Tips for Machining Gummy Materials - In The Loupe

Copper, titanium and stainless steel are difficult due to stringy chips. A combination of higher feed rates and lower speeds should also

Learn MoreWork Hardening and When It Should Scare You - In The Loupe - Machinist

10/30 · Incorrect speeds and feeds will cause more rub and less cutting, resulting in more heat generation passed to the workpiece. In these situations, machining can become next to impossible, and serious tool wear and eventual tool breakage are inevitable if the tool continues to be fed the same way. How To Avoid Work Hardening

Learn MoreFeeds and Speeds for Beryllium Copper - Industrial Forum

Hi all, We are starting to work with some beryllium copper in our shop, and are pretty inexperienced with machining of this material.

Learn MoreBrass, Bronze, Copper Drilling Speeds & Feeds - ChipBLASTER

ChipBLASTER, in Northwestern PA, creates high-pressure coolant system parts and recommends drilling speeds & feeds for bronze, brass & copper alloys Unlimited RPM 10,000 RPM *MAX 5,000 RPM *MAX 3,000 RPM *MAX Drill Size Feed Per Rev. SFM RPM

Learn MoreVarious Machining Copper Speeds And Feeds of High Quality

Total 24 Products for Machining Copper Speeds And Feeds) Machining Copper Speeds And Feeds - manufacturer, factory, supplier from China Machining of Cross Hole on Aluminum

Learn MoreMachining of Copper and Copper Alloys - ASM Digital Library

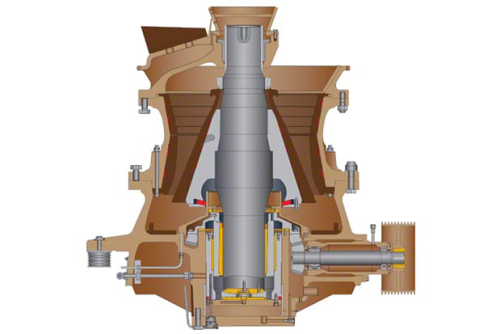

Because of the wide variation in machining characteristics among the various coppers and copper alloys, tool design, as well as speed and feed, must be varied

Learn MoreChina Machining Copper Speeds And Feeds Manufacturer, View Machining Copper Speeds And Feeds

Professional manufacture of Machining Copper Speeds And Feeds company, we can produce various kinds of Machining Copper Speeds And Feeds according to your request. Mr. Sun What can I do for you? +8613928436173 Twitter Home

Learn MoreRecommended machining parameters for copper and copper

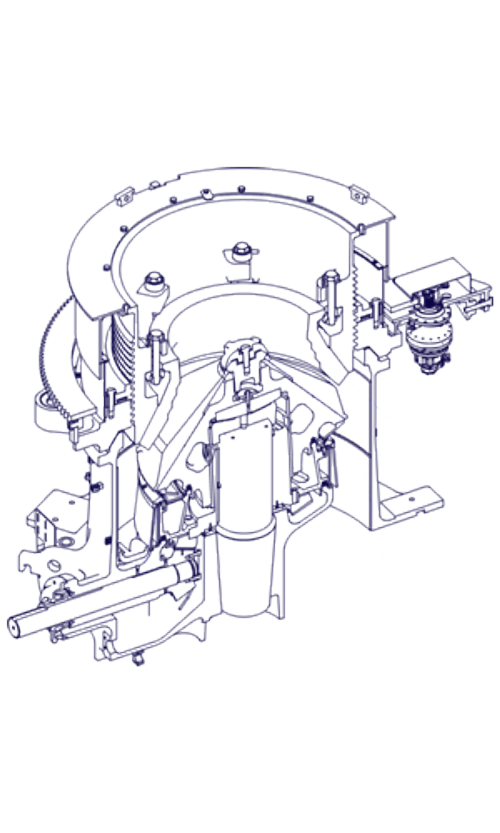

of the cutting and feed speed vectors. 2 Fundamental principles. Fig. 3: Face, flanks, cutting edges and corner of a turning tool (DIN 6581).

Learn MoreVarious Machining Copper Speeds And Feeds of High Quality, China

Total 24 Products for Machining Copper Speeds And Feeds) Machining Copper Speeds And Feeds - manufacturer, factory, supplier from China Machining of Cross Hole on Aluminum Plate High Precision CNC Machining Turning Aluminum High Precision CNC Machining Parts Custom CNC Machining Parts for 3D Printer Machining 316L Austenitic Stainless Steel Parts

Learn MoreFeeds and Speeds: The Definitive Guide (Updated for

Surface speed is measured in linear units per minute: feet per minute (SFM) for Imperial, and meters per minute in Metric. The faster the Surface Speed, the more heat that’s generated. So,

Learn MoreLearn Cnc Speeds & Feeds - with rpm & feedrate calculator

Feeds and speeds formula First is the formula to find the RPM, RPM = SFM* X 3.82 / diameter of the tool (* SFM = Surface Feet per Minute) You can also use the RPM calculator below Calculate RPM Next, the formula for the feedrate uses the RPM from the previous calculation, Feedrate = RPM X Feed per tooth X Number of teeth or

Learn MoreSpeeds and feeds - Wikipedia

When calculating for copper alloys, the machine rating is arrived at by assuming the 100 rating of 600 SFM. For example, phosphorus bronze (grades A-D) has a machinability rating of 20. This means that phosphor bronze runs at 20% the speed of 600 SFM or 120 SFM. Cutting feeds and speeds, and the spindle speeds that are derived from them,

Learn MoreVarious Copper Beryllium Machining Speeds And Feeds of High Quality

Total 24 Products for Copper Beryllium Machining Speeds And Feeds) Copper Beryllium Machining Speeds And Feeds - manufacturer, factory, supplier from China Machining of Cross Hole on Aluminum Plate High Precision CNC Machining Turning Aluminum High Precision CNC Machining Parts Custom CNC Machining Parts for 3D Printer

Learn MoreMilling Speed and Feed Calculator

Milling Speed and Feed Calculator. Determine the spindle speed (RPM) and feed rate (IPM) for a milling operation, as well as the cut time for a given cut length. Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill. Calculations use the desired tool diameter

Learn MoreGuide to Cutting Speeds and Feeds: Definition, Selection, Calculation

Speeds and feeds refer to two separate velocities - cutting speed and feed rate in machining, but they have a combined effect on the cutting process, determine the rate of material removal, surface finish, and power requirements.

Learn MorePDF) Optimization of Process Parameter Levels During

The milling parameters evaluated were spindle speed, feed and depth of cut. machining beryllium copper alloys. They are briefly.

Learn MoreTungsten-Copper- Machining - ESPI Metals

Turning & Boring: Roughing, approximately .030" deep and .020" per revolution feed. Finishing, .002" to.005" depth of cut and .001" to .002

Learn MoreCNC Milling Copper - Expert Guide - MellowPine

For milling pure copper, it is recommended to use a ⅛” (0.125”) 2-flute carbide end mill with 3000 - 5000 RPM and a maximum feed rate of 10

Learn MoreGeneral Machining Guidelines - Harvey Tool

Calculate the Speeds and Feeds of Carbide End Mills, Diamond End Mills, and Plastic Cutting Carbide End Mills with these General Machining Guidelines.

Learn MoreHow to Turn 101 Copper? | The Hobby-Machinist

Keep the feed rate between 5 and 8 thou/rev The speed should be 300 to 600 rpm. Pick which very gives you the finish your looking for, you can

Learn MoreFeeds and Speeds for Beryllium Copper

2003/3/23 · Hi all, We are starting to work with some beryllium copper in our shop, and are pretty inexperienced with machining of this material. If somebody with experience could suggest speeds and feeds for drilling and tapping, with both carbide and high speed drills, I would be very grateful. Thanks in a

Learn MoreMachining copper | Practical Machinist

You will need to experiment with your speeds and feeds. What kind of cuts do you need to make to get it to size and how thick is the material ?

Learn MoreSpeed & Feed Rates - Proto-Cutter

Copper Alloys (Copper Alloy Nos. as per the Copper Development Assn. Inc.) Material Condition* Cutting Speed, fpm: Drilling: Reaming: HSS: HSS: HSS: 314 Leaded Commercial Bronze 332 High Leaded Brass 340 Medium Leaded Brass 342 High Leaded Brass 353 High Leaded Brass 356 Extra High Leaded Brass 360 Free Cutting Brass 370 Free Cutting Muntz

Learn MorePDF SPEEDS AND FEEDS FOR CARBIDE ENDMILLS - Internal ToolPDF

carbide cutting tools speeds and feeds speeds and feeds for key cutters material plastic magnesium aluminum copper brass bronze cast iron steel titanium stainless nickel monel inconel waspaloy hastelloy type teflon nylon phenolic glass filled az,am,ez,ze,hk thru 6061 101-707 834-978 gray ductile malleable 1005-1029 1030-1055 1060-1095

Learn MoreCNC Speeds and Feeds | Easy Speeds And Feeds

304 SS INCH Carbide Drills Inch Speeds and Feeds 304 SS - Milling INCH Warning Always use the speeds and feeds recommended from your tool manufacturer. Easy Speeds And Feeds only serves as a starting point and educational site. 304 SS - HSS Drills INCH Warning Always use the speeds and feeds recommended from your tool manufacturer.

Learn MorePDF High Speed Machining of Brass: A New Benchmark in Productivity - copper.orgPDF

Maximum Speeds and Feeds Achieved. For single point turning, cutting speeds up to 4,000 surface feet per minute (SFPM), and feed rates up to 0.015 inches per revolution (IPR) were achieved for practical production periods (>4 hours) on all alloys utilizing a coated carbide insert. The chart below illustrates that the same amount of

Learn MoreThread Mill Feed and Speed Chart - Scientific Cutting Tools, Inc

Thread Mill Feed and Speed Chart. Thread Mill Locator. Material HB/Rc Speed SFM* Uncoated Speed SFM ALTiN+ Feed (Inches Per Tooth) Tool Diameter.032-.056.059-.090.100-.190.200-.350.370-.595.600+ Cast Iron: 160 HB: 100-200: Stay up-to-date with everything that Scientific Cutting Tools offers.

Learn MoreHigh Speed Machining of Brass: A New Benchmark in Productivity

Maximum Speeds and Feeds Achieved For single point turning, cutting speeds up to 4,000 surface feet per minute (SFPM), and feed rates up to 0.015 inches per revolution (IPR) were achieved for practical production periods (>4 hours) on all alloys utilizing a coated carbide insert. The chart below illustrates that the same amount of

Learn MoreMachining 110 Copper, my new favorite alloy!

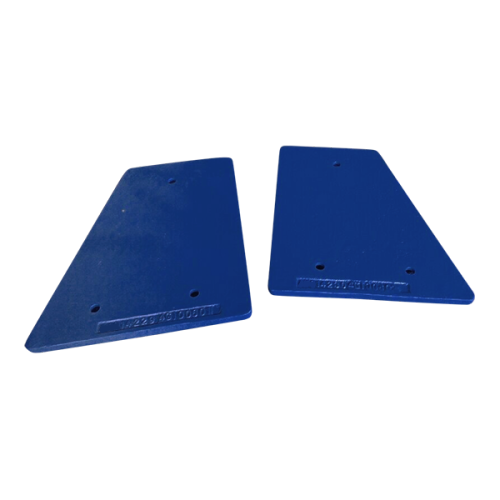

In this video I machine a custom set of vise jaws from 110 copper. In this video I machine a custom set of vise jaws from 110 copper. Fusion 360 CAM, feeds and speed included in the video

Learn MoreCNC Machining Copper: Understand the Pros, Cons

10/14 · Feed rate describes the rate at which the CNC cutting tool is fed (or advanced) against the workpiece. We recommend low to moderate feed rates for CNC machining copper

Learn MoreMachining nickel alloys

Feed rate and cutting depth should be set so that in following passes cutting is done below the previously work hardened layer. For example, in turning, a depth of cut at least 0.015 inch (0.38mm) is recommended if a following operation is planned, and the feed rate should be 0.005 inches (0.13mm) or larger.

Learn More

Leave A Reply