Heat Exchange Modeling of a Grate Clinker Cooler and

PDF | The concept of the exergy analysis is applied to a grate cooler of a cement production facility. The cooling of the clinker is

Learn MoreGRATE COOLER - Xinxiang Great Wall Machinery Co., Ltd - PDF Catalogs

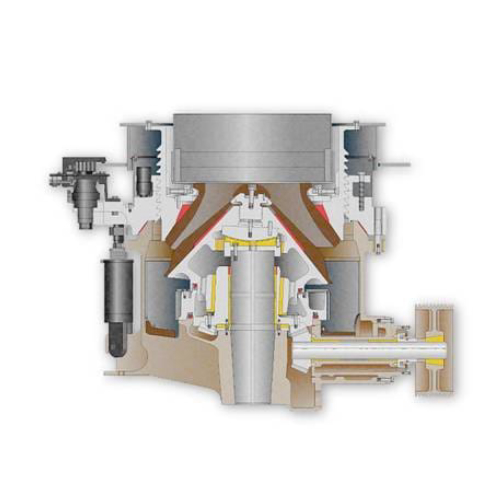

Grate cooler of CHAENG is new energysaving clinker cooling equipment, which adopts international advanced flowcontrol technology, makes continuous optimization and development relying on advanced thermal technology. Its output can be improved by 20% compared with traditional grate cooler. Heat consumption can be saved more than 10%.

Learn MoreHEAT EXCHANGE MODELING OF A GRATE CLINKER

The concept of the exergy analysis is applied to a grate cooler of a cement production facility. The cooling of the clinker is.

Learn MoreCOOL DOWN - IKN

be the number one choice for clinker cooling technology. The initial development of the IKN Pendulum Cooler® started more than 30 years.

Learn MoreThermodynamics and Parametric Study of the Grate

In cement industries, grate coolers are commonly used for heat thermodynamics efficiencies of a cooling system for grate cooler.

Learn MoreCoolax Grate Cooler FLS | PDF - Scribd

The COOLAX high efficiency grate cooler the grate plates through a system of ducts After the CFG zone comes the after-cooling has greatly improved heat

Learn MoreUS5330350A - Reciprocating grate cooler - Google Patents

The invention relates to a reciprocating grate cooler in which the drive arrangement is enclosed by a drive housing, the interior of which is closed off so as to be airtight against the atmosphere, but by contrast has a pressure equalization connection to the interior of the cooler housing. Such a reciprocating grate cooler is distinguished by a substantially reduced expenditure for the

Learn MoreClinker Cooler - Mineral Processing & Metallurgy

28/11/ · Clinker Cooler. The Air-Quenching shaking grate Clinker Cooler was developed more than 20 years ago as an improved heat recuperating cooler for use with rotary kilns. It was designed to air quench and cool large quantities of hot clinker rapidly, and to recover and return to the kiln a major portion of the heat from the clinker.

Learn MoreNumerical Simulation of an Improved Structure for High

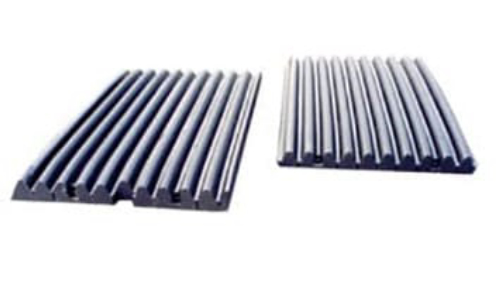

The grate plate is the main sector of the grate cooler, and its structure can be modified to receive electric power while cooling the clinker.

Learn MorePDF Mass and Energy Balance in Grate Cooler of Cement Plant - ijsetPDF

A grate cooler can be regarded as a simple heat exchanger through which the clinker passes across or counter to the cooling air flow and a direct heat transfer takes place between the hot clinker and the cold cooling air. The desired maximum recuperation of the heat from the clinker cooler for use in the

Learn MoreGrate kiln pelletizing plant - Outotec

The Grate, the Kiln and the Cooler. The object of the process is to transform the pelletized concentrate into hardened pellets that can be used as blast furnace feed or direct reduction furnace feed. The Travelling Grate is where pellets are dried and then heated up to a temperature of about 800-900 deg C. The heat used to dry and preheat the pellets is typically hot air pulled

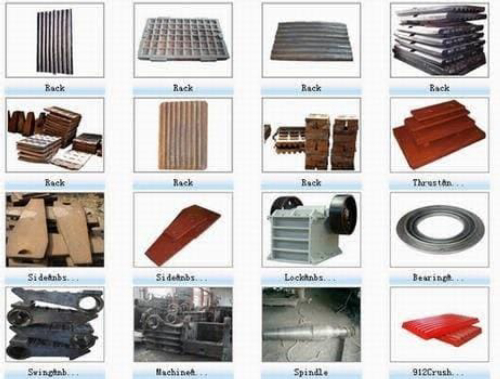

Learn MoreGrate Coolers | PDF | Bearing (Mechanical) | Screw

01/13/22 12. fFixed Inlet Grate. Objective of Fixed inlet grate is to create a. homogeneous clinker bed of uniform. resistance against the passage of air. 5 to 6 Rows of Fixed grates (3 meter) are

Learn MoreXCC Cooler Grates

complete grate, the net wear rates are respectively 2.59 and 0.67. Xcc® grates are thus 3.85 times better in average than the ones in standard alloys. air channels in Magotteaux patented Bar Grate Comparison between standard alloy and Xcc® in a 3,100mtpd cooler. RGTHQTCVGF left: Xcc® grate. right: competition grate both after 26 months

Learn MoreGrate cooler for a cement clinker kiln - EP 2559961 A1

for cooling and transporting of cement clinker and grate onto a grate cooler where it is cooled by cooling air and.

Learn MorePDF Cooler Grate Motion Control GMC - claudiuspeters.comPDF

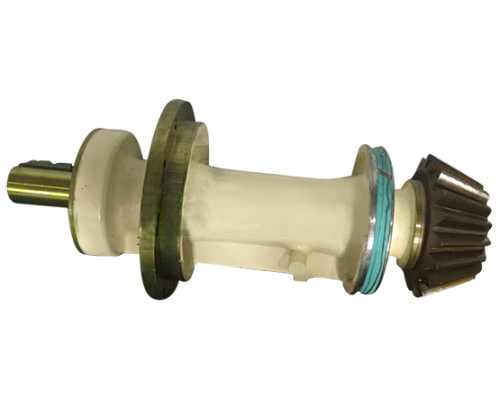

The Grate Motion Control box (GMC) is a major part of the hydraulic grate drive of Claudius Peters clinker coolers. One GMC is used for each cooler grate. The GMC converts the master signal of the 'clinker bed height' control loop into a control signal, which changes the grate speed (number of strokes) via a hydraulic proportional valve.

Learn MoreGrate Cooler - Chanderpur

Grate Cooler. Industrial Clinker Cooler is extensively used to cool the clinker and extracted heat from hot clinker is supplied at secondary and tertiary

Learn MorePDF designer and Manufacturer Company in Iran. - GreenIDPDF

The grate is driven by cylinders placed on either side of the cooler. The hydraulic drives consist of axial piston pumps with electro hydraulic servo adjustment of the oil flow to the cylinders which have built in linear transducers. The system is controlled by a PLC .The pump units have built flow and its direction.

Learn Moreclaudius-peters-eta-cooler-brochure-en.pdf

ETA (η) Cooler totally encapsulates the evolution of clinker cooling in one complete system. Claudius Peters began by marketing the grate cooler in.

Learn MoreGrate Drive - IKN

20/02/ · The grate drive is located outside the cooler housing, protected from contamination by clinker dust and with improved accessibility for maintenance. Depending on the size of the cooler either a single drive or a synchronized twin drive is installed. IKN grate drives are available as hydraulic or electro-mechanical drive system (DLD-Dynamic

Learn MorePDF Mass and Energy Balance in Grate Cooler of Cement PlantPDF

A grate cooler can be regarded as a simple heat exchanger through which the clinker passes across or counter to the cooling air flow and a direct heat transfer takes place between the hot clinker and the cold cooling air. The desired maximum recuperation of the heat from the clinker cooler for use in the

Learn MorePDF Latest Developments in High Efficency Clinker CoolingPDF

ETA Cooler Grate Cooler Cooler Efficiency @ 0,85 Nm³/kg recuperation air 77,8 % 73,9 % Wear Grate plates 100 % in clinkerProtection Autogenous protection Due to pebble layer Heat Protection Safe due to higher clinker bed and pebble lane filling Direct contact between hot clinker and grate plate Stroke Length

Learn MoreEP0473885A1 - Grate cooler - Google Patents

The aim of the invention is to design a grate cooler in such a manner that the device used to support the swing frame (1) on the stationary abutment (2) can be manufactured simply and is practically maintenance-free in operation. The grate cooler according to the invention has to this end a swing frame (1) for driving movable grate plates, which is movable to and fro in the conveying direction

Learn MorePDF Research on Control Mechanism Model of Grate Cooler Based on Seepage ...PDF

moves slowly on grate bed. Cooling air blows into the clinker layer vertically from the bottom of the clinker, permeates and diffuses in the clinker to cool the red-hot clinker. Cooling air becomes hot air after exchanging heat energy with clinker. Fig. 1: The schematic diagram of grate cooler Fig. 2: Physical model of grate cooler

Learn MoreA Self-tuning Fuzzy PID Control Method of Grate Cooler

Keywords: self-tuning fuzzy PID, Kalman filter, grate cooler. 1. Introduction. Clinker cooling process is the key process in cement production which cool

Learn MorePDF) Analysis on Balance Improvement of Cross Grate Cooler Assembly

company cross grate cooler is mainly composed of 10 working procedures, which are as follows: pre- assembly, welding, painting, installation of driving guide rail, assembly, installation of vents,

Learn MorePDF Cross-Bar® Cooler The Art of Cooling Clinker - FLSmidthPDF

Replacing worn grates or carrying out gap management on grate type coolers are time-consuming exercises and an on-going expense. In the Cross-Bar® cooler, clinker is moved through the cooler using horizontal bars that operate in a shuttle motion across a number of lanes. This effectively conveys, mixes and shears the

Learn MoreResearch on Modelling of Grate Cooler Based on Typical

The grate cooler is the main equipment for clinker cooling and heat recovery in the sintering process of cement clinker, and maintaining the grate cooler.

Learn MoreConversion to High-Efficiency Grate Coolers

The grate cooler is integral to heat recovery from the clinker, so grate coolers that operate with higher efficiencies will lead to less wasted heat and

Learn MoreGrate Cooler in Cement Plant | Cement Clinker Cooler for Sale

The grate cooler belongs to the family of air quench cooler (AQC). The clinker fed into the grate cooler can be quenched from 1300-1400 ℃ to below 100 ℃ in just a few minutes. The grate cooler can be further divided into three types: the rotary grate cooler, the traveling grate cooler, and the reciprocating grate cooler.

Learn MorePDF 13GREENID A Self-tuning Fuzzy PID Control MethodPDF

the control model of grate cooler was obtained by system identification. It was shown that this method could inhibit the influence of noise of pressure signals, could enhanced adaptive capability of controller and could improved heat energy recovery efficiency of grate cooler. Keywords: self-tuning fuzzy PID, Kalman filter, grate cooler 1.

Learn MoreGrate Cooler | Clinker Cooler, Cement Cooler | Cement Plant

Grate cooler. Production Capacity: 600~10000 t/d. Heat recovery rate: ≥72%. Application: cement, silicate products, new building materials, etc. . The grate cooler is a

Learn More

Leave A Reply