Grate Coolers Modern Technology For Cement industry

1/4 · The grate type cooler is the most suitable cooler for pre-calciner kiln and for kilns with a high outputsNowadays grate cooler are designed for large kiln ca

Learn MoreGrate Cooler - Cement Grinding Plant Manufacturer from Yamuna Nagar

Rs 3.4 Lakh / Unit Get Best Price. Industrial Clinker Cooler is extensively used to cool the clinker and extracted heat from hot clinker is supplied at secondary and tertiary air to kiln. Acknowledged for its optimum specific grate load, this ensures lower heat consumption. It is basically supplied in two independent entities inlet stationary

Learn MoreGrate Cooler - INFINITY FOR CEMENT EQUIPMENT

Each section of the grate cooler that has its cooler own drive is independently controlled by the press of the first compartment or second under grate comp.

Learn MoreGrate cooler... In cement plant

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features Press Copyright Contact us Creators

Learn MoreClinker cooler replacement delivers improved productivity at

of its existing systems at the cement plant based in Ramapuram,. Mallacheruvu, Kodad in Nalgonda. They paid particular attention to the grate cooler,

Learn Morecross bar cooler in cement plant - Henan Technox Mining Machinery

Normally, the grate coolers are designed considering an operating cooling air flow of 2.2 - 2.4 kg (1.8 - 1.9 nm3) kg clinker to achieve clinker temperature of 65 0 c above ambient, at the cooler outlet. however, in many plants, especially at a lower production level than rated, the operating cooling air quantity is found to be on much.

Learn MoreClinker grate cooler - SlideShare

This presentation shows the principles of working of clinker coolers and gives some examples for GRATE COOLER (IN CEMENT PRODUCTION).

Learn MoreGrate cooler back-up insulation for cement plants - Skamol

Speciality insulation systems for grate coolers that increase and maintain high air-temperature between rotary kilns and Cement plant grate cooler

Learn MoreRed River in Cement Grate Cooler Red... - Cement.technology

Red river is a phenomenon in grate cooler; it is often a red hot narrow stream of fine clinker with a higher temperature than the neighbored clinker and appears far down in the cooler. The fact that especially large diameter type kilns tend to discharge fine clinker on the kiln's load side and coarse clinker on the opposite side can make it

Learn MoreTemperature control during clinker cooling process - VisionTIR

In the clinker cooler, the hot clinker is rapidly cooled by air in order to obtain Some cement plants incorporate into the cooler a boroscope inspection

Learn Moregrate cooler in cement plant

Horizontal Grate Cooler_Cement Production Line,Cement Machine , Description of Horizontal Grate Cooler: 2500 Tons/Day Dry Process Cement Plant. 100,000 Tons/Year Small Concrete Processing Plant. industrial Kiln and Furnace.

Learn MoreCement Cooler - Clinker Cooler | Types Of Clinker Cooler AGICO

The thermal efficiency of the grate cooler is 70%-75% and the temperature of secondary air is high, so it is a good choice for large scale cement production. The temperature of cooled clinker Since grate cooler is a type of quench cooler, the clinker can be treated by cooled air as soon as entering the machine.

Learn MoreClinker Cooler - Grate Cooler Latest Price, Manufacturers

Clinker Cooler · Dry Horizontal Flow Mild Steel Clinker Cooler ESP for Cement Plant, Automation Grade: Fully

Learn MoreGrate Cooler Clinker Cooling System In Cement Plant (Kiln

Grate Cooler Clinker Cooling System In Cement Plant (Kiln System Part 7) _ English VersionGrate Cooler System in the Clinker Production Process at the Cement

Learn MoreGrate Cooler - Clinker Cooler | AGICO Grate Cooler In Cement Plant

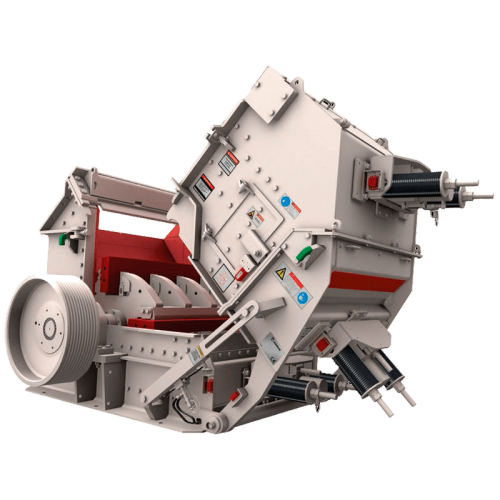

What Is Grate Cooler? Grate cooler, as a quench type clinker cooler, is the important cement equipment in the clinker calcination system. Its main function is to cool and transport cement clinker. Meanwhile, provide hot air for cement rotary kiln and precalciner.

Learn MoreGrate Cooler | Clinker Cooler Manufacturer | SINOMALY

Grate Cooler, Clinker Cooler. Clinker grate coolers are kiln cooling machines used to cool large quantities of hot clinker material rapidly.

Learn Moreperformance evaluation of a grate cooler in a cement ... - IJSEAS

Cement production in Ibese Cement Plant constitutes one of the major manufacturing industries in the Nigeria growing economy (Koroneos et al.,

Learn MoreWhite cement cooler - thyssenkrupp Industrial Solutions

Finish cooling from 600°C to the ultimate temperature of approx. 100°C is performed on the vibrating grate with air. Air cooling was deliberately chosen for

Learn Moregrate cooler for cement plant

Invest in brilliant grate cooler for cement plant at and boost your productivity. The grate cooler for cement plant are designed for cement production efficacy.

Learn MoreRotary Cooler for Small Cement Plants | Rotary Drum Coolers

Rotary Cooler in Cement Plant. Product Name: Rotary drum cooler / Rotary cooler. Diameter: 1.2 – 3 meters. length: 12 – 30 meters. Condition: brand new. Motor Power: 11 – 112 kW. SEND INQUIRY. Rotary coolers are a type of traditional cooling equipment in cement plants. They perform especially well on cement clinker cooling in small-scale

Learn MoreGrate Cooler - SBCCO-CEMENT

The clinker progresses through the cooler by moving along the grate, and so the direction of the cooling air is at right angles to the direction of the clinker's movement. The grate cooler functions as a cross-current heat exchanger. By this method, the clinker is cooled from 1300-1400℃ to 100℃ in just a few minutes. [/vc_column_text

Learn MoreGRATE COOLER (IN CEMENT PRODUCTION

12/4 · GRATE COOLER (IN CEMENT PRODUCTION) 1. Kelompok 6 1 2. Laela Riza K, 12210002 Anggi Sagitha P, 12210010 Fadlianor, 12210017 Khusnan Aji P, 12210023 Presented

Learn MoreGrate Cooler – SBCCO-CEMENT

The clinker progresses through the cooler by moving along the grate, and so the direction of the cooling air is at right angles to the direction of the clinker’s movement. The grate cooler

Learn MoreExperimental research on cement grate cooler system and

In this study, we analyze the heat distribution in the entire grate cooler system of a 5000 t/d cement plant through experiments, and acquire

Learn MoreCement Cooling System - Efficient, Industrial Cement Cooler | Solex - Solex

The cooling of cement is an important step prior to storage in mitigating gypsum dehydration and subsequent moisture liberation which can lead to lump formation. Recommendations vary but it is generally accepted that with mill outlet temperatures of around 110ºC - 120ºC, cooling to below 80ºC is necessary to avoid this reaction.

Learn MoreHigh Efficiency Grate Cooler , Less Leakage Clinker Cooler In Cement Plant

China High Efficiency Grate Cooler , Less Leakage Clinker Cooler In Cement Plant, Find details about China Grate Cooler from High Efficiency Grate Cooler , Less Leakage Clinker Cooler In Cement Plant - Anyang Best Complete Machinery Engineering Co., Ltd.

Learn MoreCN212457959U - Improved grate type cooler for cement plant - Google Patents

The utility model discloses an improved generation comb formula cooler is used in cement mill, including the box, the discharging pipe has been run through in the left side of box, and the right-hand member of discharging pipe runs through the box and extends to the inside of box, and the first driving motor of support frame fixedly connected with is passed through at the top of box internal

Learn MoreGrate Cooler | Clinker Cooler, Cement Cooler | Cement Plant

Grate cooler. Production Capacity: 600~10000 t/d. Heat recovery rate: ≥72%. Application: cement, silicate products, new building materials, etc. . The grate cooler is a

Learn MorePERFORMANCE EVALUATION OF A GRATE COOLER IN A

International Journal of Scientific Engineering and Applied Science (IJSEAS) – Volume-4, Issue-03, April ISSN: 2395-3470 www.ijseas.com 2 2.0 EQUIPMENT DESCRIPTION 2.1

Learn MoreGrate Cooler - CHAENG

The grate cooler is the main equipment in calcining system of the cement plant. Its main function is to cool and transport the cement clinker. It also provides hot air for rotary kiln and decomposing furnace, and it is the main equipment for heat recovery in calcining system. Grate cooler of CHAENG is new energy-saving clinker cooling equipment

Learn MoreCEMCAP D2.13 Clinker Cooler Film - European Commission

CEMCAP, cement plant, clinker, cement, industry, clinker cooler, oxyfuel, technology, carbon capture, carbon dioxide, CO2, experiment,

Learn More

Leave A Reply