how much is high efficiency gyratory screen machine for quartz sand

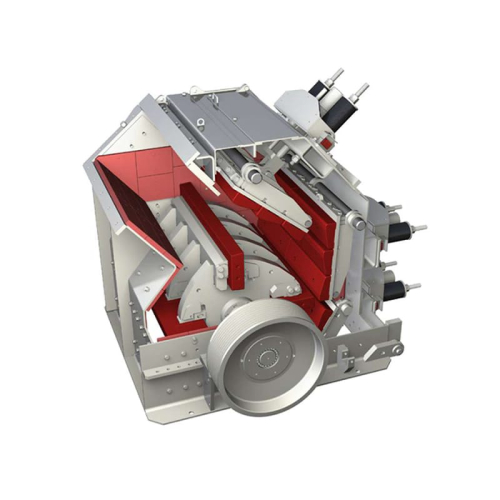

Hammer crusher consists of a high-speed, usually horizontally shaft rotor turning inside a cylindrical casingThis size machine will handle ore with a maximum size of 1.22 m at a crushing rate of approximately 725th However, at crus hing rates above 545th ~ with a 203mm set. 1 the economic advantage of the jaw crusher over the gyratory

Learn MoreHigh Efficiency Ore Gyratory Crusher For Mining Plant

30/08/ · Crusher Machine, Cone Crusher, Steel Slag Crusher manufacturer / supplier in China, offering High Quality and Low Price Gyratory Crusher for Mining, Cylinder Stone/Sand/ Aggregate Washing Machine (YTX1530), High Efficiency Spring Cone Crusher Granite and so on.::: Mining Machine Vertical Shaft Rock Stone Impact Crusher Description of Impact

Learn MoreGyratory Crusher - an overview | ScienceDirect Topics

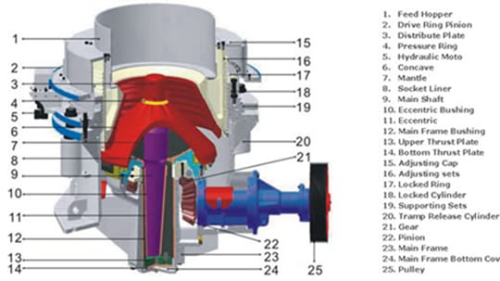

The gyratory crusher shown in Figure 2.6 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower

Learn MorePDF Mining crushers SuperiorTM MKIII Primary Gyratory - MetsoPDF

world combine to create a Primary Gyratory crusher with the best performance, highest capacity and highest reliability. Outotec's line of Superior™ Primary Gyratory crushers are designed to meet the demand for high efficiency and high capacity mining installations. Superior™ MKIII is the first high speed Gyratory. The new

Learn MoreGyratory Crusher-MECRU

The gyratory crusher is a large crushing machine that utilizes the gyratory motion of the crushing cone in the cone cavity of the shell to produce extrusion, splitting and bending effects on the material, and to coarsely break various hardness ores or rocks. Its crushing action is continuous, so the working efficiency is higher than that of

Learn MoreSuperior™ MKIII Series primary gyratory crushers - Outotec

Superior™ MKIII Series is the third generation of the Superior™ primary gyratory crushers. The latest generation is again better, more efficient, safer, and simpler than the previous one. Superior™ crushers are most often used in mining operations. The product family was developed especially to meet the needs of customers facing ever

Learn MoreHigh-Efficiency Cone Crusher ZI Cone Crusher | ANSWERS

High-Efficiency Cone Crusher ZI Cone Crusher , a Kawasaki Group company that manufactures crushing and grinding equipment, has an

Learn MoreHigh Efficiency Ore Gyratory Crusher For Mining | Dewo mobile crusher

gyratory crusher efficiency. Mining Technology FL s new digital. We remain steadfast in our aim to reduce emissions from mining to zero by 2030 Increasing the sustainability of key equipment like the gyratory crusher is part of our core goal to invest in efficiency-focused R amp D to deliver the best available equipment to the minerals industry Chris Reinbold Head of Global Product Line

Learn MoreGyratory Crusher Explained - saVRee

A primary crusher is designed to receive run-on-mine (ROM) rocks directly from the mines. Gyratory crushers typically crush to reduce the size of aggregate ; to

Learn MorePDF) A Gyratory Crusher Model and Impact Parameters

PDF | The objective of this research was to develop a mathematical model for gyratory crushers to help in the prediction of energy

Learn MoreGyratory Crusher Liners

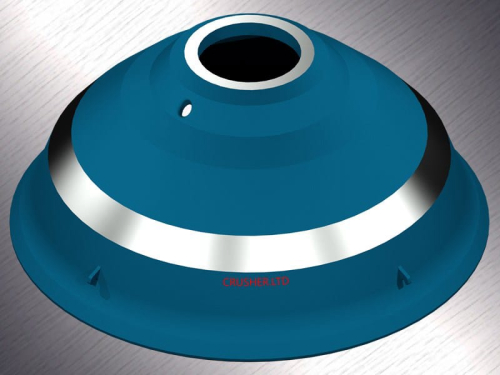

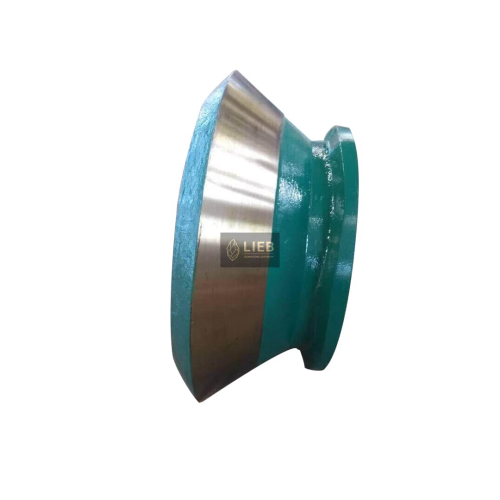

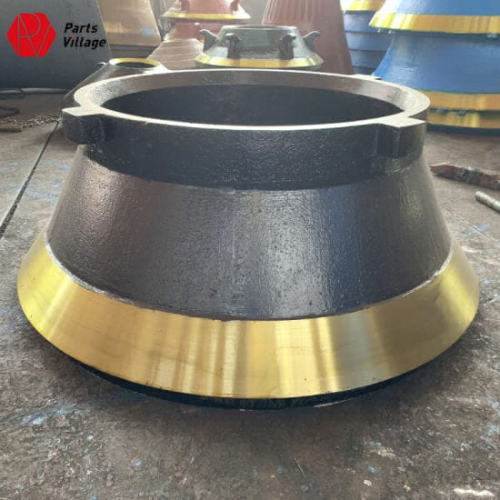

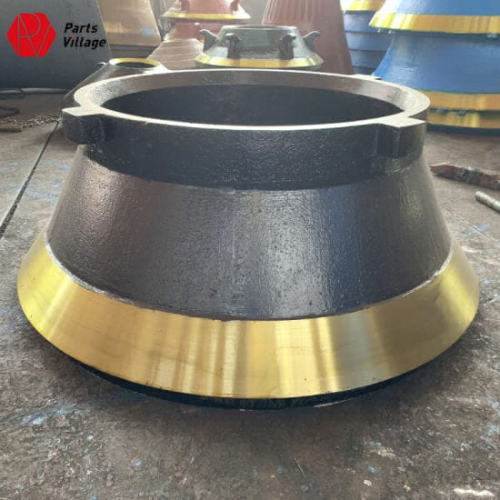

Maximise your crushing productivity with proven Gyratory Crusher Liners. Our Gyratory Crusher Liners are focused on serving you and your operation and are tailored specifically to your needs and goals. Rely on our knowledge, engineering and

Learn MoreDifference Between Jaw Crusher and Gyratory Crusher - JXSC

Some of the crushing ratios can reach 13.5, and the work is smooth, vibration is small. Jaw crusher is intermittent crushing, crushing efficiency is relatively

Learn MoreTips for maintaining efficiency in crushing circuits - Quarry

Ideally, the reduction ratio of a jaw crusher should be 6:1. There are different ways to calculate reduction ratio, but the best way is

Learn MoreGyratory Crusher | Jaw Crusher Manufacturer | CITIC HIC

Our crushers have been exported to a number of countries such as Sweden and Brazil, and widely used in coarse crushing operations of iron ores, copper ores, gold ores and molybdenum ores. Numerous projects that we have successfully executed are the evidence of our ability to provide safe, reliable, energy-saving and high-efficiency crushing

Learn MoreAMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Crushers have more efficient transfer of applied power to the breakage of rock than grinding mills. Gyratory crushers are operated in open circuit. The feed is limited to 1 to 1.5 meters in size. Thus, based on reduction ratio, the rock size is reduced to 10 to 15 cm.

Learn MoreCone Crusher - an overview | ScienceDirect Topics

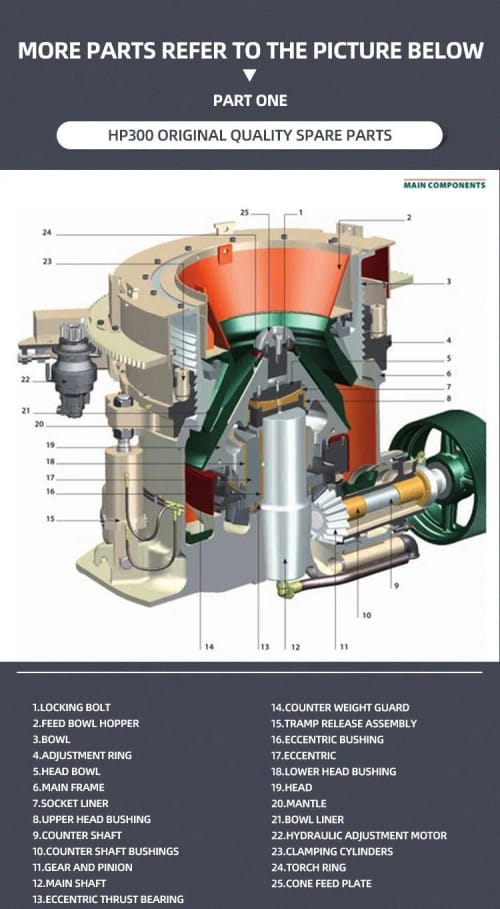

Maintenance of the wear components in both gyratory and cone crushers is one of the major operating costs. Wear monitoring is possible using a Faro Arm (Figure 6.10), which is a portable coordinate measurement machine.Ultrasonic profiling is also used. A more advanced system using a laser scanner tool to profile the mantle and concave produces a 3D image of the

Learn Moregyratory crusher pdf | high efficiency coal mill part

Gyratory Crusher,Cone Crushing Plant,Gyratory Breaker-Cone Gyratory Crusher. PDF. Gyratory crushers is widely used in mining, Each crusher is designed to work with. hammermill crusher eccentric bushing wearing copper bushing crusher s&h4800 spare part primary crusher for mining spare main shaft step figure part number search

Learn MoreCG800i Gyratory Crushers — SRP

CG800i crushers are built to be robust, reliable and efficient. Connected to My , they revolutionize availability and optimize uptime by giving you actionable insights into how the crusher is performing. CG810i Gyratory crusher: 128 (141) 1,067 (42) 1,300-2,700 (1,430 - 2,970) CG820i Gyratory crusher: 244 (268) 1,372 (54

Learn MoreGyratory Mining Gold Rock Marble Stone Aggregator Hydraulic Compact

Gyratory Mining Gold Rock Marble Stone Aggregator Hydraulic Compact Coal Grading Sieve Sand Making Cone Crusher Machine Parts , Find Complete Details about Gyratory Mining Gold Rock Marble Stone Aggregator Hydraulic Compact Coal Grading Sieve Sand Making Cone Crusher Machine Parts,Gyratory Stone Gold Ore Perlite Diesel Engine Tin Aggregator Pulverizer Mill Cone Crusher Mining Machine Parts

Learn MoreGyratory Crusher Pro | manufactor | thyssenkrupp Mining

thyssenkrupp gyratory crushers represent today’s state-of-the-art. They are designed for high performance and, at the same time, cost-effective operation, i.e. low servicing and

Learn MoreBasics of gyratory crushers | IMS Engineering (Pty) Ltd

Discover the basics of primary gyratory crushers and why you should and supplied by world-leading brands for guaranteed efficiency.

Learn MoreCG810 Primary Gyratory Crusher For Maximum Efficiency

CG810i crusher offer excellent reliability and safer & faster maintenance – up to 30% faster than competing crushers. A robustly designed one-piece main shaft and reinforced shells are made for tough use. The one-piece spherical spider bearing offers 5 times longer wear life than competing spider bushing design.

Learn MoreGyratory Crushers - Dorr-Oliver Eimco - PDF Catalogs

These gyratory crushers have been operating successfully in some of the world's harshest conditions for 50+ years. This long operating life can be attributed to the robust design that still utilizes to this day. Custom Designs, and Parts Options to improve the operational efficiency and scheduled maintenance practices of your

Learn MoreGyratory Crusher (TS) for harsh environments

The Gyratory Crusher TS is a high quality, modern design, durable gyratory crusher that was engineered from the ground up with an unwavering focus on performance, safety, maintenance and functionality, for the utmost reliability and efficiency in your projects. The Gyratory Crusher TS is distinguished from other gyratory crushers by its

Learn MoreGyratory Cone Crusher Manufacturer | Propel Industries

The Gyratory Cone Crusher delivers increased capacity with reduced maintenance and downtime. It guarantees trouble-free operation in varying feed conditions with a high reduction ratio. The AVC Series of Propel Cone Crusher offers the higher crushing efficiency and end product quality with lower Read More. GYRATORY CONE CRUSHER.

Learn MoreSuperior™ MKIII Series primary gyratory crushers

Outotec's Superior™ MKIII primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation.

Learn MorePeak performance from 's new Superior MKIII primary

The SuperiorTM MKIII gyratory crusher is based on 's trusted crushing technology enabling a low cost per ton through energy efficiency,

Learn MoreCrusher Efficiency Calculations - Mineral Processing & Metallurgy

Quarry rock of 12 in. maximum size is to be handled in a two-stage crusher plant at the rate of 70 tons per hour. The maximum size of output is to be 1½ in., and separation of materials over 1 in. size and the minus 1 in. in the output is required. Select a jaw crusher like those included in this table.

Learn MoreSuperior™ MKIII 62-75 primary gyratory crusher - Outotec

The latest Superior™ MKIII primary gyratory crushers generation is again better, more efficient, safer, and simpler than the previous one. It was developed

Learn MoreCG810 Primary Gyratory Crusher For Maximum

CG810i Gyratory crusher. CG810i crusher is built to be robust, reliable and efficient. Connected to My , they revolutionize availability and

Learn MoreGyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

Gyratory Crusher Pro - The next Generation Gyratory crusher KB 54-75 for iron ore The backbone of crushing technology with throughput rates of up to 15,000 t/h When it comes to crushing blasted hard rock in ore and natural stone mining, the efficiency of thyssenkrupp gyratory crushers in primary crushing is second to none.

Learn More

Leave A Reply