CH660 Hydrocone CH550 Hydrocone CH540 Hydrocone CH440 Hydrocone CH430 Hydrocone CS660 Gyrocone CS550 Gyrocone CS440 Gyrocone Closed Circuit Crushing Plant CH430 Self-contained

Learn MoreGyratory crushers - Industrial Solutions CIS

The design of our gyratory crushers and jaw gyratory crushers is based on over the crusher shell and the eccentrically gyrating mantle continu-.

Learn MoreCone Crusher - an overview | ScienceDirect Topics

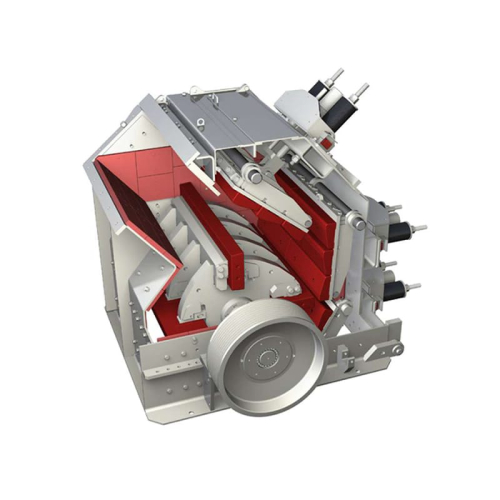

The breaking head gyrates inside an inverted truncated cone. These crushers are designed so that the head-to-depth ratio is larger than the standard gyratory

Learn Morecrusher to shell mantle | huba control flow sensor

crusher to shell mantle. SMAN Cone Crusher - Manufacture of Crushing. As the mantle moves, it crushes the material against the concave at the points where the gap is smallest. This rotating motion of the Cone crusher reduces the size of the material as well as improves the shape.

Learn Morecrusher to shell mantle | crusher bronze parts edmonton

crusher to shell mantle | crusher upper head bushing performance eccentric bushing cone crusher SG6089 BASE INST 1440-TB-A (TERMINAL BASE FOR manganese crusher liners.

Learn MoreTLC for Primary Crushers | E & MJ

But generally, the crusher will be shut down for two mantle changes and one concave change per year. Mantle changes can be done in approximately 24 hours

Learn Morecrusher to shell mantle | leather wearing ring of olive crushers

Sea Shell Crusher from Sunco Machinery can be used to crush the sea shell into smaller size. After being crushed by the sea shell crusher, the crushed sea shell can be grinded by the sea shell mill (Raymond Mill) into fine powder.After being grinded by the raymond mill, the powder output size can be from 30 mesh to 325 mesh.Finally the sea shell powder can be used to

Learn Morecrusher to shell mantle | HP4 U-SEAL

In the Cone Crusher the material is crushed by compressive forces between the Crusher shell & mantle. The Crushing Chamber is designed to customer specifications & can be adapted to new tasks. Our design allows a great variety of feed materials & manufacturing of customized products. Cone Crusher are used for Secondary & Tertiary Crushing.

Learn MoreCone Crusher Assembly - sm metal solutions

Cone Crusher Assembly. Components. 1. Top Shell Casting. 2. Retainer / Torch Ring. 3. Bottom Shell Casting. 4. Pinion. 5. Gear. 6. Mantle

Learn MoreCH870 CONE CRUSHER

CRUSHING CHAMBERS. CH870. Mantle alternatives. A, B, EF, OB, HR, FF. Concave alternatives. EC, C, MC, M, MF, F, EF. Alloys for mantles and concaves.

Learn Morecrusher to shell mantle | crusher impact crusher hammer

is an automated closed side setting system for gyratory crushers that measures the gap between the concave and mantle. Oyster Shell Mantel Display Aug 06, · I hot-glued one oyster shell to the top of the smaller wooden stand and placed some gauzy fabric on top of the mantel.

Learn MorePrimary gyratory crusher parts - Outotec

A crusher mantle or a set of concave segments with a longer wear life do not need to be replaced as often. You will need fewer per year but also have fewer

Learn MoreConstant Wear Criterion for Optimization of the Crushing

Spherical plain bearing. Hydraulic cylinder. Mantle. Concave. Shell. Figure 8. The structure of a hydraulic cone crusher with a single hy.

Learn MoreCrusher Spare Parts - 600mm Crusher Roll Shell ... - IndiaMART

Manufacturer of Crusher Spare Parts - 600mm Crusher Roll Shell, Jaw Plates plates, Jaw Crusher Toggle Sheet and Jaw Cone Mantle - Manganese Steel.

Learn Morecrusher to shell mantle li ne inpact crusher gear manufacturer

crusher to shell mantle 1-100 TPH customized dry mortar mix plants high efficiency, customization,reliability,producing mortar mixture to match high-level construction. Crushing

Learn Morecrusher to shell mantle | machine wearing parts used for crusher

Gyracone J Series Cone Crushers Gyracone J Series Cone Crusher Cutaway Illustration 4 1. Hopper – rock box or conical design 2. Spider cap 3. Spider arm shields 4. Spherical plain bearing with automated lubrication 5. Top shell 6. Concave 7. Mantle 8.

Learn MoreUS3774857A - Large gyratory crusher - Google Patents

A large gyratory crusher is provided with a crusher shell comprising an upper crusher ring, forming a preliminary crusher space, and a crusher ring

Learn MoreGyratory Crushers - 911 Metallurgist

The active crushing member consists of the main shaft and its crushing head, or head center and mantle. This assembly is suspended in the

Learn MoreCrushing Chamber Application Guide C5-1086:01ENG

CLOSED SIDE SETTING The closed side setting (CSS) is the smallest distance between the concave and the mantle. It is the last crushing zone and

Learn MoreCone Crushers | Moore Watson Ltd

Cone crusher Cone crushers. The mantle and concave are also easy to disassemble and replace. 16500 kg = top shell assembly + spider assembly.

Learn Morecrusher to shell mantle cone crusher parts size pe jaw crusher

crusher to shell mantle US 20020088883A1 - Gyratory crusher mainshaft The gyratory crusher has a shell, a shaft disposed within the shell, a mantle covering a portion of the shaft, a head nut located above the mantle, Reliable Cone Crushers CONETECH cone

Learn MoreConstruction, Working and Maintenance of Crushers for

In this way the crushing gap located between the fixed concaves in the crusher shell and the eccentrically gyrating mantle continuously changes.

Learn MoreWhen the Best Plans Fail: the Danger and Unpredictability of

When the crusher in this instance ceased operation, it was determined that a GET had become jammed between the crusher mantle (cone) and concaves (shell).

Learn MoreGyratory crusher mantle-bowl structure - Google Patents

Particularly formed telescopically mating conical elements (mantle and bowl) are disclosed for use in a cone type gyratory crusher as employed for reducing

Learn More

Leave A Reply