Rock Crusher - Eastman Rock Crusher

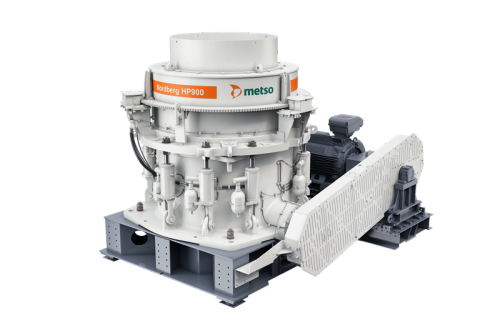

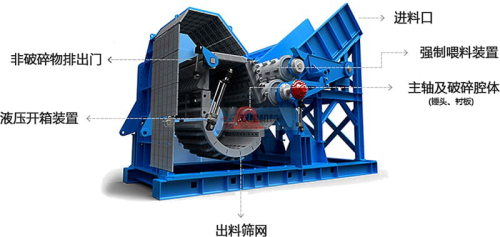

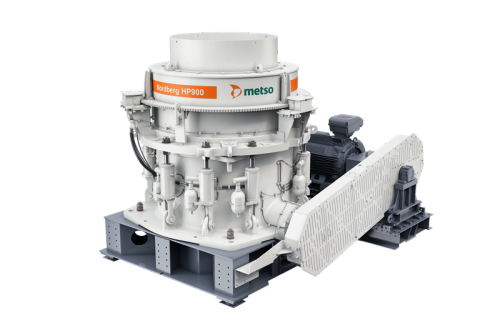

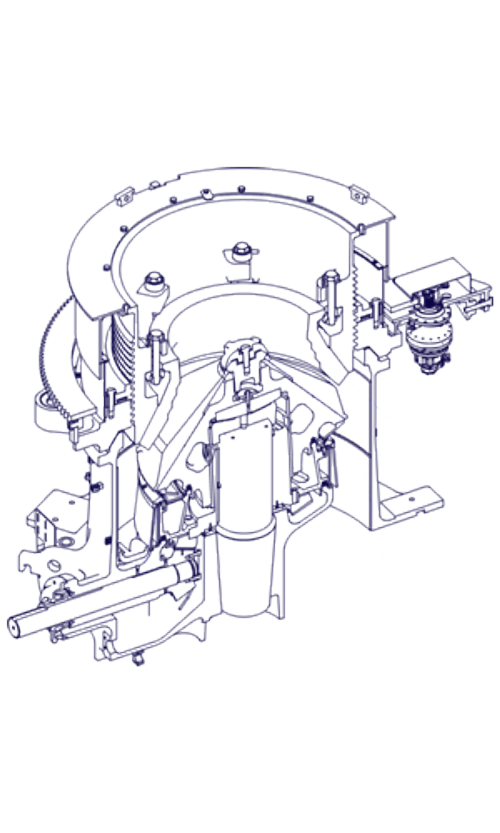

Jaw crushers are an excellent primary crusher when used to prepare rock for subsequent processing stages. Cone and gyratory crusher. These are also compression-type machines that crush material between a moving and a stationary piece of steel. The setting between the two pieces controls the output.

Learn MoreJaw Rock Crusher - BUILD Ep.5

Aug 20, 11K Dislike Share Description Donn DIY 847K subscribers Fabricating a jaw rock crusher from scratch. Making the toggle plate mount and fabricating a dedicated trailer using scrap

Learn Morejaw rock crusher | superior cone crusher countershaft bushing indonesia

Rock Small Jaw Crusher Stone Jaw Crusher Shunzhi High Quality Price Mini Gold Mining Machine Rock Stone Scale Portable Small 3TPH Pe 150*250 200*300 Jaw Crusher For Sale ,499.00- Jaw Crusher Plans | Rock crushers for inlay- powered and.

Learn MorePortable Rock Crusher / Aggregate Crushing Plant For Sale - New

Used 2000 TRIO 3242 Portable Jaw Crushing Plant, SN: C0000265701, mounted on three axle carrier with fifth wheel, air brakes, running lights, with a TRIO 40" X 16' Vibrating Grizzly Feeder with a 25 HP electric motor drive, a TRIO 3242 Jaw Crusher with a 200 HP electric motor drive, a 36" X 30' product discharge conveyor with a 15 HP electric motor, we have all electrical

Learn MoreHomemade Jaw Crusher - - Pinterest

Apr 17, - Would love to be able to make my own crushed stone and gravel. I have screened piles of rock while excavating my house site.

Learn MoreCrushers (New & Used Jaw Crushers, Impact Crushers, & Cone Crushers for

New & Used Jaw Crushers, Impact Crushers, & Cone Crushers for sale in Top Brands like Extec, , , Powerscreen, and more. Rock Crushers, Concrete Crushers, Stone Crushers, and more. Exclusive US home of Evortle Crushers. Small concrete crushers available new! Financing available upon request.

Learn MoreMobile jaw crushers | for pre-crushing | Kleemann

The crushing plants of the MOBICAT series are used for the precrushing of almost all natural rock and in recycling. However, the output of the MOBICAT

Learn MoreManual Rock Crushers - Gold Prospecting Mining Equipment Detectors

The CrazyCrusher brand Rock Crusher is 100 percent steel, and it is 100 percent made in the U.S.A. by 100 percent Americans! The jaws are made of 3/8 steel, and the face has horizontal welds across them that not only help grip and pull down rock pieces, it also prevents we the actual jaws.

Learn MoreJaw Rock Crusher - BUILD Ep.6 - IT'S FINISHED!

Aug 27, · Fabricating a jaw rock crusher from scratch. Finishing the trailer - cleaning up steel rims and changing tires, fabricating tow bar, making drawback rod and

Learn MoreJaw Crushers - Parker Plant

First stage, primary rock crushing plants. Parker have been engineering rock crushers for over 100 years and today thousands of jaw crushing machines and units

Learn MoreHome - Mt Baker Mining and Metals

World leader in design and manufacturer of small and medium scale hard rock ore processing and high-performance gravity concentration systems; The crusher (16″ x 24″ Jaw Crusher Module) is great! I probably have 300 hours on it and we are in the process of swapping around jaw plates. I am very impressed with your product and would have

Learn MoreJaw Crushers - high quality and reliability from RETSCH

The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and pre-crushing of mediumhard, hard, brittle and tough materials.

Learn MoreWhat is a Jaw Crusher? - MEKA Crushing Equipment

Jaw crushers are generally defined by their opening size. For example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mm. The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6. Settings and Damping Group 7.

Learn MoreJaw Crusher equipment simulation - Rocky DEM

Jaw crushers are equipment used to reduce the size of many different types of materials in many applications. Analyzing jaw crushers in CAE

Learn MorePortable Rock Crusher / Aggregate Crushing Plant For Sale - New & Used

Used 2000 TRIO 3242 Portable Jaw Crushing Plant, SN: C0000265701, mounted on three axle carrier with fifth wheel, air brakes, running lights, with a TRIO 40" X 16' Vibrating Grizzly Feeder with a 25 HP electric motor drive, a TRIO 3242 Jaw Crusher with a 200 HP electric motor drive, a 36" X 30' product discharge conveyor with a 15 HP electric motor, we have all electrical switching equipment

Learn MoreRollerjaw Rock Crusher - Tech Briefs

The rollerjaw rock crusher melds the concepts of jaw crushing and roll crushing long employed in the mining and rock-crushing industries.

Learn MoreK-JC503 Mobile Mini Jaw Crusher - Komplet America

The K-JC503 mobile jaw crusher is our most compact mini rock crusher machine, providing an ideal solution for construction companies, demolition contractors,

Learn MoreRock Jaw Crusher,High Quality Granite Jaw Stone Crusher

The Stone Crushing Plant mainly consists of Vibrating Feeder, Jaw Crusher, Cone Crusher or Impact Crusher, Vibrating Screen, Belt Conveyor and Control System, etc. It is completely capable to crush and screen limestone, marble, granite, basalt, river gravel and other hard stone materials, and produce sand & gravels with various granularities

Learn MoreLaboratory Jaw Crushers - Gilson Co

LC-28 3x4in Laboratory Jaw Crusher reduces 3in feed aggregate and rock material to a product with 50% passing 0.25in (6.3mm) sieve. Jaw opening quickly adjusts

Learn MoreDynamic Balancing Jaw Rock Crusher

Large jaw type rock crushers are very common in the stone and gravel business. They are generally portable and can be towed by tractor

Learn MoreHow does a Rock Crusher Work - Jaw Crusher - 911Metallurgist

Nov 22, · A jaw crusher is recommended for tough, abrasive, high compressive strength materials. Special machines have been designed for ores having compressive strength as high as 80,000 lbs per sq in. All-steel sectionalized frame. End members are box section. Deep side members of welded steel plate.

Learn MoreJaw Crusher | manufactor | thyssenkrupp Mining Technologies

Jaw crushers are used within the aggregates, cement, and mining industry, as they have been proven to be an efficient primary crusher for hard rock materials such as granite and others. The mining and cement industry also profit off their optimized crushing chamber. thyssenkrupp Mining Technologies jaw crusher types

Learn MoreMicro Concrete Crushers & Conveyors | Portable Rock

Discover Micro Concrete Crushers & Conveyors. Portable Rock, Concrete & Asphalt Crushing, Recycling Equipment with Cone & Jaw Crushers.

Learn MoreWhat Is a Jaw Crusher? Here's How It Works - Cutting Technologies

A jaw crusher essentially crushes large rocks to a more usable size. They're typically the first-line machinery used in the material reduction for several applications. This includes rock quarries, sand and gravel, construction aggregates, metallurgy, and chemical industries.

Learn MoreHow Does a Jaw Crusher Work - Kemper Equipment

All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary

Learn MoreJaw Crusher - Senya Crushers

The Senya 2 Portable Jaw Crusher has been designed personally by Senya Tech's Owner and Head Engineer, Mr. Jun Sui. This product has been years in the making, and the Senya 2 has been crafted with the highest care and foresight. Senya 2 Portable Jaw Crusher is the most efficient crusher for small scale crushing projects. Learn More

Learn MoreJC Series Jaw Crusher - Senya Crushers

The crusher is fixed by the device of special rubber shock absorber, which absorbs effectively the its vibration at the peak point and meanwhile, allows crusher to displace in vertical and horizontal direction. In this way, the shock to foundation would be reduced. WORKING PRINCIPLE OF JC SERIES JAW CRUSHERS: The motor drives belt and pulley.

Learn MoreJaw Crusher | Crushing Plant | Hard Rock Mining Equipment | DOVE

DOVE JAW CRUSHER FEATURES: High tonnage capacity of up to 1000 Tons/ Hour, and low operating cost. Designed for toughest rock material, with compressive strength of up to 320 MPa. Supplied for Primary coarse crushing and secondary Fine crushing, within the rock reduction plant. Wide range of closed side setting adjustment.

Learn MoreGME10 - Jaw Rock Crusher - Global Mining Equipment

Description: The GME10 Jaw Rock Crusher is a rock crusher that is designed to take larger rock and crush them down to 1" (25mm)

Learn MoreJaw Crushers - Best Models for 2022 - 911 Metallurgist

3″ x 4″ Gasoline Rock Crusher. US $12,000 $10,000.

Learn Morerock jaw crusher for sale: Search Result

220V Powered Jaw Crusher Hard Rock Mining Sampling Lab Assaying Crusher w/Motor. Brand New. $803.70. Was: $855.00 6% off. or Best Offer. +$269.00 shipping.

Learn More

Leave A Reply