nip angle in jaw crusher

Up to10%cash back Jaw Crushers: Calculation Methods and Operation Principles. A Review [in Russ. Toggle navigation. Home; About Us; Products; Cases; Solutions; nip angle in jaw crusher 2020-09-18T20:09:45+00:00 Who we are > Products > Cases > Solutions > Contact Us > Solutions. Copper ore beneficiation plant;

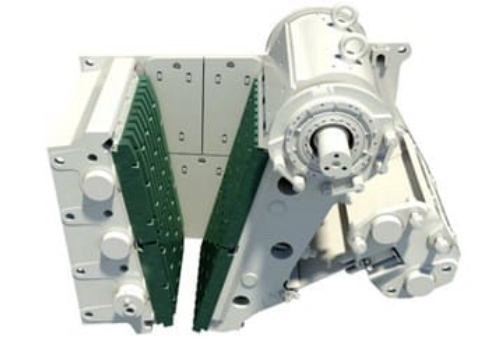

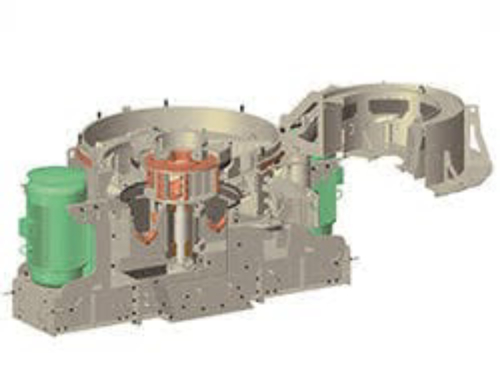

Learn MoreEngineered for the toughest feed materials ® C

The correct nip angle between the movable and fixed jaw dies ensures good bite and material flow down, even with slippery feed material. It also reduces we the jaw dies, reducing operating costs. With a good grip, the jaw crusher can crush rocks efficiently through the entirety of the cavity, and the nip angle can be further improved with

Learn MoreLiberty Jaw Crusher - Promac Processing Machinery

Superior engineers and manufactures more than a dozen compression-style jaw crushers, useful in primary crushing applications like quarried stone,

Learn MoreNip Angle Of Roller Mills - Gordon van Veelen

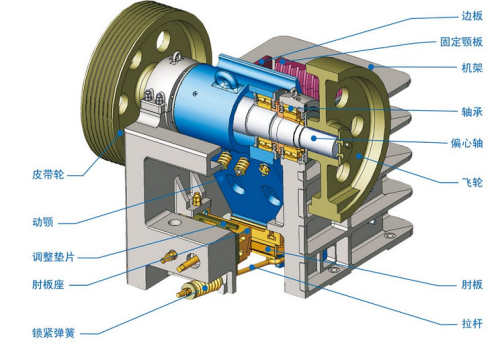

The nip angle describes the angle the stationary jaw plate and the pitman make with each other. The exact value of this angle isn't quoted or even determinable due to curvature in the jaws themselves but what is important is how wide vs. narrow it is. Wide nip angles can tend to expel material as the jaw closes as a large ball might

Learn MoreEffect A Nip Angle In A Gyratory Crusher

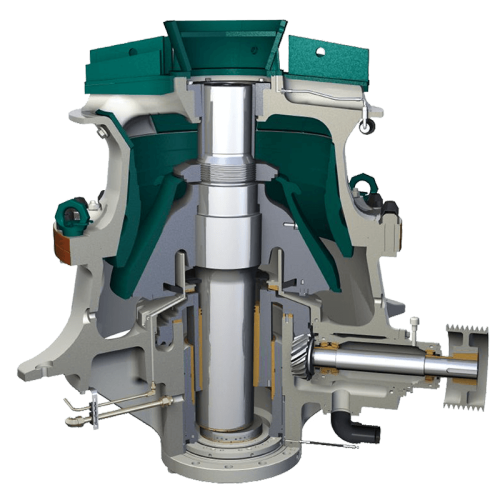

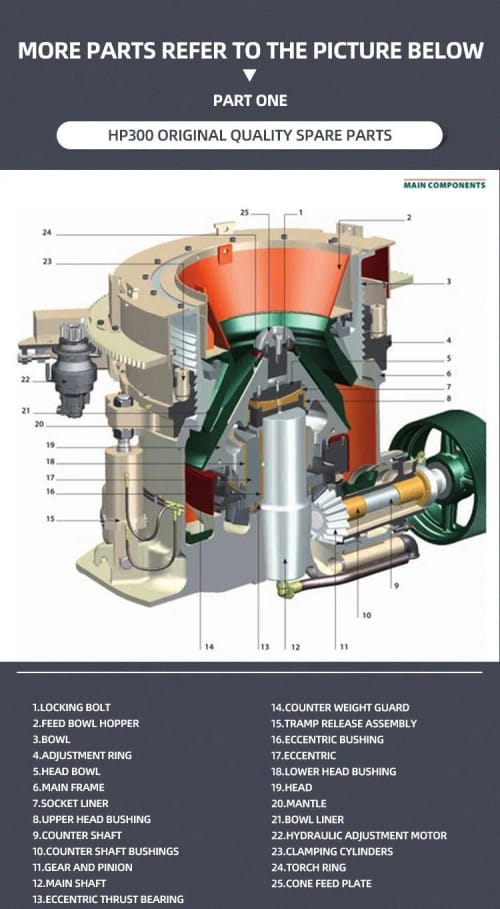

Effect A Nip Angle In A Gyratory Crusher. Prompt : Caesar is a famous mining equipment manufacturer well-known both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc. maximum nip angle on gyratory crusher model can accept. (B) Nip angle: .

Learn MoreTrio® CT4254 Series Primary Jaw Crusher - The Weir Group

Trio® CT series jaw crushers combine a robust design with a steep nip angle and an optimised toggle. This results in a crusher which offers a more

Learn MorePDF JAW CRUSHER SERIES - Mining and Rock TechnologyPDF

The nip angle is the angle between the fixed and moving jaw plates. Our CJ crushers have an optimum nip angle in the 16-23 degree range. Product picture to be placed here.

Learn MoreCalculating the nip angle of the chamber of jaw and ... - Springer

The nip angle for jaw, cone, and roll crushers is calculated according to the method simple jaw crusher with horizontal movement of the moving jaw.

Learn Moreangle of nip in roll crusher

Angle Of Nip For Jaw And Roll Crusher. We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related you are interested in our products

Learn MoreBasics Of Jaw Crushers - IMS Engineering

The smaller than average nip angle results in effective nipping and crushing of materials in the presence of moisture. Gap setting adjustment

Learn Morenip angle and crusher boiling in action | Mining & Quarry Plant

May 02, · The nip angle of the crusher jaw plates will determine the effectiveness of the machine. Influencing factor of crushing process – crusher for sale Large discharge opening will have large productivity but the reduction ratio will be reduced and the crushing action will also be The nip angle of Jaw Crusher,

Learn MoreNews - Jaw Crusher Intermediate Plate

1. To improve the nip angle (by decreasing the nip angle) when crushing slippery or round material (material that is difficult to bite). 2. To increase the length of the crushing zone (and thus increase the life of the jaw dies) when the feed material is consistently smaller than the

Learn Moreoptimum angle for toggle plate of jaw crusher | crusher spare

DOUBLE TOGGLE • ST has a larger angle of nip, the larger the nip angle the harder to grip the material.. JAW CRUSHER - HTM Maschinen - Weight of jaw crusher - Plate height fixed jaw - Plate height movable. Jaw Crusher - McNally .APPLICATION MSEL Double Toggle Jaw Crusher is a versatile type of Crusher. R J-1170 JAW CRUSHER - Excavators

Learn MoreJaggernaut Jaw Crushers - Adet

High Crushing Force. The nip angle and crushing stroke on Juggernaut jaw crushers are optimized to deliver excellent crushing action. An optimized nip angle will ensure the jaw plates grip the material and transmit the force effectively and the crushing stroke is designed to have maximum transmission of force in the crusher cavity

Learn MoreNip Angle In Single Toggle Jaw Crusher-HN Mining Machinery

The jaw, included-subtended two crushing face widest nip angle, is in the range of 26 degrees. Past 30 degrees most gyratory, cone and jaw crushers become inefficient at holding rounder

Learn MoreA REVIEW - African Journals Online

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER: A Figure 3: Angle of nip in a jaw crusher. 2.3 Crusher Jaw Plates.

Learn Moreangle of nip gyratory crusher

Maximum Nip Angle On Gyratory Crusher Gyratory Crushers Jaw Crushers Impact Crushers Angle Of Nip Varies For Large Crusher Between 21 To 24 For Curved Surfaces The Nip Varies From 27 To 30 Therefore If A 3 Mm Crusher Product Is Required Maximum Feed Size To The Secondary Crusher Would Be 240 Mm Thus The More Details

Learn MoreNip In Jaw Crusher

Nip Angle In A Jaw Crusher Angle Of Nip Of Jaw Crusher C116™ jaw crusher shares many of the same features as other jaw crusher models in the C Series™. Crusher

Learn MoreHow to improve jaw crusher performance and productivity

A Rock of low crushability requires a closer nip angle to keep the capacity as designed. A highly abrasive rock requires thicker and heavier jaw

Learn MoreJAW CRUSHER SERIES

Our jaw crushers are of the single-toggle type and feature a deep, symmetrical crushing chamber, a large feed opening for its size, and an ideal nip angle.

Learn Morenip angle in jaw crusher

Crusher Close Side Settings Mineral Processing . 17/01/ Nip angle The nip angle is the angle between the fixed and movable jaw dies Too large a nip angle reduces the capacity and increases the wear as the feed material grinds and gouges the jaw dies in an upwards direction during the compressive stroke nip angle of jaw crusher Mine Equipments,The jaw crusher is primarily an compression

Learn MoreCalculating the nip angle of the chamber of jaw and cone

Jaw Crushers: Calculation Methods and Operation Principles. A Review [in Russian], TsNIITÉstroimash, Moscow (1972). Google Scholar V. D. Rudnev and A. D. Rudnev, Method for

Learn MoreJaw Crushers - Groundworx Co

Minyu Jaw Crushers are widely recognized as one of the most successful jaws on the market today. Longer jaw dies and reduced nip angle easily produce more

Learn MoreIJC Series Jaw – Indus Crusher

Single toggle jaw crushers are designed to impart on a rock particle placed between a fixed and moving jaw plate. The moving jaw plate applies the force of impact on particles held against the fix jaw plate. Both the jaw plates are bolted on to heavy block. The moving jaw plate is pivoted at the top end and connected to an eccentric shaft.

Learn MoreHow does a Single Toggle Jaw Crusher work? - Rubble Master

The two jaw plates are positioned in a V-shape so that the space narrows from top to bottom. The angle within the V is known as the nip angle. An elliptical

Learn MorePDF Engineered for the toughest feed materials ® C Series™ jaw crushersPDF

Optimal nip angle ensures excellent bite in the cavity The correct nip angle between the movable and fixed jaw dies ensures good bite and material flow down, even with slippery feed material. It also reduces we the jaw dies, reducing operating costs.

Learn MoreTrio CT3042 Series - Weir Group

Trio® CT series jaw crushers combine a robust design with a steep nip angle and an optimised toggle. This results in a crusher which offers a more aggressive bite and reliable operation, with life-cycle improvements of its mechanical and hydraulic parts. These jaw crushers incorporate steeply designed toggle seats which enable efficient

Learn Morestandard crusher parts | nip angle in jaw crusher

7 ft (2 m) Standard Heavy Duty Cone Crusher Manufacturer: - Secondary crusher - Well maintained from closed mine - Weight: 149,000 lbs - Feed size: 10 - 18 inches (253 - 460 mm) - Production: 380 - 1360 metric tons/hour (418 to 1500 standard tons/hour) - Closed side set

Learn MoreJaw Crusher Nip Anglepdf In South Africa

Nip Angle On Jaw Crushers angle of nip in roll crusher. angle of nip in double roll crusher angle of nip in roll crusher or jaw crusher. Get Price. The Finlay 684 3-Deck Screener is a compact easily transportable machine that offers operators rapid set up and tear down times. The screenbox features three large 4.3m x 1.7m (14' x 5' 7

Learn MoreSimulation Analysis of Cavity Shape of Compound Pendulum

The compound pendulum jaw crusher is a kind of common crushing equipment which can the nip angle of each broken layer in the crushing chamber is 22 °.

Learn More

Leave A Reply