kubria® Cone Crusher | manufactor | thyssenkrupp Mining Technologies

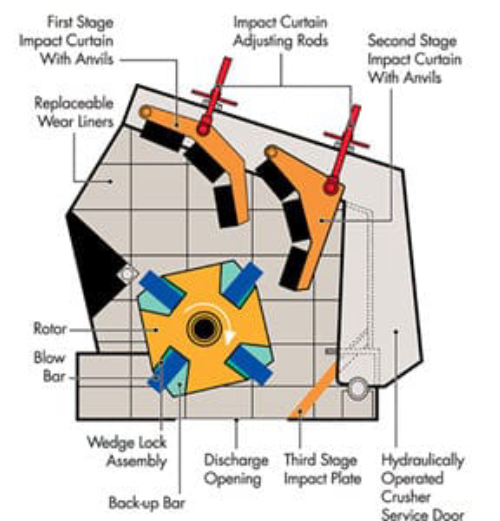

Cone crushers work on the principle of compression. The crusher squeezes the material until it breaks apart. By opening the crushing gap, the material slips downwards to be compressed again. In the production of concrete and aggregate products, the cone crushers achieve high cubicity and thus meet the required product standards.

Learn MoreCone Crushers | Rock Crushers | Aggregate Crusher - Lippmann-Milwaukee

Cone Crushers feature a unique combination of crusher speed, throw, and cavity design. This combination has proved revolutionary in providing higher capacity and superior product quality, and in providing a wider range of application suitability. From limestone to aconite, from ballast production to manufactured sand, and from small portable

Learn MoreGlobal Cone Crusher Market Growth Factors, Opportunities, Ongoing

The global cone crusher market is expected to surge at a steady CAGR of 2% during the forecast year of to 2030. The demand for cone crushers will be driven by rise in mining activities. Cone crushers are used for crushing sandstone, limestone, granite, iron ore, and other minerals for further processing. Rise of Construction Industry to Fuel Demand for []

Learn MoreCone Crushers For Sale

Cedar Rapids CR MVP380 Cone Crusher Extensive service and maintenancerecords available NEW Bowl liner NEW Gear box NEW 6 x 20 Bare Screen Triple Deck 2 cross Condition. Used. MLS Number. 11568046.

Learn MoreCone Crushers | Crushing Plants | DOVE

Cone Crushers are configured with Hydraulic Lifting-Arm, where in the case of power failure, it allows the operator for rapidly rotating and removing the top-shell in order to remove the stuffed material inside the crushing chamber. The hydraulic adjustment unit will also allow easily and rapidly to perform the required setting adjustments, and

Learn MoreCone Crushers - SolidsWiki

A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating spindle, which is covered by a wear resistant mantle, and the

Learn MoreCrushers Archives - International

C2C Compact Cone Crusher. MC200 Cone; Tracked; Compact footprint for high manouverability and ease of transport ; Twin pole over and under metal detector with variable sensitivity; C2C Compact Cone Crusher Details. J6 Jaw Crusher. Large 48"x34" Jaw opening to accommodate large feed sizes.

Learn MoreCone Crusher at Best Price in India

Spring Cone Crusher: Spring cone crusher consist of frame, transmission device, hollow eccentric shaft, bowl-shaped bearing, crushing cone, springs and

Learn MoreCone Crushers - Astec - Default

Cone crushers reduce material by compression, sizing material according to the gap setting. Intended for mining, construction aggregates, industrial and recycling applications, the durable

Learn MoreUsed Cone Crushers for Sale | Cleveland Brothers Equipment

If you're in the market for a mineral cone crusher or related construction equipment, browse our current inventory and contact our used equipment sales department at 1-866-956-8733 or our CB HYMAC division at 866-268-1714 for expert assistance finding the model that's right for you. Grid List.

Learn MoreReliable Cone Crushers - CONETECH ENGINEERING

CONETECH cone crushers are equipped with dynamic setting system, which allows to adjust the CSS during the operation and from remote locations. This system is powered by a hydraulic power unit that rotates the mantle on a thread and changes the distance between the bowl and the mantle. The system operates by a single press of a button and helps

Learn MorePopular Stone Cone Crusher for Sale (Multi-cylinder HP 400

HP multi-cylinder hydraulic cone crusher is suitable for crushing above medium hardness of various minerals androcks. Its high speed, high crushing capacity and unique patented design make the final products with a very high-quality cube type, and the characteristics of easy tomaintain ensure excellent high stability of the operation.It is the

Learn MoreRock Crusher Cone - 911 Metallurgist

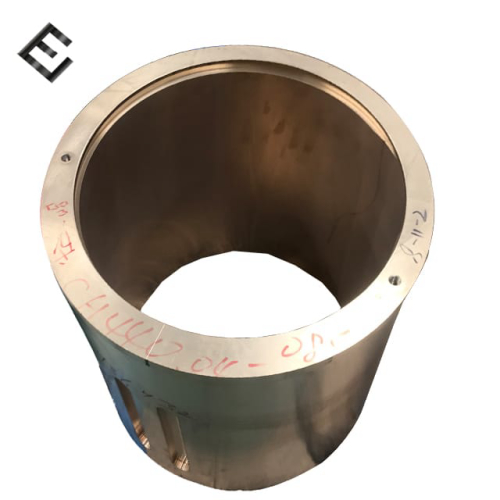

The cone crusher consists of a mainframe, transmission device, eccentric locking collar, bowl bearing, crushing cone, adjusting device, adjusting sleeve,

Learn MoreAstec Kodiak® Cone Crushers - Astec

The Kodiak ® cone crushers patented innovations provide the efficiency needed to hit financial goals and the worry-free operation demanded from rugged machinery. A unique roller bearing design reduces operating expenses by up to 50 percent while improving production and energy efficiency compared to bushing crushers.

Learn MoreWhat is a Cone Crusher?

12/20 · -12- :48:30. Cone crushers are a type of compression crusher used by aggregate, coal, concrete, crushing, fracking sand, and mining industries, which reduces

Learn MoreCone Crushers — Mining and Rock Technology

CS and CH cone crusher series. CS and CH cone crushers provide all the options you need to perform high performance work. With hydraulically adjusted CSS, the option of automation (included in the new generation of cone crushers CH540, CH550 and CS550), a choice of several different crushing chambers, and many other high-performance features, these

Learn MoreCone Crusher For Sale – Various Types Of Cone Crushers Available

A cone crusher is a type of crushing equipment using compression principles to crush hard and abrasive materials. It is widely used in metallurgy, construction, road construction, chemical, and silicate industries for crushing raw materials such as river pebble, granite, basalt, iron ore, limestone, quartzite, diabase, iron ore, gold ore, copper ore, etc.

Learn MoreHow to maximize cone crusher performance

A cone crusher uses compression to effectively crush abrasive material, as well as a wide variety of stone from medium to very hard

Learn MoreHydraulic Cone Crusher, Stone and Construction Waste Crushing

Hydraulic Cone Crusher. The cone crusher integrates mechanical, hydraulic, electrical, automatic and intelligent control, and adopts the principle of layer compression crushing, which is able to crush hard materials such as masonry and stone in construction and decoration waste to a small size, and the finished product is of high quality, with a cubic shape and high content of fine particles

Learn MoreWhat Is a Cone Crusher and What Can It Do for You?

A cone crusher is one of many different types of crushers, like impact crushers, jaw crushers, and hammermills, that is used to process and reduce material like aggregates and construction and demolition waste. The cone crusher distinguishes itself from these other crushers by how it operates in processing material.

Learn MoreCrushers - an overview | ScienceDirect Topics

Cone crushers are used for intermediate and fine crushing after primary crushing. The key factor for the performance of a cone type secondary crusher is the profile of the crushing chamber or cavity. Therefore, there is normally a range of standard cavities available for each crusher, to allow selection of the appropriate cavity for the feed

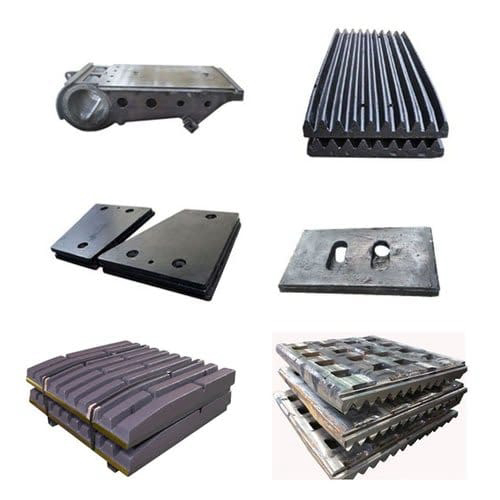

Learn MoreCone Crusher Wear Parts - Columbia Steel Casting Co., Inc

For better production and longer wear life, choose Columbia cone crusher liners. · Standard, heavy-duty, and custom wear parts for all popular cone crushers.

Learn MoreMarcy ® Lab Cone Crusher - Gilson Company

Marcy® Cone Crushers reduce medium to hard materials, such as aggregate and mineral ores. These crushers are powerful and tough enough for the continuous

Learn MoreCone Crushers | Moore Watson Ltd

Cone crusher capacity charts are developed for use as an application tool to properly utilize the MHP crusher's capabilities. The capacity figures shown apply to material weighing 100 pounds per cubic foot or 1600 kg per cubic meter. The crusher is one component of the circuit. As such, its performance is in part dependent on the proper

Learn MoreCone Crusher | 1000 Maxtrak | Powerscreen

At the heart of the Maxtrak is the Automax cone crusher with hydraulic setting, tramp release, and unblocking system. Its unique crushing action provides excellent capacity, high reduction, and good product cubicity for the production of high quality aggregate and sub-base materials. Find a Dealer. Specifications;

Learn MoreCone crushers - for demanding crushing needs - Outotec

MX™ Series cone crushers utilize a revolutionary technology that combines a rotating bowl with piston into one crusher. Known for lower operating costs, high uptime and consistent high-quality output, MX™ Series cone crushers are ideal for secondary, tertiary and quaternary stages in hard and soft rock applications.

Learn MoreSteel Cone Fire Pit - C29

Used crusher part. Each steel cone fire pit is unique due to wear during rock crushing. Extremely heavy duty and very heavy! Delivered by forklift or dump

Learn MoreCone Crushers | McLanahan

Features & Benefits. A Cone Crusher will deliver a 4:1 to 6:1 reduction ratio. As we set the closed side setting tighter to create a finer output, we also reduce the volume or throughput capacity

Learn MoreCone Crushers - Parker Plant

Global Cone Crushers. The GC series of cone crushers feature a highly rugged, more compact design than the standard cone. While generally operating at higher speeds, the GC cone features several eccentric throw and speed combinations to maximise performance and give greater reduction capability as well as higher application throughputs.

Learn MoreCone Crusher - an overview | ScienceDirect Topics

These crushers are designed so that the head-to-depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and the concaves

Learn MoreCone crusher basics in 4 minutes — SRP

This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information

Learn More

Leave A Reply