Double Roll Crusher Working Principle-HN Mining Machinery Manufacturer

Aug 11, The Working Principle of Roll Crusher. Double-roll crusher can be divided into high speed and low speed double-roll crusher according to the revolving speed of roller; According to the installation methods of roller, it can be divided into two kinds: a roller bearing is active, and the other bearings is fixed and two roller bearings are active

Learn MoreRoll crushers - SlideShare

The particles are drawn into the gap between the rolls by their rotating motion and DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller

Learn MoreThe Working Principle Of Double Roll Crusher, Mobile Crushing Station

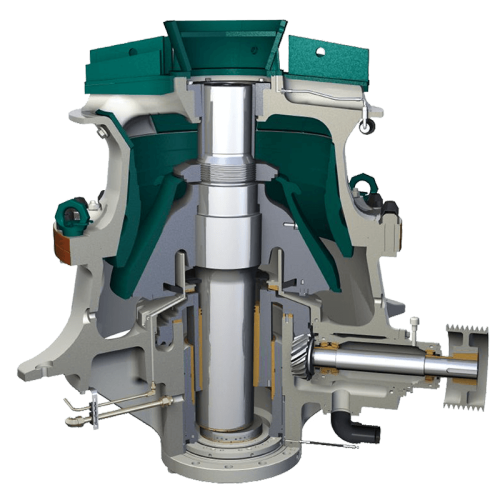

Working Principle Of Double Roll Crusher. brand Mobile crushing station is used and welcomed not only in China mobile crushers market but also world market. Hydraulic Cone Crusher. Hydraulic cone crusher, the latest generation of crusher in today's mining construction industry, can replace spring cone crusher and general hydraulic cone

Learn MoreDouble-roller Crusher DRC 200х125 (VIBROTECHNIK

09/04/ · See more: http://vibrotechnik.com/catalog/crushing-and-milling-equipment/double-roller-crusher/double-roller-crusher-drc-200-125/The Roller crusher with smoo

Learn MoreDouble Roll Crushers | McLanahan

How Double Roll Crushers Work. Operating Double Roll Crushers is quite simple. Whether it is a single or dual drive arrangement, the rolls are powered by electric motors and V-belt drive configurations, resulting in reliable and quiet operation. If it is a single drive arrangement, power is transferred from the driven roll to the non-driven

Learn MoreThe roller crusher working principle and matters Detailed

The working principle: The roll crusher will be broken material feeding the mouth fall between two rollers, extrusion, finished product material nature. When the weather is good or not broken, the roll crusher roller but by hydraulic cylinder or the role of the spring automatic, make the roll gap. increases, quality or broken down, so as to

Learn MoreRoll Crusher - an overview | ScienceDirect Topics

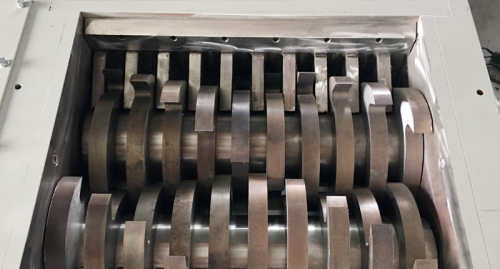

Double-roll crushers are able to crush more finely than single-roll crushers, because they are designed with teeth that mesh together rather than rotating past a smooth plate. They can reduce coal to as little as ¼ inch (0.6 cm) topsize, although they are more commonly operated close to

Learn Morewhat is the working principle of crusher

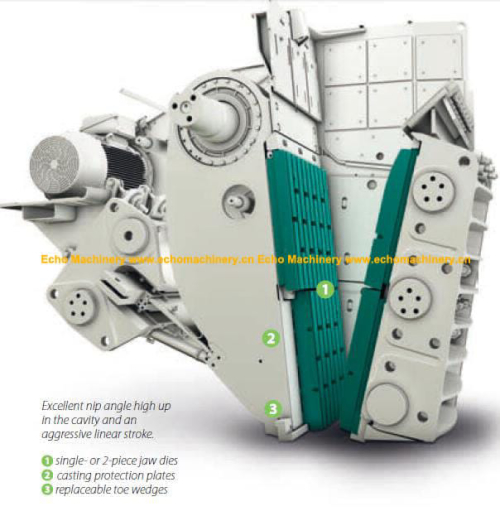

2. Crushers' Working Principle (1) Jaw crusher is the crushing equipment that uses two jaw plates to squeeze and bend materials to crush various hardness materials. The crushing mechanism is composed of fixed jaw and movable jaw. The material is crushed when the two jaws are close to each other, and the material smaller than the discharge gate

Learn MoreDouble Roll Crusher - Fote Machinery

Roller Crusher Working Principle The materials to be crushed fall from the feeding mouth to the space between the two rolls, after being squeezed and crushed,

Learn MoreRoll Crusher Working Principle

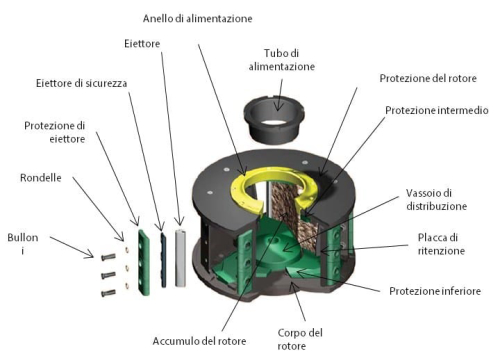

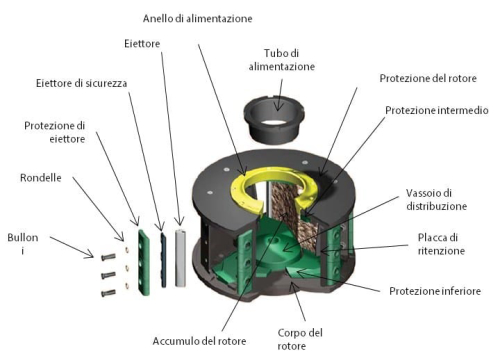

working principle of crushers Roll crushers - SlideShare. Apr 24, DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1.this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc. 2.the adjustment of the particle size: between the two

Learn MoreAugdouble Roll Crusher Working Principle

Working Process Of Double Toggle Crusher; 2017-11-8in 1858 eblake from the united states invented a new stone crusher and rock crusherhat is jaw crushert could crush solid rocks better as a result it could be used more widelyhe working principle of the double-toggle jaw crusher was a little more complicated than the roll crusher.

Learn MoreAdvantages and Disadvantages of Roll Crusher

The roller crusher, also known as double roller crusher , is suitable for medium and fine crushing. Its main component is toothed roll.

Learn MoreDouble Roll Crusher Principle

Working principle of double roll crusher a roll crusher crushes using compression with two rolls rotating about a shaft towards the gap between the rolls the gap between the rolls is set to the size of product desired with the realization that the largest feed particle can only be 4 times the gap dimension.

Learn MoreRoller Crusher | Single/Double Roll Crushers - JSXC Mine

Working principle. The material falls between the two rollers through the feeding opening to squeezing and crushing. Then the finished material falls naturally.

Learn MoreRoll Crushers - Top 2022 Models - 911Metallurgist

Both single and double-roll crushers have been extensively developed for crushing coal, coke, shale and similar soft and friable materials. Roll Crushing Action and Working Principle. The tip-velocity of the slugger teeth in the Fairmount-style crusher is from 400 to 450 ft/minute, or in the neighbourhood of 7 ft/second. The working faces

Learn MoreThe Working Principle Of Double Roll Crusher

Lab Double Roll Crusher . Working Principle. Lab Double-Roll Crusher is consist of the machine base, machine body, rollers, chain wheel, etc.The main drive roller is driven to run by the motor via roller belt, the main roller drive the driven roller to run synchronously by means of chain.Materials falling into the crushing chamber are crushed.This Lab Double-Roll Crusher has body and coupled

Learn MoreWhat's a Double-Roller Crusher?

The working principle of the roller crusher is that two sets of separately driven roller shafts crush the material by the squeezing force and

Learn MoreHow does a Double Roll Crusher works - Mineral Processing

28/12/ · How does a Double Roll Crusher works - Mineral ProcessingFor more mineral processing videos visit my Channel:http://www.youtube.com/hsrivastav /vi

Learn MoreSeries Stone Double Roller Crusher

The roller crusher can do secondary and fine crushing of materials with middle hardness or middle minus hardness, such as mineral, rocks, coke, coal, slag,

Learn MoreDouble Roller Crushers - SolidsWiki

Operation Principle. Double roll crusher is driven by the motor through the pulley or gear shaft opposite two rollers rotate, or were driven by two motors rotate two rollers. Double roll crusher

Learn MoreLab Double-roll Crusher

Working Principle 1.Roll crusher mainly consists of rollers, roller support bearings, pressed and regulation devices, drives, and etc. 2.Adjusting of output granularity: there is a wedge or gasket adjusting device between the two rollers. Wedge adjusting device:there is a adjusting bolt on the top of the Wedge device.

Learn Morethe working principle of double roll crusher

Working principle of Double roll crusher A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. The gap between the rolls is set to the size of product desired, with the realization that the largest feed particle can only be 4 times the gap dimension.

Learn MoreThe Working Principle of Double Roll Crusher

It is best suited for the intermediate and fine crushing in small and medium sized mine and chemical industry. The biggest compressive strength of crushed materials is 160Mpa. Roller crusher has advantages of simple structure, reliable work, low cost and less over-crush, it's suitable for crushing coal, coke, sinter and other medium hardness

Learn MoreThings You Should NEVER Do While Operating Double Roll

Smooth double roller crusher Usage and features and working principle. Today double roller crusher is utilized for crushing ore, coal, cement, glass, silicate

Learn Moredouble roll crusher lay out

Double Roll Crushers. Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals

Learn MoreHow Double Roller Crusher Works 3D Animation Video

The material enters into the space between the two rolls, suffered both extrusion and shear force.In the crowd rolling, cutting and grinding, it is crushed into the required size and then sent by

Learn MoreRoll Crushers - Top 2022 Models - 911 Metallurgist

Crushing rolls might, logically, include roll crushers of the sledging type, the name, by popular usage, is restricted to the double-roll machine (with

Learn MoreGundlach Multi Roll Crusher | PDF | Bearing (Mechanical ... - Scribd

Gundlach Multi-Roll. Crushers HANDLING A WORLD OF MATERIALS Gundlach Roll Crushers. Designed to precisely crush to product size and with maximum yield Our heavy-duty Gundlach Crushers roll crushers are designed with breakthrough 3-D crushing technology that includes intermeshing continuous tooth roll design and positive roll timing that delivers the industry’s

Learn MoreDual roll crushers, how they function - Mine Engineer

A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. The gap between the rolls is set to the size

Learn MoreHigh Quality Used Double Roll Crusher - The Nile Machinery

2-roll crusher is also called double roll crusher, double tooth roller crusher, etc. It can control the particle size of the output product and effectively

Learn More

Leave A Reply